- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

231-072-3

-

Place of Origin:

-

Shenzhen, China

-

Brand Name:

-

JCX

-

Model Number:

-

JHX-318AB

-

Type:

-

Liquid Coating

-

Product name:

-

Epoxy Resin

-

Use:

-

Transportation, Construction, Woodworking

-

Material:

-

Liquid Epoxy Resin

-

Advantage:

-

High Gloss,No yellow,Crystal Clear, Low odor, Self Levelling

-

Shelf Life:

-

6 Months

-

Delivery Time:

-

10-20 Days

-

Mixing ratio:

-

A:B=3:1

Quick Details

-

CAS No.:

-

38891-59-7

-

Other Names:

-

Crystal epoxy resin

-

MF:

-

C15H16O2C2H7ONC3H5OCl

-

EINECS No.:

-

231-072-3

-

Place of Origin:

-

Shenzhen, China

-

Brand Name:

-

JCX

-

Model Number:

-

JHX-318AB

-

Type:

-

Liquid Coating

-

Product name:

-

Epoxy Resin

-

Use:

-

Transportation, Construction, Woodworking

-

Material:

-

Liquid Epoxy Resin

-

Advantage:

-

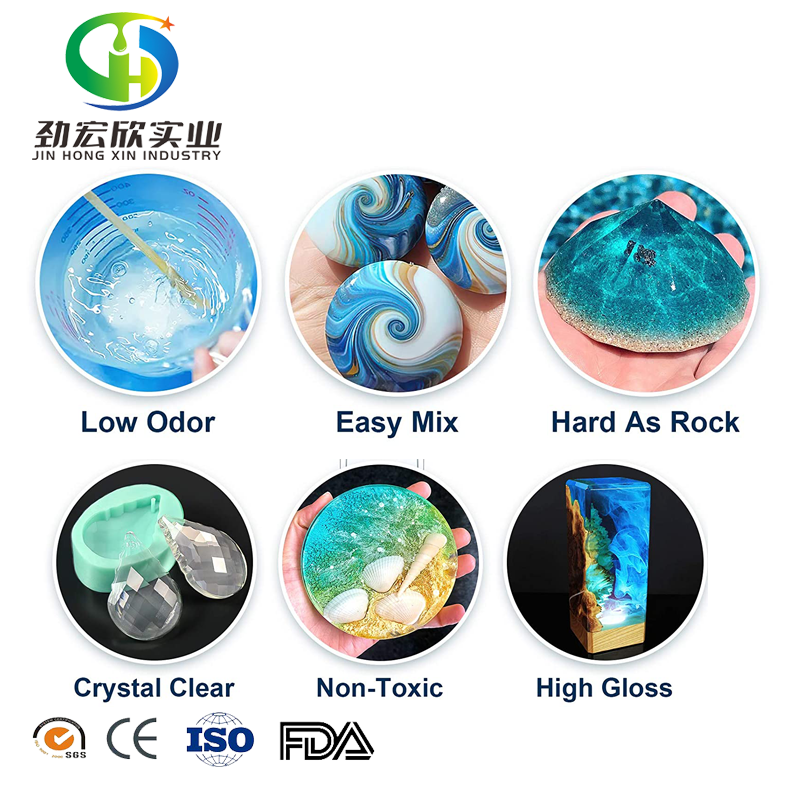

High Gloss,No yellow,Crystal Clear, Low odor, Self Levelling

-

Shelf Life:

-

6 Months

-

Delivery Time:

-

10-20 Days

-

Mixing ratio:

-

A:B=3:1

Product Description

| Name | Epoxy Resin |

| Material | Epoxy Resin and Hardener |

| Epoxy Resin and Hardener | Jewelry, DIY Artwork, Painting, Woodworking |

| Color | Transparent |

| Advantage | Great bonding capability, fast wet out, good flexibility, low odor |

| Delivery Time | 10-20 Days |

Technical parameter

| Resin 318A | Hardener 318B | |

| Color | Colorless&Translucent | Colorless&Clear |

| Density (g/m3) | 1.07+0.05 | 0.95+0.03 |

| Viscosity (mPa·s) | 1500+400 | 100max |

| Brookfield DV2TRV Test method | 25℃ | |

| Mixing ratio (by weight) | 3 : 1 | |

| (By volume) | 2.7 : 1 | |

After mixing

| Resin+Hardener | |

| Status | fluid |

| Viscosity | 250±50mPa.S |

| Brookfield DV2TRV Test method | 25℃ |

| Operating time (100g, 25℃) | 38±5 min |

| Brookfield DV2TRV Test method, viscosity up to 800mPa•s | |

| Dosage | 280-350 g/m2(Depending on the substrate) |

Curing time

| Initial curing | About 10-12 hours at room temperature |

| Final curing | 2 days at room temperature |

| Operating temperature range | 10℃-70℃ |

Instructions

Working environment

Please keep the plastic container clean. The components A and B are proportioned strictly according to the weight ratio, accurately weighed, and fully stirred clockwise along the inner wall of the container, and then allowed to stand for 3-5 minutes before use.

Precautions

Adjust the amount of glue according to the operating time and amount to avoid waste. When the temperature is lower than 15℃, please preheat the A glue to 30 ℃ before adjusting the glue, easy to operate (A glue will thicken when the temperature is low); The lid must be sealed after use to avoid product scrap due to moisture absorption. When the relative humidity is greater than 85%, the surface of the cured product will easily absorb the moisture in the air and form a layer of white mist. Therefore, when the relative humidity is greater than 85%, it is not suitable for room temperature curing. It is recommended to use heated curing.

Test Results

| Hardness | shoreD | 86 |

| Bending strength | Kg/mm2 | 28 |

| Heat distortion temperature | ℃ | 60 |

| Water absorption | % | <0.1 |

| Compressive strength | Kg/mm2 | 8.4 |

Storage

| Whether freezing | Yes | |

| Moisture sensitive | Resin | Hardener |

| No | Sensitive | |

| Recommended storage temperature | 15℃-25℃(Not lower than 10℃, not higher than 50℃) | |

| Valid period | 6 months from the original packaging | |

| Package | Resin | Hardener |

| 5 kg/pot | 5 kg/pot | |

Hot Searches