Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

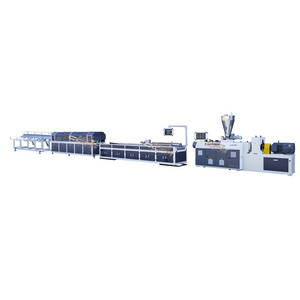

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Bonzer

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

2200X800X1700MM

-

Power (kW):

-

80

-

Weight:

-

5000 KG

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

Unapplicable

-

Screw Speed (rpm):

-

45 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Bonzer

-

Voltage:

-

380V/220V/440V

-

Dimension(L*W*H):

-

2200X800X1700MM

-

Power (kW):

-

80

-

Weight:

-

5000 KG

Hot Searches