Henan Bolben Boiler Co., Ltd. has been committed to the manufacturing and research and development of industrial boilers since its establishment. At present, the company has held A class A boiler manufacturing license, American ASME standard "S" (power boiler), "U" (pressure vessel) license seal and other international certifications, is the leader of industrial boiler manufacturers. The high-quality products produced by Bolben boiler sell well at home and abroad, covering all industries such as food, paper, electronics, heating and so on.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

borben

-

Dimension(L*W*H):

-

5400*2200*2400

-

Weight:

-

2.5t

-

Design fuel:

-

Biomass Pellet

Quick Details

-

Core Components:

-

Boiler main body

-

Steam Production:

-

Max.20th

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

borben

-

Dimension(L*W*H):

-

5400*2200*2400

-

Weight:

-

2.5t

-

Design fuel:

-

Biomass Pellet

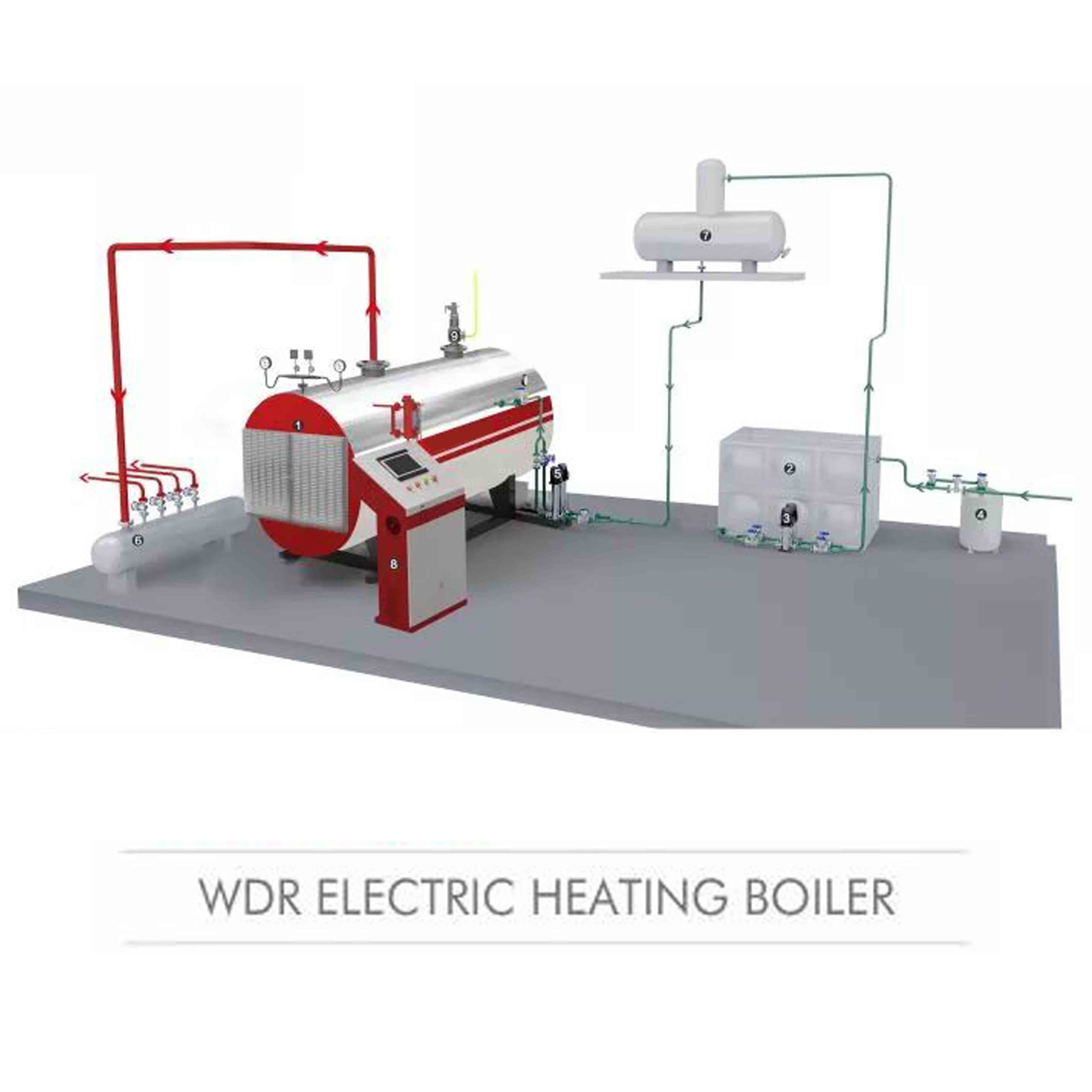

Product display

The boiler body adopts high quality thermal insulation materials to do heat preservation, small heat dissipation, reduce energy consumption, the perfect combination of the furnace body and the electronic control device, to achieve mechanical and electrical integration, reduce the occupation of space, the electric heat pipe and the furnace body through the flange connection, convenient disassembly, maintenance is also very convenient. With automatic fault memory function, easy to view and maintain. The controller adopts digital liquid crystal display and graphical operation interface, through which the user can directly view the operation parameters of the equipment. The boiler adopts step-by-step loading or load reduction design, effectively protecting the heating element, reducing the impact on the power grid and extending the service life. The heating device adopts ceramic electric heat pipe, whose surface load is several times lower than that of the metal heating tube. Prolong service life and improve thermal efficiency by 99%. The automatic operation cycle of the boiler can be set according to the needs, and the best is that multiple different working cycles can be set within a day

Product introduction

Type parameter

|

Type specification

|

Rated evaporation capacity

|

Rated working pressure

|

Saturated steam temperature

|

Boiler thermal efficiency

|

Rated power

|

Design fuel

|

Maximum shipping weight

|

Maximum transport size

|

|

Unit

|

(T/h)

|

(Mpa)

|

(℃)

|

(%)

|

(KW)

|

|

(KG)

|

(MM)

|

|

WDR0.3-0.7

|

0.3

|

|

|

|

216

|

|

950

|

2200*1300*1400

|

|

WDR0.5-0.7

|

0.5

|

|

|

|

360

|

|

1500

|

2400*1400*1600

|

|

WDR0.7-0.7

|

0.7

|

|

|

|

504

|

|

1700

|

2500*1500*1600

|

|

WDR1.0-0.7

|

1

|

0.7

|

171

|

|

720

|

|

1850

|

2600*1500*1900

|

|

WDR1.0-1.0

|

1

|

1.0

|

184

|

|

720

|

|

1850

|

2600*1500*1900

|

|

WDR2.0-0.7

|

2

|

1.25

|

194

|

≥98

|

1440

|

Electric energy

|

3000

|

3100*1700*2300

|

|

WDR2.0-1.0

|

2

|

1.6

|

205

|

|

1440

|

|

3000

|

3100*1700*2300

|

|

WDR2.0-1.25

|

2

|

2.5

|

225

|

|

1440

|

|

3100

|

3100*1700*2300

|

|

WDR2.0-1.6

|

2

|

|

|

|

1500

|

|

3250

|

3100*1700*2300

|

|

WDR2.0-2.5

|

2

|

|

|

|

1500

|

|

3360

|

3100*1700*2300

|

|

WDR4.0-1.25

|

4

|

|

|

|

2880

|

|

6800

|

4200*2000*2300

|

Scope of application

Hot Searches