- Product Details

- {{item.text}}

Quick Details

-

Surface Roughness(μm):

-

0.32

-

Grinding Length(mm):

-

750

-

Max. Weight of Workpiece(kg):

-

50

-

Center Height (mm):

-

135

-

Wheel Size(mm):

-

400*50*203

-

Wheel Speed (rpm):

-

400

-

Table Travel (X) (mm):

-

630

-

Table Travel (Y) (mm):

-

250

-

Roundness(mm):

-

0.002

-

Cylindricity (mm):

-

0.005

-

Year:

-

new date

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MATSUMOTO

-

Voltage:

-

380/415V

-

Dimension(L*W*H):

-

2850*21500*2200mm

-

Weight (KG):

-

3950

-

Power (kW):

-

5.5

-

Cylindrical grinding machine:

-

MK1420

-

External grinding diameters:

-

6-200mm

-

Max. length to be ground:

-

500/750/1000/1500mm

-

Center Height:

-

135mm

-

Max. weight of workpiece:

-

100kg

-

Center taper(MT):

-

4

-

Max grinding wheel(OD*W*ID):

-

400*50*203 mm

-

Grinding wheel speed:

-

35r/min

-

Headstock spindle speed:

-

20-400r/min

-

Workhead motor power:

-

1.5Kw

Quick Details

-

Grinding Diameter(Outer)(mm):

-

200

-

Grinding Diameter(Inner)(mm):

-

8

-

Max. Length of Workpiece (mm):

-

500

-

Surface Roughness(μm):

-

0.32

-

Grinding Length(mm):

-

750

-

Max. Weight of Workpiece(kg):

-

50

-

Center Height (mm):

-

135

-

Wheel Size(mm):

-

400*50*203

-

Wheel Speed (rpm):

-

400

-

Table Travel (X) (mm):

-

630

-

Table Travel (Y) (mm):

-

250

-

Roundness(mm):

-

0.002

-

Cylindricity (mm):

-

0.005

-

Year:

-

new date

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

MATSUMOTO

-

Voltage:

-

380/415V

-

Dimension(L*W*H):

-

2850*21500*2200mm

-

Weight (KG):

-

3950

-

Power (kW):

-

5.5

-

Cylindrical grinding machine:

-

MK1420

-

External grinding diameters:

-

6-200mm

-

Max. length to be ground:

-

500/750/1000/1500mm

-

Center Height:

-

135mm

-

Max. weight of workpiece:

-

100kg

-

Center taper(MT):

-

4

-

Max grinding wheel(OD*W*ID):

-

400*50*203 mm

-

Grinding wheel speed:

-

35r/min

-

Headstock spindle speed:

-

20-400r/min

-

Workhead motor power:

-

1.5Kw

Products Description

Product Paramenters

Application:

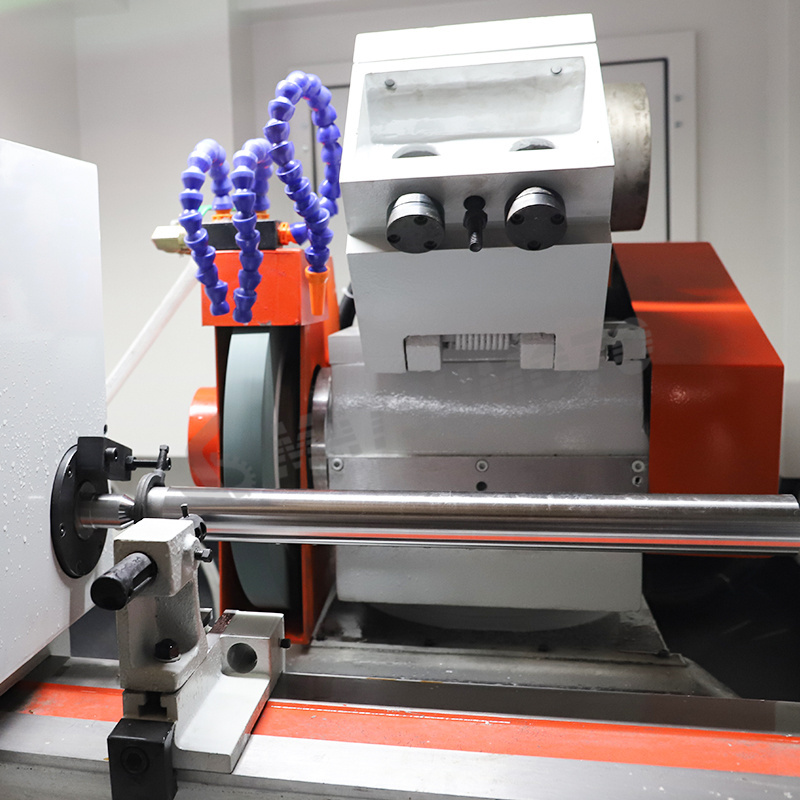

1.The spindle of the grinding wheel adopts the large taper four-oil wedge bearing to automatically adjust the gap dynamic pressure, which has higher rigidity and precision of the grinding wheel.

2.Table (Z axis) drive and horizontal feed (X axis) drive drive adopts THK ball screw servo direct drive

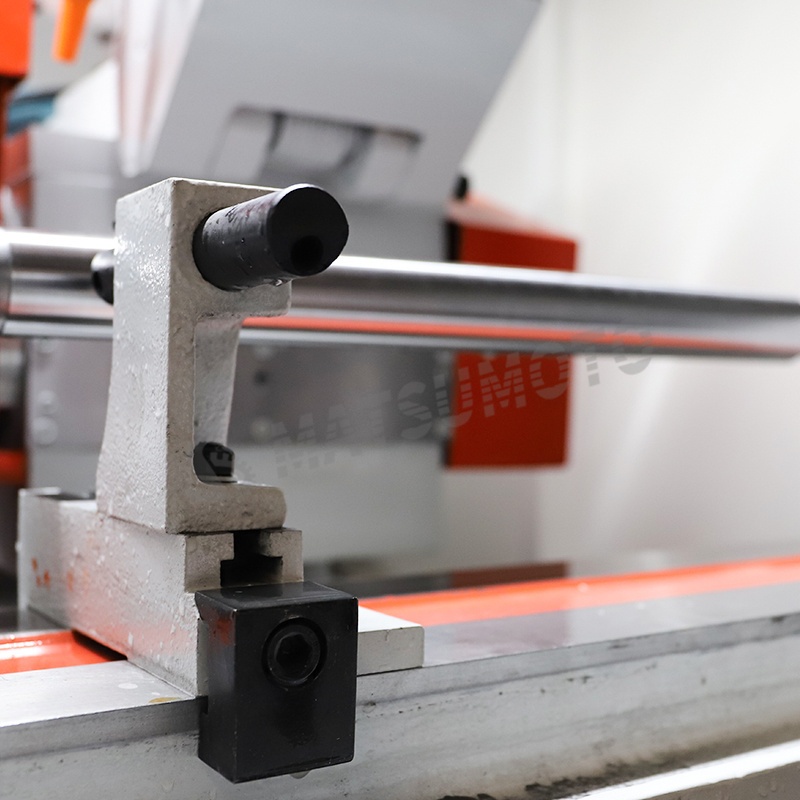

structure,Table(z-axis)guide rail adopts open unloading hydrostatic guide rail structure, good rigidity, motion balance, low friction coefficient, lowspeed and no creep.The transverse-feed (X-axis) guide rail adopts Swiss linear guide rail and applies pre-tightening forceto meet the requirements of high rigidity, low friction, no clearance and good dynamic response for precision grinding.The workhead adopts static spindle top grinding structure with good rigidity, suitable for precision grinding.

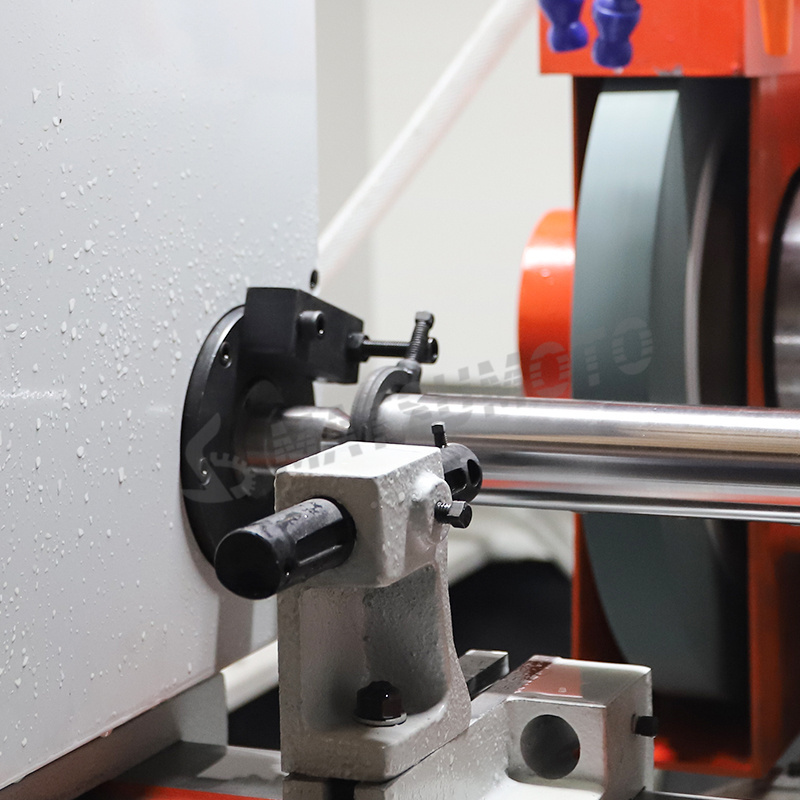

3.Tailstock sleeve adopts linear bearing structure, no gap feeding, good rigidity, and can realize hydraulic braking and manual dual mode control.

4.The bed adopts double-layer structure (finite element analysis), special ratio cast iron casting, manual scraping and grinding of guide rail surface, good dynamic/static rigidity, stable thermal deformation.

Product main technical parameters:

1.The spindle of the grinding wheel adopts the large taper four-oil wedge bearing to automatically adjust the gap dynamic pressure, which has higher rigidity and precision of the grinding wheel.

2.Table (Z axis) drive and horizontal feed (X axis) drive drive adopts THK ball screw servo direct drive

structure,Table(z-axis)guide rail adopts open unloading hydrostatic guide rail structure, good rigidity, motion balance, low friction coefficient, lowspeed and no creep.The transverse-feed (X-axis) guide rail adopts Swiss linear guide rail and applies pre-tightening forceto meet the requirements of high rigidity, low friction, no clearance and good dynamic response for precision grinding.The workhead adopts static spindle top grinding structure with good rigidity, suitable for precision grinding.

3.Tailstock sleeve adopts linear bearing structure, no gap feeding, good rigidity, and can realize hydraulic braking and manual dual mode control.

4.The bed adopts double-layer structure (finite element analysis), special ratio cast iron casting, manual scraping and grinding of guide rail surface, good dynamic/static rigidity, stable thermal deformation.

Product main technical parameters:

|

Model

|

MK1420-750

|

|

Max. O.D. to be ground

|

φ6-200mm

|

|

Max. I.D. to be ground

|

Φ10-100mm

|

|

Max. length to be ground

|

5-750mm

|

|

Center Height

|

135mm

|

|

Max. weight of workpiece

|

50KG

|

|

Center taper(MT)

|

4

|

|

Rotation Angle of upper table

|

0-5°/0-9°

|

|

Max grinding wheel(OD*W*ID)

|

400*50*203 mm

|

|

Grinding wheel speed

|

35r/min

|

|

Grinding wheel motor power

|

5.5Kw

|

|

Headstock spindle speed

|

20-400r/min

|

|

Workhead motor power

|

1.5Kw

|

|

Spindle speed/stepless

|

50hz:25-260 r/min

|

|

Max. stroke of the table (Z axis) axis

|

630mm

|

|

Workbench (Z-axis) maximum speed

|

5m/min

|

|

Workbench (Z, axis) resolution

|

0.001mm

|

|

Positioning accuracy of workbench (Z-axis)

|

0.008mm

|

|

Repositioning accuracy of workbench (Z-axis)

|

0.004mm

|

|

Table (Z-axis) servo-motor power

|

2.2kw

|

|

Grind wheel frame (X-axis) max. stroke

|

250mm

|

|

Grind wheel frame (X-axis) max. speed

|

5m/min

|

|

Grind wheel frame (X-axis) resolution ratio

|

0.001mm

|

|

Grind wheel frame (X-axis) positioning accuracy

|

0.006mm

|

|

Grind wheel frame (X-axis) repositioning accuracy

|

0.003mm

|

|

Grind wheel frame (X axis) motor power

|

1.5kw

|

|

Guide rail lubrication

|

0.1mpa

|

|

Work system

|

0.8-1mpa

|

|

Cooling pump flow

|

50L/min

|

|

Cooling motor

|

AB-50

|

|

Machine weight

|

3950kg

|

|

Overall dimensions

|

2850*2150*2250mm

|

Details Images

Recommend Products

Hot Searches