- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Shuangda

-

Voltage:

-

380V 50hz

-

Dimension(L*W*H):

-

3400*1060*1098

-

Power (kW):

-

25

-

Weight:

-

1098 KG

-

Automatic Grade:

-

Half Automatic

-

Raw material:

-

PVC PP PE Granules

-

Machine type:

-

Single Screw Extrusion Line

-

Keywords:

-

PVC Profile Extruder Line

-

Processing Type:

-

Exturding Machine

-

Color:

-

Customer Choice

-

Screw type:

-

Single-screw Screw

-

Product name:

-

Plastic Making Machine

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

80 rpm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Shuangda

-

Voltage:

-

380V 50hz

-

Dimension(L*W*H):

-

3400*1060*1098

-

Power (kW):

-

25

-

Weight:

-

1098 KG

-

Automatic Grade:

-

Half Automatic

-

Raw material:

-

PVC PP PE Granules

-

Machine type:

-

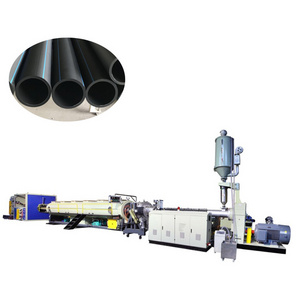

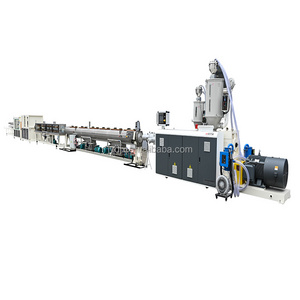

Single Screw Extrusion Line

-

Keywords:

-

PVC Profile Extruder Line

-

Processing Type:

-

Exturding Machine

-

Color:

-

Customer Choice

-

Screw type:

-

Single-screw Screw

-

Product name:

-

Plastic Making Machine

Products Description

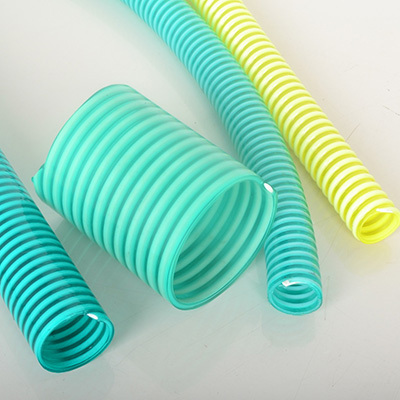

plastic soft pipe

The material of hose is PP, PVC, PE. There are also soft corrugated hose and reinforced hose.

According to material classification, plastic hose can be divided into single layer hose and multi-layer hose. Single layer hose includes metal hose and plastic extrusion hose; The multilayer hose includes aluminum-plastic composite hose, plastic composite hose and plastic coextrusion hose. According to the classification of processing technology, hose can be divided into seamless pipe and slotted pipe. Seamless tube includes cold stamping forming, rolling forming and extrusion forming; Slotted pipe includes high frequency welding, ultrasonic welding, thermal welding and other forming methods. Extrusion molding can process multi-layer or single-layer plastics.

Details Images

Use and characteristics

Use and characteristics

PVC plastic sealing strip production line, door and window sealing strip production line, the production line is composed of single screw extruder, mold, water tank, traction and winding machine, different molds make various shapes and sizes of PVC sealing products. These products are widely used in the production of plastic steel doors and windows, automobiles, containers, electric cars, refrigerators, disinfection cabinets and other sealing strip products

Overview:

Production line:

single screw extruder + mold + sink + traction +winder,

Mold type:

different mold do all kinds of shapes PVC sealing products

Application:

doors and windows, cars, containers, electric vehicles, refrigerators, sterilization cabinets and other sealing products.

Detailed introduction:

The plastic sealing strip production line must go through two processes in production, one process is granulation. Granulation requires a crusher, kneader, pelletizer and pelletizer.

Granulation process:

1. After mixing the auxiliary materials and PVC raw materials with the plastic kneader, put them into the feed port of the plastic granulator.

2. After the screw barrel is processed and plasticized, the pelletizer head is extruded into a strip,

3. Then wait for it to cool slightly, put the raw materials into the crusher for crushing,

4. Finally, through the pelletizer link for pelletizing production

Extrusion process (soft strip)

1. The plastic particles are directly put into the extruder for extrusion production,

2. Cooled directly after forming the mold,

3. Then it can be produced after pulling the strip. If the extruded sliver does not meet the size required by our 4. or the raw material formula is not mastered, you can directly reprocess the made sliver through the crushing link.

Extrusion process rigid strip

extrusion -cooling-traction-cutting

about cooling principe here is more detailed introduction

Sizing vacuum cooling table

our enginner:

hard material happened water easy deforming situation

1.cooling in Sizing mold in the water tank:

vacuum pump will exhausted inside air of molds, cooling the molds and Sizing the profile.

because inside molds will have a shape adhesive the profile and provide his support power, so will not happened deforming situation.

2. cooling in the water tank

inside of water the profile will lack the support power/mold wall, so there will have deforming machine.

Hot Searches