DYVAC use double layer of stainless steel 304 to manufacture the vacuum chamber , with advanced welding technology and ensure the

air tightness of the chamber . better vacuum pressure protection capability ,higher ultimate vacuum , More durable service life.

and built in high power heater and ensure the temperature inside the chamber .

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DYVAC

-

Voltage:

-

380V or customized

-

Power:

-

Custom Made

-

Dimension(L*W*H):

-

Custom Made

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers Service Machinery Overseas

-

Technology:

-

Multi Arc + Sputtering

-

Advantage:

-

High Efficiency Low Cost

-

Chamber Material:

-

Stainless Steel 304

-

paint colo:

-

Gold, Rose Gold, Blue, Gray, Black, Rainbow

-

controlling system:

-

PLC Touch Screen

-

business type:

-

manufacturer/supplier

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

pump system orign:

-

basis on your request

-

product:

-

Magnetron sputtering vacuum coating Machine

Quick Details

-

Machine Type:

-

Coating Equipment,PVD vacuum coating machine, Coating Equipment

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DYVAC

-

Voltage:

-

380V or customized

-

Power:

-

Custom Made

-

Dimension(L*W*H):

-

Custom Made

-

Weight (KG):

-

5000

-

After-sales Service Provided:

-

Engineers Service Machinery Overseas

-

Technology:

-

Multi Arc + Sputtering

-

Advantage:

-

High Efficiency Low Cost

-

Chamber Material:

-

Stainless Steel 304

-

paint colo:

-

Gold, Rose Gold, Blue, Gray, Black, Rainbow

-

controlling system:

-

PLC Touch Screen

-

business type:

-

manufacturer/supplier

-

After Warranty Service:

-

Video technical support, Online support, Spare parts

-

pump system orign:

-

basis on your request

-

product:

-

Magnetron sputtering vacuum coating Machine

Product Description

|

DY Multi Arc Ion vacuum coating machine model and technical parameter

(hardware, ceramic, cutlery etc ) |

|

|

|

|

|

|

||||||

|

model

|

DY-700

|

DY -900

|

DY -1000

|

DY -1250

|

DY -1400

|

DY -1600

|

||||||

|

Chamber size(mm)

|

Ф700×H900

|

Ф900×H1100

|

Ф1000×H1200

|

Ф1250×H1350

|

Ф1400×H1600

|

Ф1600×H1800

|

||||||

|

Power type

|

Arc power, filament power, pulse bias power

|

|

|

|

|

|

||||||

|

Vacuum chamber structure

|

Vertical front door structure, postposition sucking gas system, double layer water cooling chamber

|

|

|

|

|

|

||||||

|

Vacuum chamber material

|

High quality stainless steel chamber

|

|

|

|

|

|

||||||

|

Ultimate vacuum

|

6.0×10-4Pa

|

|

|

|

|

|

||||||

|

Pumping time

(no load)

|

pumping from atmosphere to 8.0×10-3Pa≤15per minutes

|

|

|

|

|

|

||||||

|

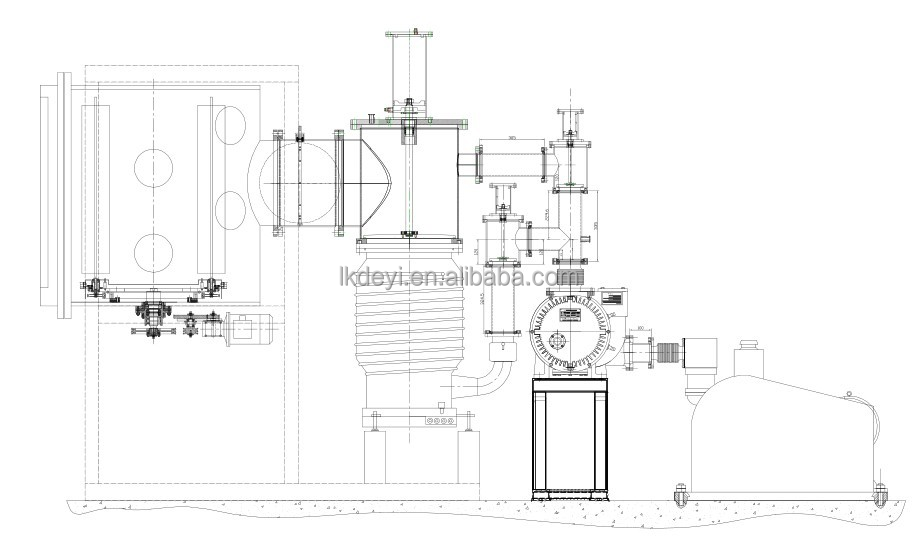

Vacuum pumping system |

Diffusion or molecular pump+ Roots pump+ mechanical pump+ holding pump

(The detailed model need to collocate according to customer need)

|

|

|

|

|

|

||||||

|

Arc power

|

4 sets or 6 sets

|

6 sets or 8 sets

|

8 sets or 10 sets

|

10 sets or 12 sets

|

14 sets or 16 sets

|

16 sets or 18 sets

|

||||||

|

Bias power

|

10KW/set

|

20KW/set

|

20KW/set

|

30KW/set

|

40KW/set

|

50KW/set

|

||||||

|

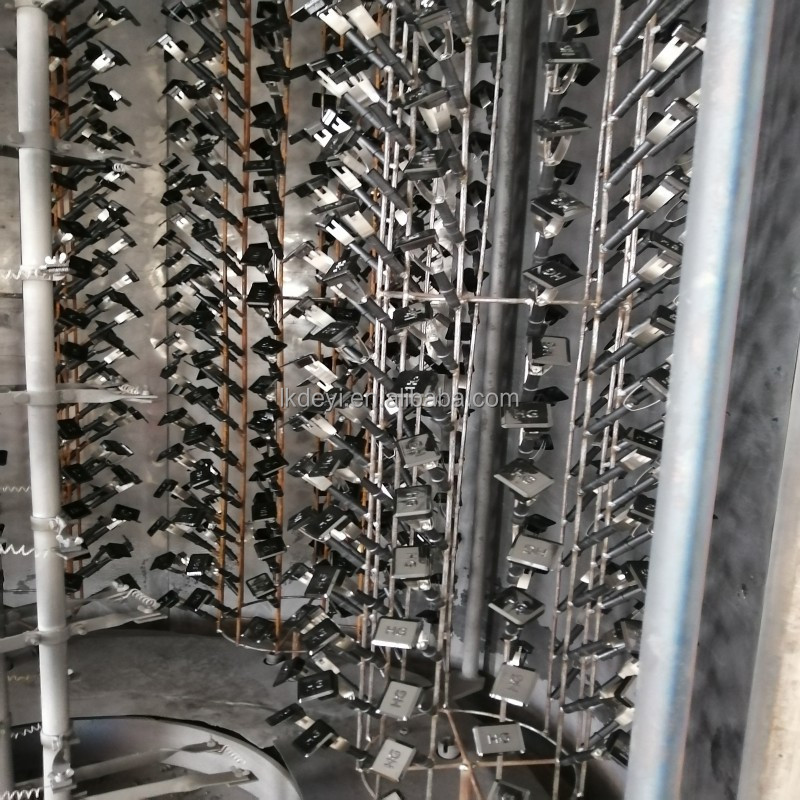

Workpiece rotating method

|

Planetary revolution and rotation, inverter control(controlled and adjustable)

|

|

|

|

|

|

||||||

Our Advantage

Double layer Vacuum Chamber

Excellent vacuum pumping system

DYVAC choose the famous Chinese brand pump for the vacuum pumping system . its Vacuum is fast and steady .to obtain high

efficiency coating cycle time , greatly reduces the vibration frequency and energy consumption of the equipment . We can offer the import brand pump service if the customer required .Such Leybold ,Osaka, Shimadzu ,Pfeiffer etc .

efficiency coating cycle time , greatly reduces the vibration frequency and energy consumption of the equipment . We can offer the import brand pump service if the customer required .Such Leybold ,Osaka, Shimadzu ,Pfeiffer etc .

Control System and Famous Electrical Production

Delta DVP series PLC programmable industrial controller, the whole machine automatic monitoring, protection, control, coating.

With manual, semi-automatic, fully automatic functions

With manual, semi-automatic, fully automatic functions

DYVAC’s 10th Arc Source and the Parts

Equipped with DYVAC’s 10th generation high-performance arc power supply and cathode arc source device , it means more uniform coating film , leading reliable performance of continuous coating DYVAC keep the technology R&D , so the technology are

progressing .

progressing .

Finished Product Photo

Company information

DEYI Vacuum coating machine closely tracks the development of international vacuum technology, with advanced design concept and rapid development and application of new technologies,ensuring high-tech and high-level products of the company。

It is widely used in industrial products, civilian daily necessities, precision optics, solar photovoltaic, display, semiconductor, power devices, tools and dies, aviation, ships, vehicle batteries, lighting, interior and exterior decoration, smart phones, 3C electronic products, hardware watches, plastics, ceramics, glass and other industries。

Packing & Delivery

FAQ

Q1. How about the quality control about your products?

We have the ISO9001 QMS , CE certification. All machine will past the internal quality test and field testing.

Q2. Does your company provide after-sale service ?

Yes. We have the field engineer to set-up and debug the machine . After the machine is fully running . we have one year of quality warranty and full-life maintenance service .

Q3. Can you provide technical support about my work-flow?

Yes . The Tongyi have more than 20 years of experience in vacuum coating territory. We also have an independent R&D department ,which will solve your production issue.

Q4. Do you provide the second-hand machine ?

No. All machine in Tongyi are new . We don't manufacture the second-hand machine .

Q5. Does your company supply accessories for our spare parts after we bought your products ?

Yes . We can supply you all the accessories especially for some consumable material .

Hot Searches