- Product Details

- {{item.text}}

Quick Details

-

X,Y,Z Traveling Positioning Accuracy:

-

±0.01/1800mm

-

X,Y,Z Repositioning Accuracy::

-

±0.01mm

-

Table Surface:

-

T-slot table (Vacuum and T-slot option)

-

Z Structure:

-

Hiwin Rail Linear Bearings and Ball Screw

-

Max. Power Consumption:

-

(Without Spindle) 4 Kw

-

Max. Rapid Travel Rate:

-

40000mm/min

-

Max. Working Speed:

-

30000mm/min

-

Spindle Power:

-

9KW

-

Weight:

-

6000kgs

-

Power:

-

10kw

Quick Details

-

Certification:

-

ce

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas

-

Product name:

-

wooden foam moulding machines

-

X,Y,Z Traveling Positioning Accuracy:

-

±0.01/1800mm

-

X,Y,Z Repositioning Accuracy::

-

±0.01mm

-

Table Surface:

-

T-slot table (Vacuum and T-slot option)

-

Z Structure:

-

Hiwin Rail Linear Bearings and Ball Screw

-

Max. Power Consumption:

-

(Without Spindle) 4 Kw

-

Max. Rapid Travel Rate:

-

40000mm/min

-

Max. Working Speed:

-

30000mm/min

-

Spindle Power:

-

9KW

-

Weight:

-

6000kgs

-

Power:

-

10kw

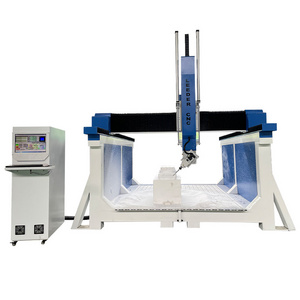

4 axis mold processing CNC Center for 3d model car fiberglass boat milling machine

Applicable Industry

1. Mold industries: sculpture various large non-metallic mold can be particularly suitable for any kind of Foam (EPS) mold, wooden ship model, wooden model aviation and other wooden mold.

2.Foam industry: Can carve and cut on any kind of Foam (EPS) , do 2D and 3D dimension processing.

3. Three dimension: with 4 axis, Big diameter Rotary, can do any kind of 3D cylinder material and mold processing for advertisement industry , cloth and shoes industry

It can manufacture the following effects: engraving, cutting, milling ,drilling, relief, shadow, encasement and so on.

Product description

1. The whole bed and frame are made of large square tube structure, welded by scientific method, tempered, and distracted.

2. The three axes use high-precision square guide rails, wherein the Z-axis adopts four rows of guide rail structure, no jitter, higher precision; Z-axis is ball screw drive, XY is rack drive mode (Taiwan original helical gear)

3. Adopt 9kw HSD or HQD aircooling spindle

4. The motor and the drive both use the servo system for higher stability.

5. The system adopts Taiwan Syntec control system, man-machine interface operation

6. The whole machine adopts dustproof design; the guide rail and the screw are automatic lubrication system.

7. Optional vacuum suction cup, cast iron platform, tool magazine

Technical Parameter

|

1 |

X,Y,Z Working Area |

1800x3000x1000mm /2000*4000*1000mm or as customized |

|

2 |

Table Size |

2800*3500*2300mm /3000*4500*2300mm or as customized |

|

3 |

X,Y,Z Traveling Positioning Accuracy |

±0.01/1800mm |

|

4 |

X,Y,Z Repositioning Accuracy: |

±0.01mm |

|

5 |

Table Surface |

T-slot table (Vacuum and T-slot option) |

|

6 |

Frame |

Big Steel Tube Structure |

|

7 |

X, Y Structure |

Rack and Pinion Drive, Hiwin Rail Linear Bearings |

|

8 |

Z Structure |

Hiwin Rail Linear Bearings and Ball Screw |

|

9 |

Max. Power Consumption |

(Without Spindle) 4 Kw |

|

10 |

Max. Rapid Travel Rate |

40000mm/min |

|

11 |

Max. Working Speed |

30000mm/min |

|

12 |

Spindle Power |

9KW |

|

13 |

Spindle Speed |

0-18000RPM |

|

14 |

Drive Motors |

850W /1300W Yaskawa Motors |

|

15 |

Working Voltage |

AC380V/50/60Hz,3PH (Option: 220V)) |

|

16 |

Command Language |

G Code |

|

17 |

Operating System |

Syntec Control System |

|

18 |

Computer Interface |

USB |

|

19 |

Flash Memory |

512M |

|

20 |

Collet |

ER32 |

|

21 |

X,Y Resolution |

<0.01mm |

|

22 |

Software Compatibility |

Type3/Ucancam/ powermill/UG |

|

23 |

Running Environment Temperature |

0 - 45 Centigrade |

|

24 |

Relative Humidity |

30% - 75% |

|

25 |

Packing Size |

3500X2100X2300mm |

|

26 |

N.W. |

6000KG |

|

27 |

G.W. |

6500KG |

|

28 |

Optional Parts |

Dust Collector |

|

Vacuum Pump |

||

|

Rotary System |

||

|

Mist-cooling System |

||

|

Delta/ Panasonic Servo Motors |