- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

600

-

Voltage:

-

110-240V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CHLB

-

Dimension(L*W*H):

-

3900*850*1500

-

Description:

-

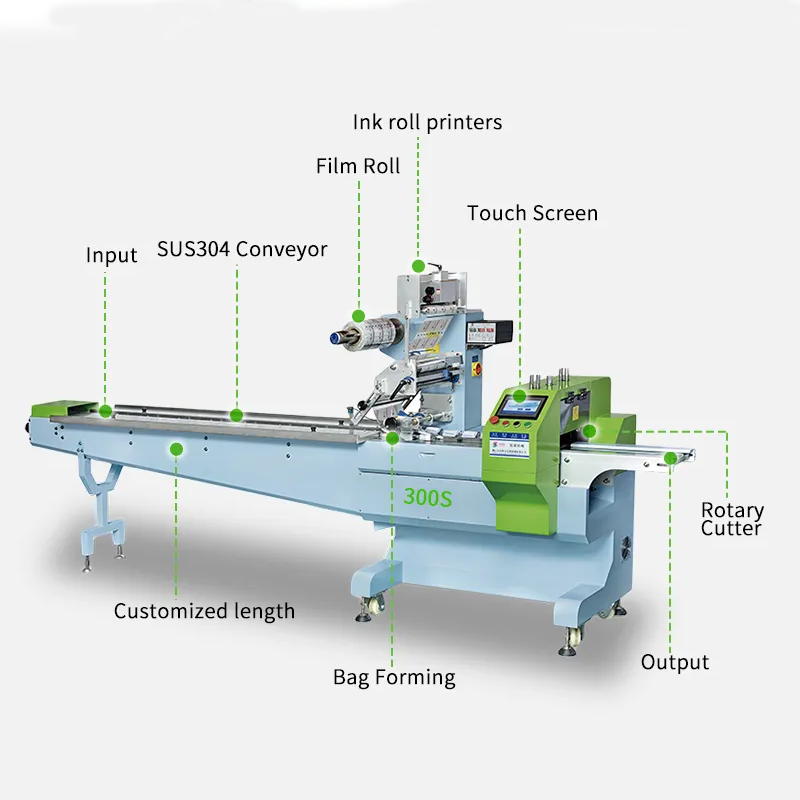

High speed horizontal pillow packaging machine

-

Advantage function1:

-

No product no pouch

-

Advantage function2:

-

Product-cut prevention

-

Advantage function3:

-

99 groups of parameters storage

-

Product contact surface:

-

Made of 304 stainless steel

-

Outer screw:

-

Full stainless steel

-

Film position:

-

Upper

-

Thickness of machine board:

-

4mm

-

Model:

-

300S

-

HMI:

-

7" touch screen

Quick Details

-

Function:

-

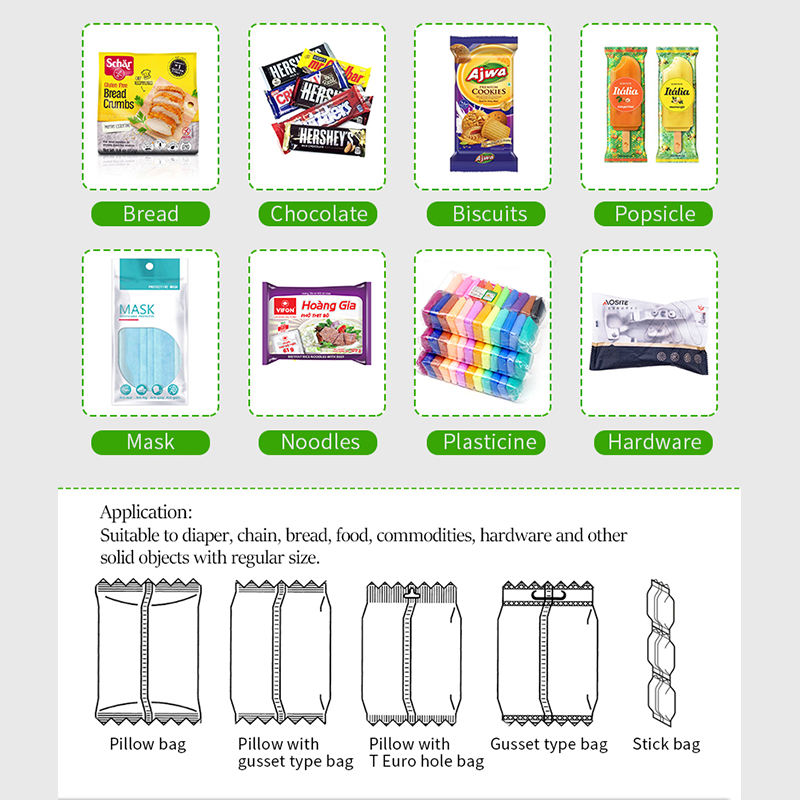

FILLING, Wrapping, Labeling, Laminating, Capping, COATING, Sealing, BOXING, Embossing, Gluing, SLITTING, counting

-

Packaging Type:

-

Stand-up Pouch, Bags, Film, Pouch

-

Packaging Material:

-

Plastic, Paper

-

Weight (KG):

-

600

-

Voltage:

-

110-240V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CHLB

-

Dimension(L*W*H):

-

3900*850*1500

-

Description:

-

High speed horizontal pillow packaging machine

-

Advantage function1:

-

No product no pouch

-

Advantage function2:

-

Product-cut prevention

-

Advantage function3:

-

99 groups of parameters storage

-

Product contact surface:

-

Made of 304 stainless steel

-

Outer screw:

-

Full stainless steel

-

Film position:

-

Upper

-

Thickness of machine board:

-

4mm

-

Model:

-

300S

-

HMI:

-

7" touch screen

Multi-function Automatic Horizontal Packaging Frozen Wet Macaroni Pasta Fresh Instant Ramen Noodle Spaghetti Packing Machine

|

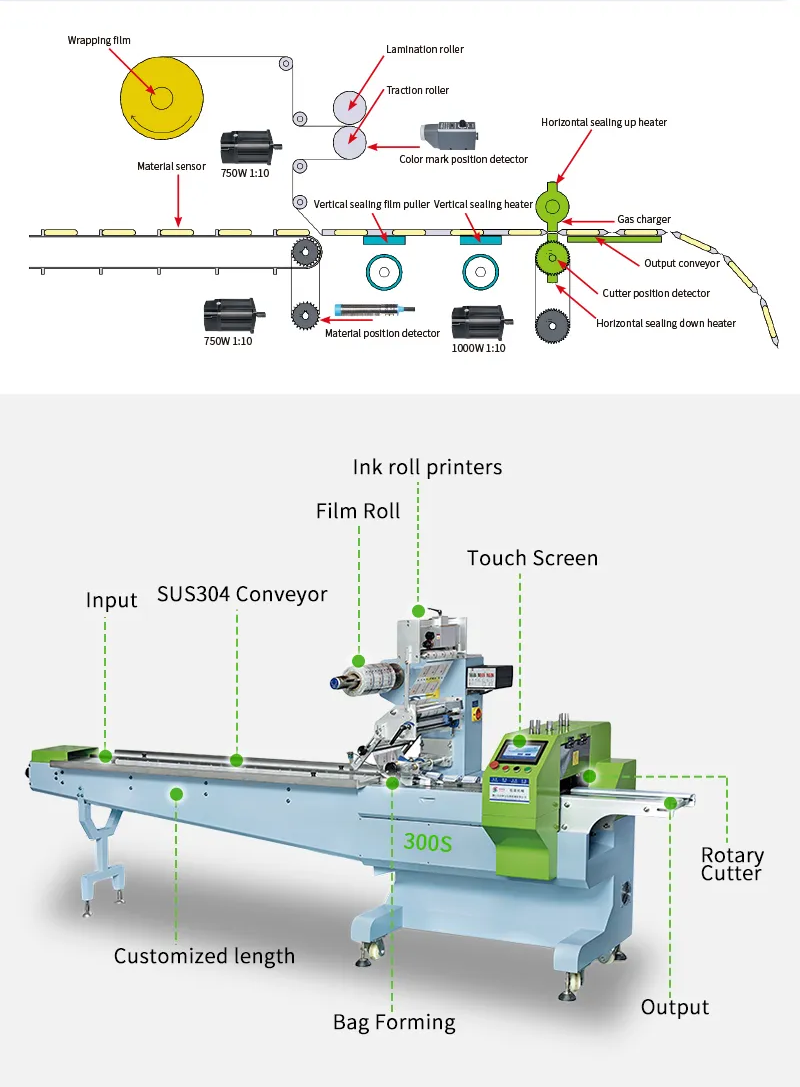

Horizontal Packing Machines Parameters

|

|

|

|

|

||||

|

Model

|

CB-300S

|

CB-350S

|

CB-450S

|

CB-500S

|

||||

|

Width of film

|

≤300mm

|

≤350mm

|

≤450mm

|

≤500mm

|

||||

|

Thickness of film bobbin

|

30-75um

|

30-75um

|

30-75um

|

30-75um

|

||||

|

Dimension of film roll

|

Outer:

diameter≤300mm,

Inner:

diameter≤75mm

|

Outer:

diameter≤300mm,

Inner:

diameter≤75mm

|

Outer:

diameter≤300mm,

Inner:

diameter≤75mm

|

Outer:

diameter≤300mm,

Inner:

diameter≤75mm

|

||||

|

|

|

|

|

|

||||

|

Single blade bag size

|

L

(50-6000)*

W

(50-140)*

H

(3-60)mm

|

L

(50-6000)*

W

(50-165)*

H

(3-60)mm

|

L

(60-6000)*

W

(25-215)*

H

(10-65)mm

|

L

(60-6000)*

W

(50-240)*

H

(10-80)mm

|

||||

|

Single blade packing speed

|

10-100bags/min

|

10-100bags/min

|

10-100bags/min

|

10-100bags/min

|

||||

|

Double blade bag size

|

L

(50-6000)*

W

(50-140)*

H

(3-55)mm

|

L

(50-6000)*

W

(50-165)*

H

(3-55)mm

|

/

|

/

|

||||

|

Double blade packing speed

|

20-200bgs/min

|

20-200bgs/min

|

/

|

/

|

||||

|

Power requirement

|

220V/50Hz, 3.8KW

|

220V/50Hz, 3.8KW

|

220V/50Hz, 4.6KW

|

220V/50Hz, 4.6KW

|

||||

|

|

|

|

|

|

||||

|

Machine size

(L*W*H)

|

3900*850*1500

mm

|

3900*850*1500

mm

|

3900*850*1500

mm

|

4100*1050*1500

mm

|

||||

|

|

|

|

|

|

||||

|

Machine Weight

|

600KG

|

600KG

|

810KG

|

810KG

|

||||

|

Motor configuration

|

Servo

|

Servo

|

Servo

|

Servo

|

||||

|

Film running way

|

From top

|

From top

|

From top

|

From top

|

||||

|

Cuting ways

|

Rotary cut

|

Rotary cut

|

Rotary cut

|

Rotary cut

|

||||

|

Sealing

|

Back seal

|

Back seal

|

Back seal

|

Back seal

|

||||

|

Remark:Any other customized sizes request, please contact us.

|

|

|

|

|

||||

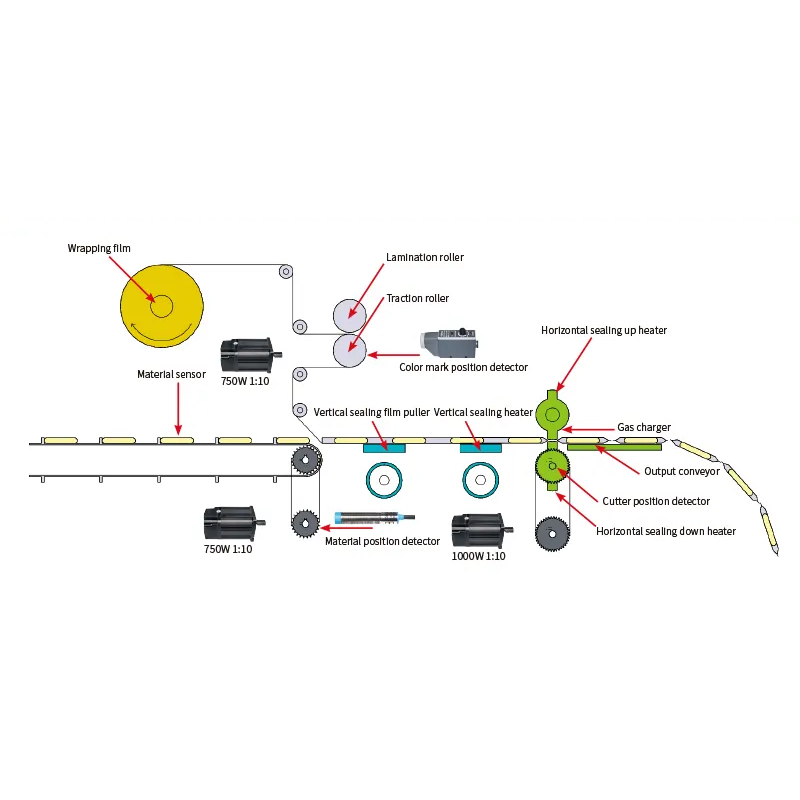

Features :

1.

3 Servo motor control (feeding mechanism, film feeding mechanism, knife sealing mechanism).

2.

Motion controller that responds quickly to various commands.

3.

Precise positioning of products.

4.

Independent temperature control for center seal mechanism and knife seal mechanism.

5.

The part in contact with the product is made of 304 stainless steel.

6.

Touch screen control.

Advantages :

1.

Touch screen interface:

parameter setting is simple and convenient.

2. Anti-air bag function:

there is product start packaging, no product stop waiting, saving packaging film.

3.

Anti-cutting function:

when the product is cut, the knife seat is reversed, the machine stops, and the knife seat is not damaged.

4. Memory function:

can store 99 sets of packaging parameters (product position, packaging speed, bag length).

5. Unlimited product length.

PRODUCT DETAILS

APPLICATIONS

COMPANY INFORMATION

PRODUCTION PROCESS

CERTIFICATE

EXHIBITION & CUSTOMER PHOTOS

PACKAGING & SHIPPING

FAQ

Q1: Are you a factory?

A1: Yes, we established in 1998 as a manufacturing supplier with 25 years experience. We can provide you with professional product packaging solutions.

Q2: What info you need before confirming the machine?

A2: Your product picture, your product size(length, width, height, weight etc.), packing type(Back seal/ quad seal/ 3-side seal/ 4-side seal etc), your product samples(for testing).

Q3: What is the material of contact food/material parts?

A3: The contact food/ material parts are made of 304#stainless steel. The machine body can be 304#stainless steel or carbon steel.

Q4: Can this machine make different bag sizes?

A4: One former can make one bag width, and the bag length can be adjustable within a range. It should be ordered an extra former if you want to make the other bag width.

Q5: Does your company accept OEM?

A5: Yes, we have a professional design and technical team to accept customization.

Q6: When you can deliver the machine after the order is placed?

A6: We usually can arrange shipment after 30-40 working days, but it depends on the quantity of the products.

Q7: How about your warranty?

A7: We provide 13 months warranty, starts from the issue date of bill of lading.

Q8: What can you provide after service?

A8: We can provide machine testing video and pictures before delivery, English manual, some free spare parts, installation in clients' factory and technical training.

Q2: What info you need before confirming the machine?

A2: Your product picture, your product size(length, width, height, weight etc.), packing type(Back seal/ quad seal/ 3-side seal/ 4-side seal etc), your product samples(for testing).

Q3: What is the material of contact food/material parts?

A3: The contact food/ material parts are made of 304#stainless steel. The machine body can be 304#stainless steel or carbon steel.

Q4: Can this machine make different bag sizes?

A4: One former can make one bag width, and the bag length can be adjustable within a range. It should be ordered an extra former if you want to make the other bag width.

Q5: Does your company accept OEM?

A5: Yes, we have a professional design and technical team to accept customization.

Q6: When you can deliver the machine after the order is placed?

A6: We usually can arrange shipment after 30-40 working days, but it depends on the quantity of the products.

Q7: How about your warranty?

A7: We provide 13 months warranty, starts from the issue date of bill of lading.

Q8: What can you provide after service?

A8: We can provide machine testing video and pictures before delivery, English manual, some free spare parts, installation in clients' factory and technical training.

Hot Searches