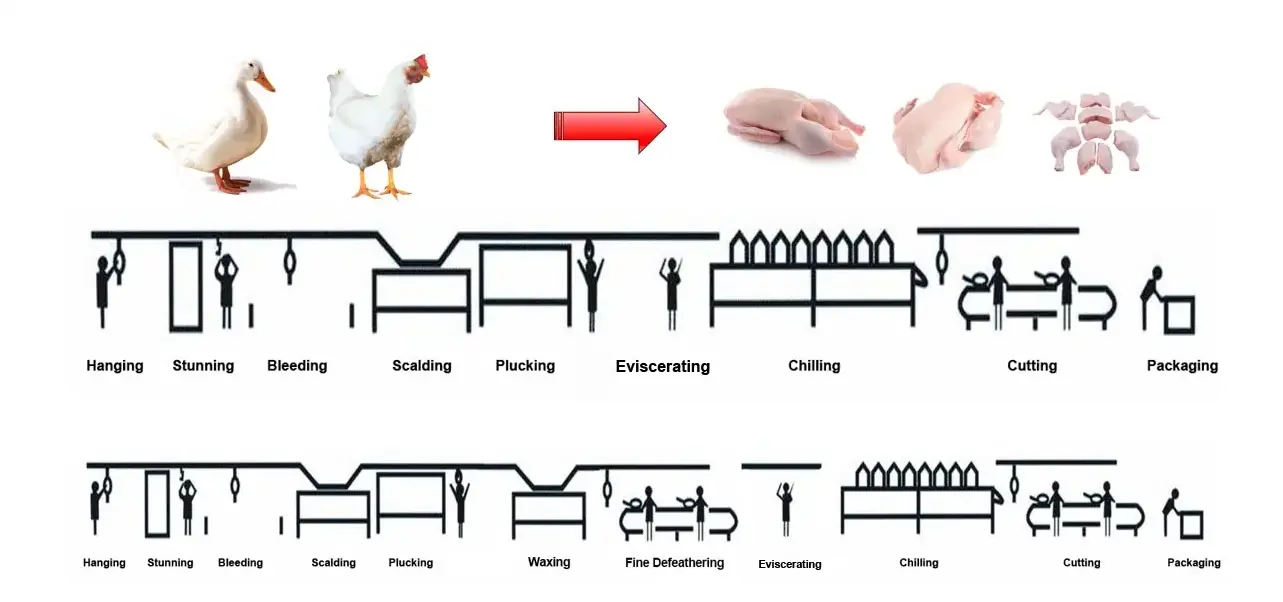

A Poultry Slaughter Plant basically comprises different slaughter equipments, conveying rails, cutting line, and cold rooms,

harmless treatment system and waste water treatment system. We can supply all these to our clients and privide a one-stop solution

for their slaughter plant or meat processing factory.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

customized

-

Weight:

-

3500 KG

-

Marketing Type:

-

Hot Product 2020

-

Name:

-

Poultry Processing Plant With Slaughter Equipment

-

Usage:

-

Chikken .goose .duck

-

Suit for:

-

Polury

-

Function:

-

Chicken Abattoir Equipment

-

Processing:

-

Complete Slaughter Line

-

Material:

-

Galvanized\stainless Steel

-

Object:

-

Slaughterhouse Processing Machine

-

Advantage:

-

High Efficiecny

-

Feature:

-

Customized Slaughter Line

-

Capacity:

-

Customized

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sunton

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

customized

-

Weight:

-

3500 KG

-

Marketing Type:

-

Hot Product 2020

-

Name:

-

Poultry Processing Plant With Slaughter Equipment

-

Usage:

-

Chikken .goose .duck

-

Suit for:

-

Polury

-

Function:

-

Chicken Abattoir Equipment

-

Processing:

-

Complete Slaughter Line

-

Material:

-

Galvanized\stainless Steel

-

Object:

-

Slaughterhouse Processing Machine

-

Advantage:

-

High Efficiecny

-

Feature:

-

Customized Slaughter Line

-

Capacity:

-

Customized

Poultry Processing Plant With Slaughter Equipment

automatic slaughter machine use for poultry farm ,can suit for plucking the feather of turkey goose chicken duck rabbit ect

it can pluck feather paws skin dirty at one time

it can pluck feather paws skin dirty at one time

Product Description

Crate transfer washing

Crate washing conveyor is used to wash crates in a poultry processing plant.This equipment uses high pressure water to flush

dirtinside and outside crates,water inside machine cycles automatically to save water.Litters would be automatically excluded out

of from the equipment by the filter drum to ensure long-term stable and reliable using.

dirtinside and outside crates,water inside machine cycles automatically to save water.Litters would be automatically excluded out

of from the equipment by the filter drum to ensure long-term stable and reliable using.

High-frequency electric stunning machine

Our water stunner is designed to best ensure high stunning efficiency and chicken welfare at all line speeds. The electrical power

is connected between the earth rail and the electrical rail inside the tub. By achieving an optimal relationship between current,

voltage and resistance , the system induces immediate unconsciousness.

Slaughter line

Offers highly adjustable killing machines to ensure correct cutting and to best meet local market

preferences;double-sided,single-sided,or throat cut suitable for halhal slaughtering.

preferences;double-sided,single-sided,or throat cut suitable for halhal slaughtering.

Chicken platform line

Offers various slaughtering shackles to best fit the size of the birds being processed. An adequate shackle size limits leg

compression and ensures correct electrical contact during water stunning.

compression and ensures correct electrical contact during water stunning.

Scalding

In our Air Scalders, Birds are immersed in hot water while they are hanging in shackles suspended from the overhead conveyor. to

loosen the feathers before picking. Air is used to agitate the water in the scalding tank in order to create a downward turbulence

and keep birds immersed, and to facilitate the heat transfer to feather follicles.

loosen the feathers before picking. Air is used to agitate the water in the scalding tank in order to create a downward turbulence

and keep birds immersed, and to facilitate the heat transfer to feather follicles.

Pre-chilling

Our stainless steel water chillers are effective, reliable and built to last. The spiral design and the air agitation system

ensures an even chilling of birds.Manual re-shackling of birds to the overhead line after water chilling. Further down line, It is

possible to measure water pick-up and weight and classify the birds for further distribution.

ensures an even chilling of birds.Manual re-shackling of birds to the overhead line after water chilling. Further down line, It is

possible to measure water pick-up and weight and classify the birds for further distribution.

High performance evisceration

Faster line speed means higher production and greater profit opportunities. Today, offers evisceration equipment capable of processing up to 15000 birds per hour without jeopardising carcass quality nor food safety.

*Multiple adjustment features that enables processing varying bird flocks.

*Within the same machine set-up our machines can effectively process bird sizes that vary with+/- 350 grams.

*Adjustments can be performed during production to optimise uptime.

*correct adjustment ensures high yield and minimises faecal contamination.

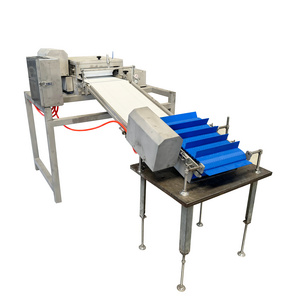

Cutting up

Portioning transfer line is used in poultry cutting-up procedure, it is made of stainless steel and nylon, accompanied with

variable frequency control,it strictly meets commodity inspection and food hygiene standards as well.

variable frequency control,it strictly meets commodity inspection and food hygiene standards as well.

Main Parameters:

1. High degree automation;

2. Labor saving;

3. High quality guarantee;

4. Low operation cost;

5. Long service life;

6. Easy operation and maintenance;

2. Labor saving;

3. High quality guarantee;

4. Low operation cost;

5. Long service life;

6. Easy operation and maintenance;

Welcome to check the below products

* Slaughter Equipment Chicken Electric Stun Machine for Poultry Slaughterhouse

* Chicken Spiral Precool Machine For Poultry Slaughterhouse

* Chicken Spiral Precool Machine For Poultry Slaughterhouse

* Pig Slaughter Equipment For Pig Slaughterhouse Line Abattoir Machine Turnkey Project

* Halal Cattle Slaughter Equipment For Cattle Abattoir Machine Turnkey Project Full Set

* Halal Slaughter Equipments For Sheep Goat Slaughterhouse Turnkey Project

Hot Searches