- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DEPAI

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

2800*950*1400mm

-

Weight:

-

1800 kg

-

PLC Brand:

-

None

-

Product name:

-

sticker printing labels roll to roll die cutting machine

-

Application:

-

label cutting

-

After-sales Service Provided:

-

Online Support

-

Machine type:

-

Automatic

-

Keyword:

-

flat bed die cutting machine and die cutter

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

120 m/min

-

Max. workable width:

-

320

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DEPAI

-

Voltage:

-

380V/220V

-

Dimension(L*W*H):

-

2800*950*1400mm

-

Weight:

-

1800 kg

-

PLC Brand:

-

None

-

Product name:

-

sticker printing labels roll to roll die cutting machine

-

Application:

-

label cutting

-

After-sales Service Provided:

-

Online Support

-

Machine type:

-

Automatic

-

Keyword:

-

flat bed die cutting machine and die cutter

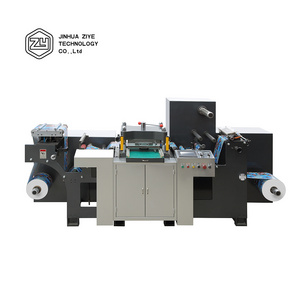

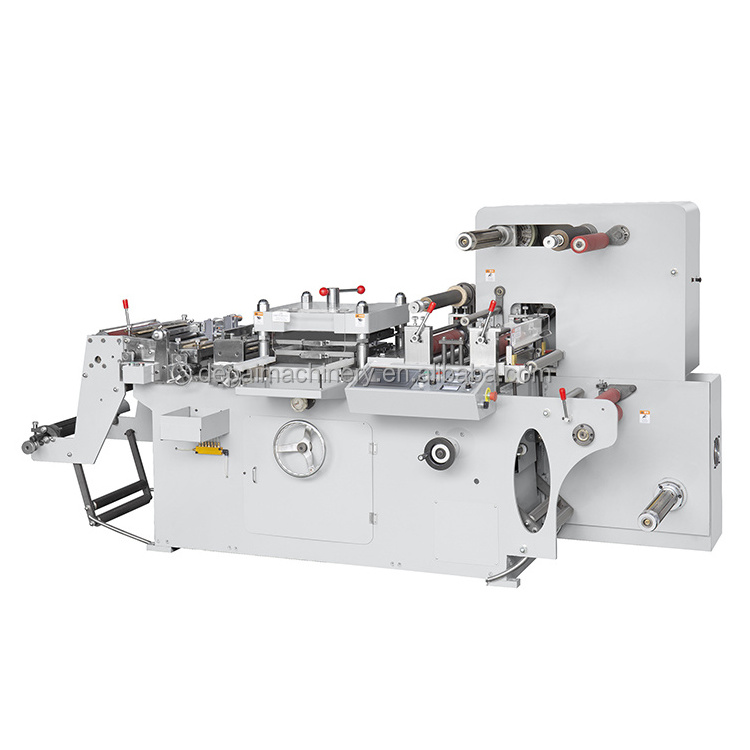

China low price popular Automatic flat bed sticker printing labels roll to roll die cutting machine

Product Overview

Description

This machine is applicable to die cut through platen with high precision,while the computer controls the slices and conveyor.The sides of trademarks and longitudinal route are tracked through three photoelectric eyes to position,while the die cutting,discarded delivery or auto trademark labeling can be finished in the processing of one web.

The machine is applicable to die cut paper self adhesive trademark, Dacron film trademark and laser anti-false trademark.It is an ideal complete set of flexo printing machine,continuous thread printing machine,gravure printing machine and die compress machine for anti-false trademarks.

The machine is applicable to die cut paper self adhesive trademark, Dacron film trademark and laser anti-false trademark.It is an ideal complete set of flexo printing machine,continuous thread printing machine,gravure printing machine and die compress machine for anti-false trademarks.

Standard Configuration:

1. One Die Cutting Station.

One Sheet Cutting Station

2. With 1pc 3’’ Unwinding Shaft, 1pc 3” Rewinding Shaft

3. With Meter/Number counter.

4. With Two Photoelectric Eyes---Web Guide System

5. 1pc Color Track Photocell Sensor

6. PLC, Touch Screen...Controller

Optional configuration:

1. Hot stamping unit

2. Punching unit

3. Lamination unit

4.Slitting Unit

1. Hot stamping unit

2. Punching unit

3. Lamination unit

4.Slitting Unit

PRODUCT SPECIFICATIONS

|

Model

|

DP-FD320B

|

DP-FD350B

|

|

Cutting Speed

|

300times/min

|

350times/min

|

|

Max Dia Of Unwinding

|

600mm

|

600mm

|

|

Max Web Width

|

320mm

|

350mm

|

|

Max Cutting Width

|

300mm

|

300mm

|

|

Max Cutting Length

|

300mm

|

300mm

|

|

Precision

|

±0.1mm

|

±0.1mm

|

|

Main motor

|

2.2kw

|

3kw

|

|

Total power

|

3.5kw

|

6kw

|

|

Voltage

|

220V±10%

|

380V±10%

|

|

Weight

|

about 1800kg

|

about 1800kgs

|

|

Size

|

2800*950*1400mm

|

2900*950*1400mm

|

Standard Configuration

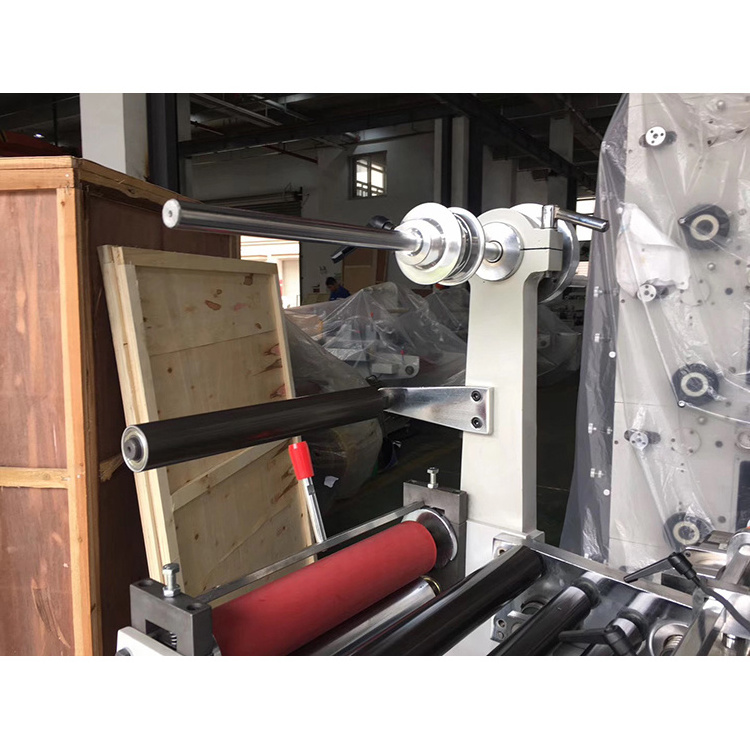

Winding / Rewinding Air Shaft

With 3" air expanding shafts,max rewinding /unwinding diameter is 500mm for big roll

Die Cutting Station

Max die cutting width 300mm

Label Position Eye

One photocell sensor to track printed labels

Waste Shaft

Web Guiding System

With two photoelectric eyes to control paper move straightly

Control Panel

All in English

Optional parts

Hot Stamping

Punching

Lamination

Slitting Unit

Samples

Certifications

OUR FACTORY

Hangzhou Depai Machinery Co., Ltd

has several production lines in different workshops from printing machines,bag making machine,label sticker die cutting & slitting machines, paper /PP/PLA straw machines,disposable products making machines ,to different plastic&paper and packaging machines.

We have a professional after-sales service team to provide you with high quality service. Engineers who can speak English can come to your factories or workshop to help you debug your machine and provide free training by video call .Our factory also cooperated with some famous French and German companies.Every year, our production director and technical director will go to the European cooperation technology companies or large factories for technical study.By communicating and learning from each other, it ensures the high quality of each machine and our technology is always far ahead in China.

Our Advantages

Raw Material Machining Center

Our Sales Team

Our Workshops

Packing

Interior: Wraping Film to keep dry and prevent from rusty

Outer: Sea-Worthy Wooden Case to keep machine safe in delivery.

FAQ

1.

Q: How does your factory do regarding quality control?

A: Quality is priority. We always regard great importance to quality controlling from the very small thing (even a small screw we will choose the best quality) from the beginning.

2. Q: What is your after-sales service?

A: Our after-sales service is first class. We have a powerful team to help you solve problems.The Warranty is one year and if the machine is damaged by natural not by human, we can send the new parts to you for free.

3. Q: What is the terms of payment you accept?

A: 30% T/T in advance, 70% T/T balance before delivery. We also accept L/C and Western Union.

A: Quality is priority. We always regard great importance to quality controlling from the very small thing (even a small screw we will choose the best quality) from the beginning.

2. Q: What is your after-sales service?

A: Our after-sales service is first class. We have a powerful team to help you solve problems.The Warranty is one year and if the machine is damaged by natural not by human, we can send the new parts to you for free.

3. Q: What is the terms of payment you accept?

A: 30% T/T in advance, 70% T/T balance before delivery. We also accept L/C and Western Union.

Hot Searches