- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2000

-

Voltage:

-

380V/220V

-

Current:

-

120a

-

Rated Capacity:

-

1kw 2kw 3kw 5kw

-

Rated Duty Cycle:

-

3 6 12 15

-

Dimensions:

-

1500mm*800mm

-

Use:

-

welding metal

-

Product name:

-

welding robot

-

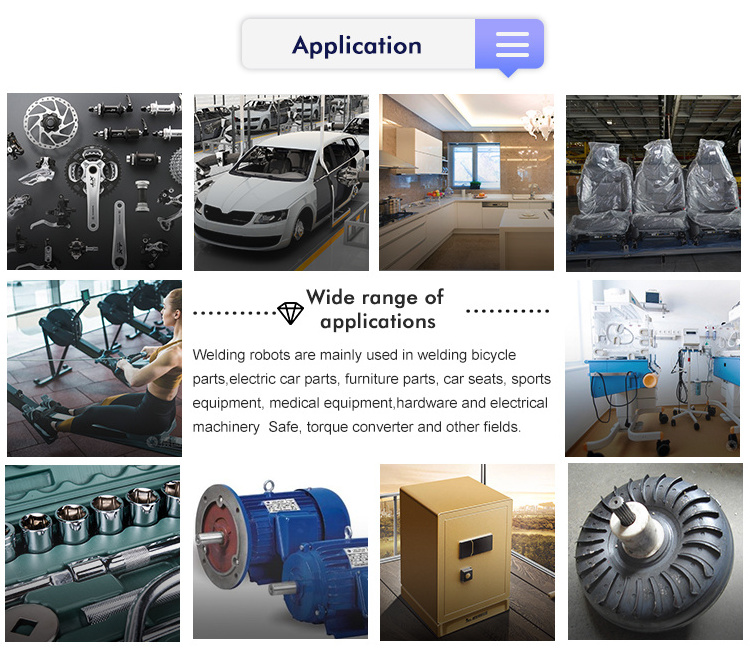

Application:

-

welding metal

-

Function:

-

production metal products

-

Welding mode:

-

TIG MIG MAG SAW PAW

-

Advantage:

-

Cost Save high efficiency

-

Color:

-

Customer Requirement

-

Power supply:

-

380/3 /50Hz

-

Feature:

-

High Efficiency Automatic Welding Robot

-

Welding Speed:

-

450-600mm/min

-

Accessories:

-

Welding Cable

Quick Details

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AMH

-

Weight (KG):

-

2000

-

Voltage:

-

380V/220V

-

Current:

-

120a

-

Rated Capacity:

-

1kw 2kw 3kw 5kw

-

Rated Duty Cycle:

-

3 6 12 15

-

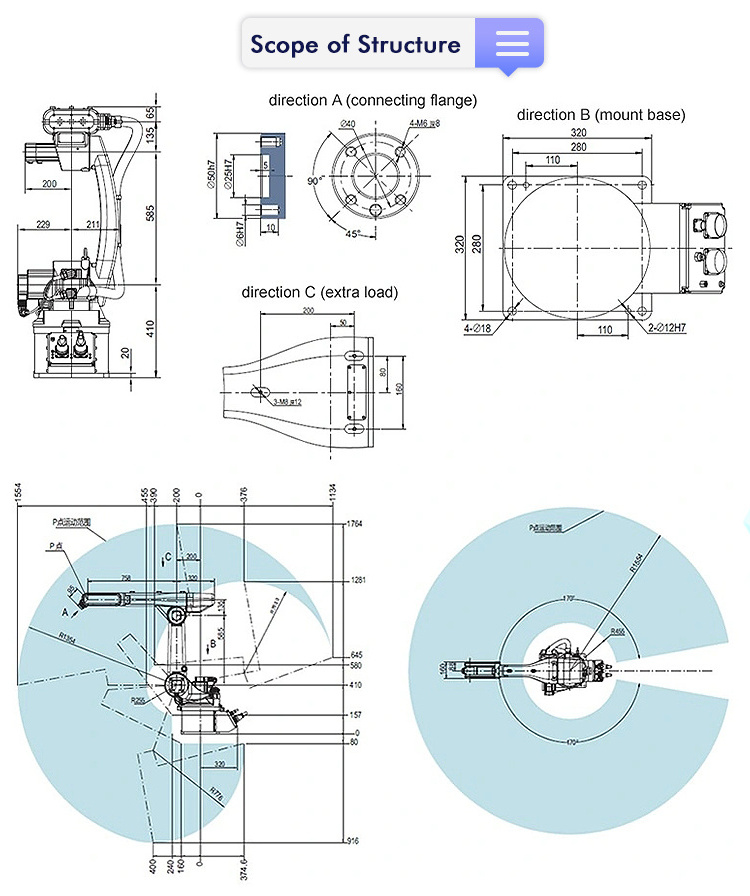

Dimensions:

-

1500mm*800mm

-

Use:

-

welding metal

-

Product name:

-

welding robot

-

Application:

-

welding metal

-

Function:

-

production metal products

-

Welding mode:

-

TIG MIG MAG SAW PAW

-

Advantage:

-

Cost Save high efficiency

-

Color:

-

Customer Requirement

-

Power supply:

-

380/3 /50Hz

-

Feature:

-

High Efficiency Automatic Welding Robot

-

Welding Speed:

-

450-600mm/min

-

Accessories:

-

Welding Cable

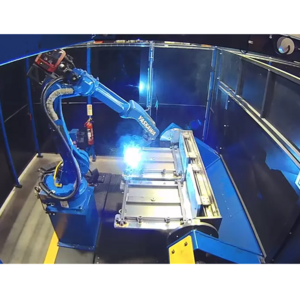

Arc welding utilizes an electric arc between an electrode and a metal base using either consumable or non-consumable electrodes. An arc welding robot uses a process which applies intense heat to metal at a joint, causing the metal to melt and intermix.

Welding robot arm advantages

stable welding quality, to ensure a high degree of uniformity of the product.

Using application robots to automate production lines is an easy way to save time and money.

Industrial robots also reduce waste and produce high-quality products with continuous precision.

Robots can also save workers from health hazards by limiting exposure to fumes and decreasing risk of arc burn.

24 hours can be continuously produced, the maximum increase in productivity.