- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

132 rpm

-

Place of Origin:

-

Other Country

-

Brand Name:

-

yongxu

-

Voltage:

-

220/380v

-

Dimension(L*W*H):

-

34000*3800*3200

-

Weight:

-

30000 KG

-

Name:

-

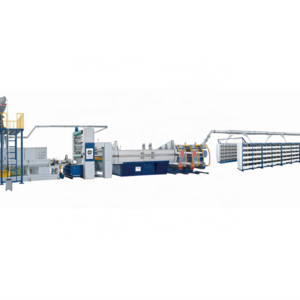

Extruder Machine Tape Line

-

Number of operators:

-

1 person

-

Product Type:

-

pp woven bag

-

width of tape:

-

1-4mm

-

output:

-

200 - 400 kg/h

-

thickness:

-

20-30mm

-

After-sales Service Provided:

-

Video technical support

-

After-sales Services Provided:

-

Online support

-

After Warranty Services:

-

Video technical support

-

After Warranty Service:

-

Online support

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

Other

-

Screw diameter (mm):

-

120 mm

-

Screw Speed (rpm):

-

132 rpm

-

Place of Origin:

-

Other Country

-

Brand Name:

-

yongxu

-

Voltage:

-

220/380v

-

Dimension(L*W*H):

-

34000*3800*3200

-

Weight:

-

30000 KG

-

Name:

-

Extruder Machine Tape Line

-

Number of operators:

-

1 person

-

Product Type:

-

pp woven bag

-

width of tape:

-

1-4mm

-

output:

-

200 - 400 kg/h

-

thickness:

-

20-30mm

-

After-sales Service Provided:

-

Video technical support

-

After-sales Services Provided:

-

Online support

-

After Warranty Services:

-

Video technical support

-

After Warranty Service:

-

Online support

Products Description

Application:

To produce PP/HDPE tape for woven bag, cement bag, mesh bag, sunshade net, tarpaulin, jumbo bag, geotextile, etc.

To produce PP/HDPE tape for woven bag, cement bag, mesh bag, sunshade net, tarpaulin, jumbo bag, geotextile, etc.

Main Technical Parameter

|

Model

|

YX-H1000

|

YX-H1200

|

YX-H1500

|

YX-H1600

|

|

Screw Dia.

|

90mm

|

105mm

|

120mm

|

130mm

|

|

Max. out put

|

350kg/h

|

500kg/h

|

600kg/h

|

650kg/h

|

|

Extruder Motor

|

100kw

|

110kw

|

132kw

|

132kw

|

|

T-Die length

|

1000mm

|

1200mm

|

1500mm

|

1600mm

|

|

Winder Number

|

168 spindles

|

192 spindles

|

240 spindles

|

288 spindles

|

|

Max. Winder Speed

|

520m/min.

|

520m/min.

|

520m/min.

|

520m/min.

|

|

Tape Denier

|

350D-2300D

|

350D-2300D

|

350D-2300D

|

350D-2300D

|

|

Size

|

33*3.5*3m

|

35*3.7*3m

|

37*4*3m

|

39*4*3m

|

Pingyang Yongxu Packaging CO.,LTD, Founded in 2010 at Xiaojiang Town, Wenzhou City, Zhejiang Province, China,

We are professional for complete line of PP Woven bag making machines such as Cement Woven Bag Making Machine, Rice Woven Bag Making

Machine, fertilizer Woven Bag Making Machine, Grain Woven Bag Making Machine, corn Woven Bag Making Machine, soybean Woven bag making machines, sesame Woven Bag Making Machine, Jumbo Woven Bag Making Machine, FIBC Woven Bag Making Machine, and Mesh Bag Making Machine, Leno Bag Making Machine, Plastic Rope Making Machine as well.We also make PP Woven bag Production Line such as Cement Woven Bag Production Line, Rice Woven Bag Production Line, fertilizer

Woven Bag Production Line, Grain Woven Bag Production Line, corn Woven Bag Production Line, soybean Woven bag Production Line,

sesame Woven Bag Production Line, Jumbo Woven Bag Production Line, FIBC Woven Bag Production Line, and Mesh Bag Production Line,

Leno Bag Production Line, Plastic Rope Production Line.

Machine, fertilizer Woven Bag Making Machine, Grain Woven Bag Making Machine, corn Woven Bag Making Machine, soybean Woven bag making machines, sesame Woven Bag Making Machine, Jumbo Woven Bag Making Machine, FIBC Woven Bag Making Machine, and Mesh Bag Making Machine, Leno Bag Making Machine, Plastic Rope Making Machine as well.We also make PP Woven bag Production Line such as Cement Woven Bag Production Line, Rice Woven Bag Production Line, fertilizer

Woven Bag Production Line, Grain Woven Bag Production Line, corn Woven Bag Production Line, soybean Woven bag Production Line,

sesame Woven Bag Production Line, Jumbo Woven Bag Production Line, FIBC Woven Bag Production Line, and Mesh Bag Production Line,

Leno Bag Production Line, Plastic Rope Production Line.

It is a specialized manufacturer of series of whole set plastic machinery products such as Complete Line of Woven Bag Making Machines, PP Mesh/Leno Bag/FIBC Woven Bag/Container Bag/Cement Bag/Rice Bag Making Machine,Plastic Bag Making Machine, Plastic Rope Making Machine. Having passed ISO9001:2000 International Quality System

authentification and got CE Certificate.

authentification and got CE Certificate.

Details Images

How to make pp woven sack

1. PP Raw Material 2. Wire Drawing 3. Testing

4. Weaving 5. PP Woven Roll 6. Printing

7. Lamination 8.Cutting And Sewing 9. Packing

Certifications

Exhibition

Packing

Work shop

Contact Us

|

Company Name

|

Pingyang Yongxu Packaging Co., Ltd.

|

|

Contact Person

|

Vera Liu

|

|

Mobile

|

+8613758816220

|

|

Whatsapp

|

+8613758816220

|

|

Wechat

|

+8613758816220

|

|

Email

|

shirley@hqxzusa.com

|

Hot Searches