- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

220V 60Hz

-

Dimension(L*W*H):

-

7700*1700*1400mm

-

Weight:

-

8000 kg

-

Machine Frame:

-

350mm H Beam Structure, With 18 mm Welded Steel Middle Support Plate

-

Material Of Rollers:

-

High Grade 45# Forged Steel Chromed Treatment

-

Forming Stations Roller Stations:

-

16+13 Rows

-

Transmission Way:

-

By 1 Inch Chain (Double Chains)

-

Main Motor:

-

5.5+4 kw

-

Cutting Blade Material:

-

Gcr12 quenched treatment

-

Cutting Type:

-

hydraulic post cutting

-

Driving Method:

-

Driving Method

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20M/MIN

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

220V 60Hz

-

Dimension(L*W*H):

-

7700*1700*1400mm

-

Weight:

-

8000 kg

-

Machine Frame:

-

350mm H Beam Structure, With 18 mm Welded Steel Middle Support Plate

-

Material Of Rollers:

-

High Grade 45# Forged Steel Chromed Treatment

-

Forming Stations Roller Stations:

-

16+13 Rows

-

Transmission Way:

-

By 1 Inch Chain (Double Chains)

-

Main Motor:

-

5.5+4 kw

-

Cutting Blade Material:

-

Gcr12 quenched treatment

-

Cutting Type:

-

hydraulic post cutting

-

Driving Method:

-

Driving Method

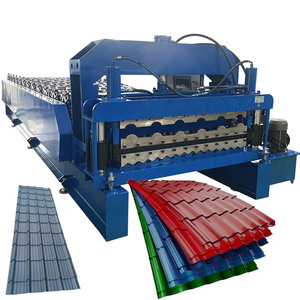

Product Display

Qué es aluzinc tr4 y tr5 ?

El aluzinc tr4 y tr5 es un material que combina las propiedades del aluminio y el zinc, lo que le confiere una excelente resistencia a la corrosión y durabilidad en diferentes ambientes. Sus nombres aluzinc tr4 y tr5 derivan de la cantidad de perfiles trapezoidales que presentan. Las coberturas de aluzinc son ampliamente utilizadas en la industria de la construcción debido a sus características beneficiosas.

5 tons manual decoiler

Capacity: 5T

Coil diameter:450-550mm

Type:manual(also can use the hydraulic decoiler as customers' request )

Coil width: 1200mm(as customers' request)

Coil diameter:450-550mm

Type:manual(also can use the hydraulic decoiler as customers' request )

Coil width: 1200mm(as customers' request)

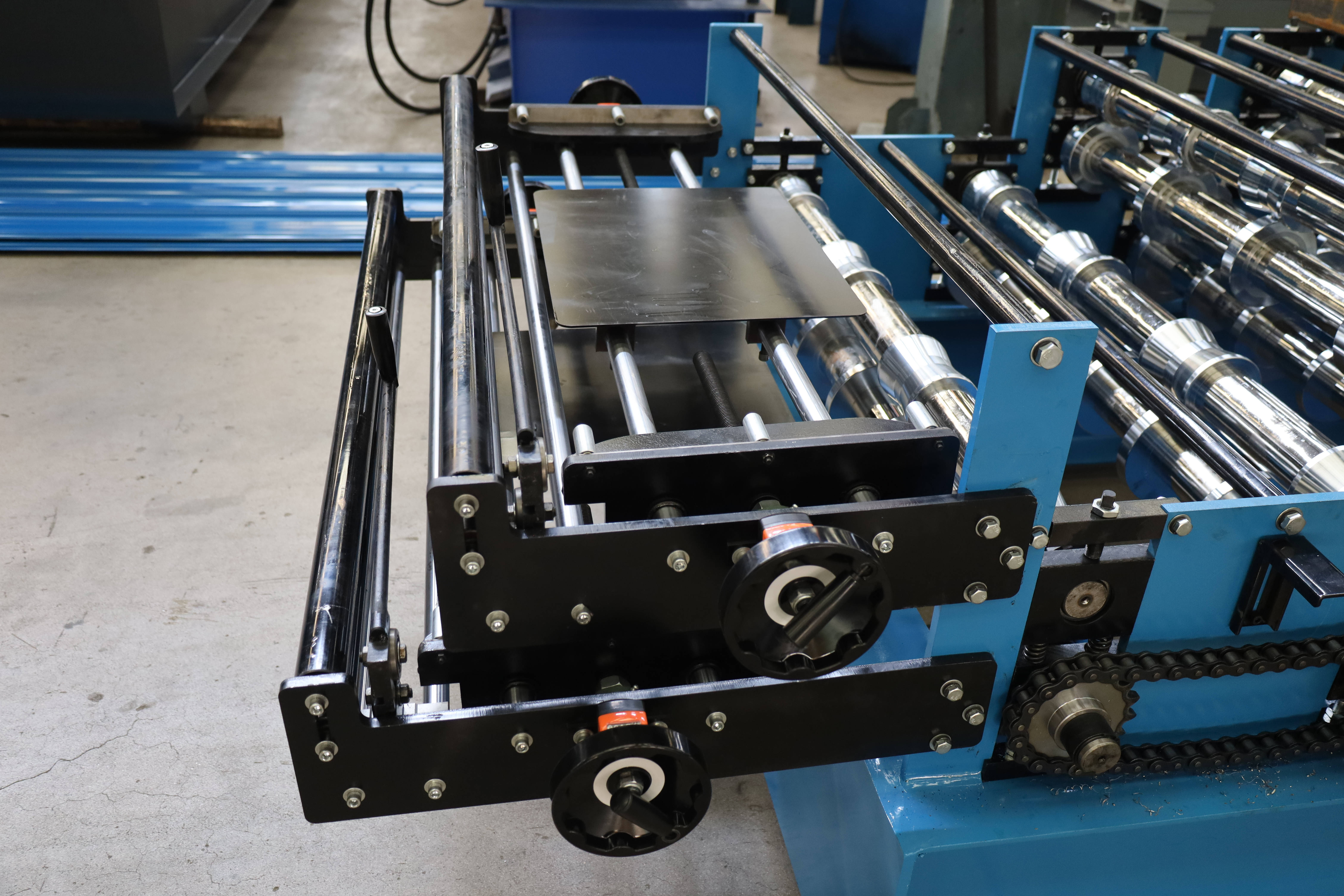

Feeding platform

1.Hand wheels on both sides can be used to adjust the feeding width. 2.Touch stainless rollers can make the material go into the machine smoothly and prevent the scratch on the material surface.

3. Pre-cutter can help cut off the material in advance if you want to change coil, save much material.

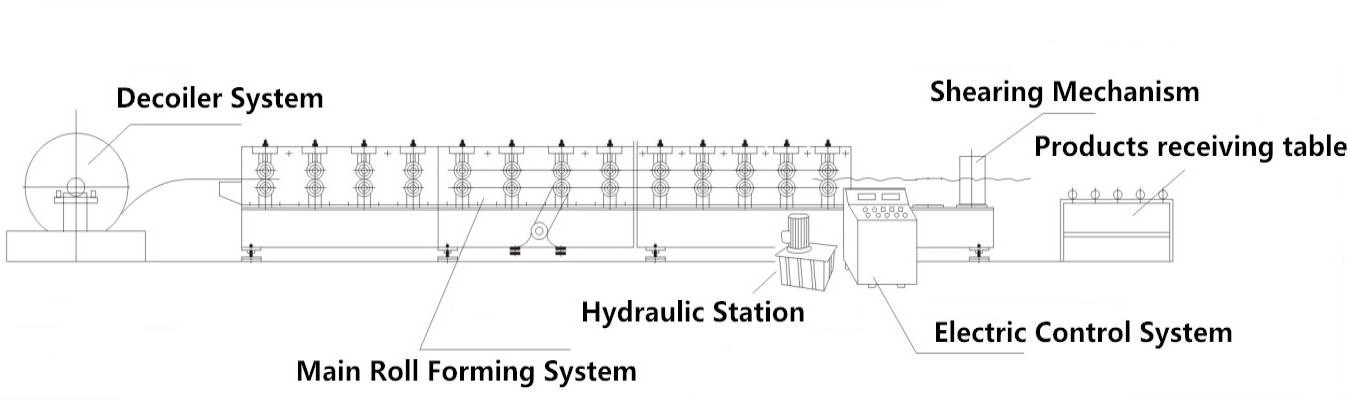

Main roll forming machine

Frame:350H steel

Roller stations:18+13 stations

Roller materila:45# steel with quenched treatment and hard chroming

Shaft material:45# steel with tempering treatment

Motor power:5.5kw

Roller stations:18+13 stations

Roller materila:45# steel with quenched treatment and hard chroming

Shaft material:45# steel with tempering treatment

Motor power:5.5kw

Control system

Control system:PLC

PLC brand:Delta from Taiwan

Frequency converter brand:Delta from Taiwan

Encoder:Omron

Function:Automatic control the length and quantity

PLC brand:Delta from Taiwan

Frequency converter brand:Delta from Taiwan

Encoder:Omron

Function:Automatic control the length and quantity

Automatic shearing system

The material of the blade : Cr12 MOV ,with quenched treatment.

power: 4KW

cutting tolerance:±1mm cutting system:electric cutting

power: 4KW

cutting tolerance:±1mm cutting system:electric cutting

Hydraulic station

One set

power: 4kw

With fan for longer working time

power: 4kw

With fan for longer working time

Hydraulic oil:46# hydraulic oil

Main components:Include a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And one of electromagnetism valve

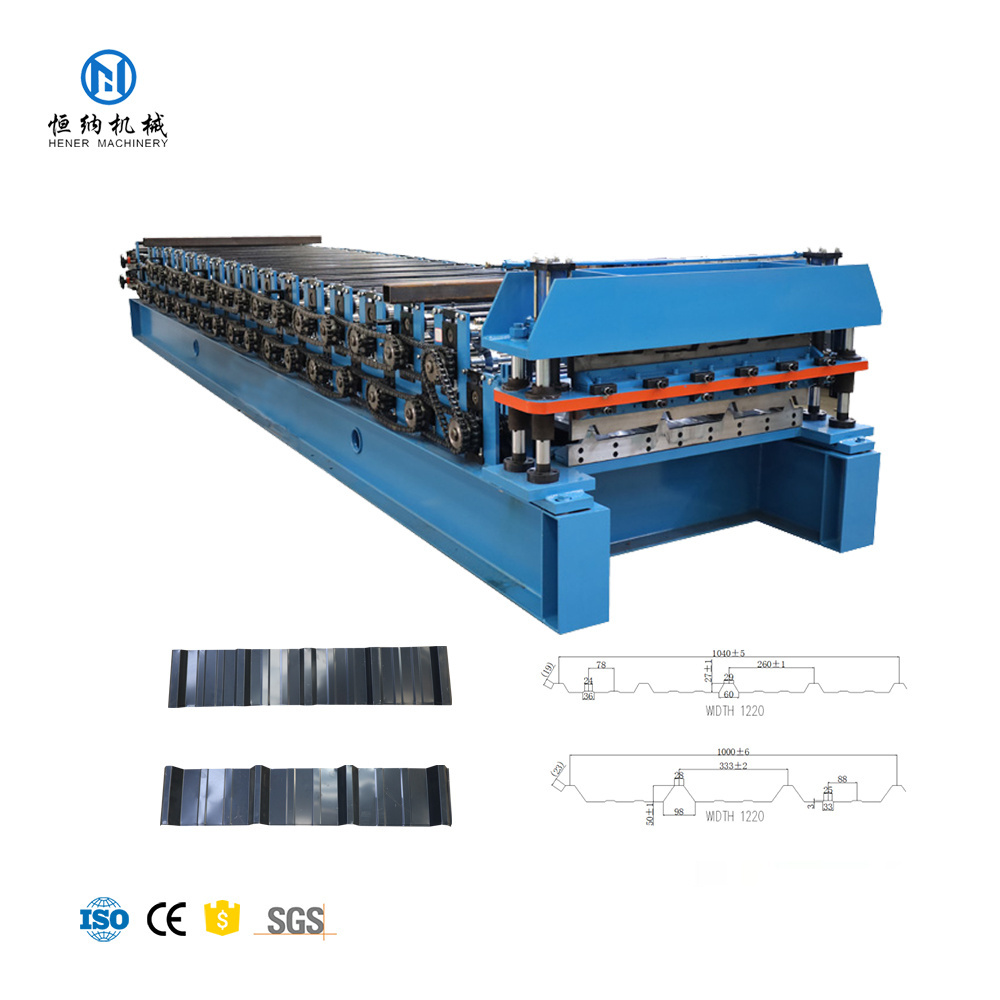

Product Paramenters

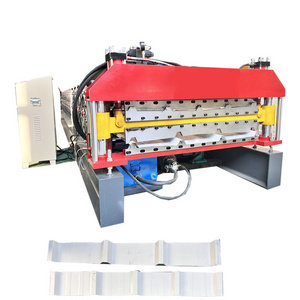

Double Layers Roofing Sheet Machine IBR Tile Making Machine

Corrugated Trapezoid TR4/TR5 Roof Panel Roll Forming Machine

1) Operación del equipo: Automáticamente

2) Voltaje: como su requisito

3) Grosor de la hoja (mm): 0,3-0,8 mm

4) Material: GI, GL, PPGI, PPGL

5) Productividad: casi 20 M/min

6) Estaciones de rodillos: 18+13 Rodillos

2) Voltaje: como su requisito

3) Grosor de la hoja (mm): 0,3-0,8 mm

4) Material: GI, GL, PPGI, PPGL

5) Productividad: casi 20 M/min

6) Estaciones de rodillos: 18+13 Rodillos

Material de los rodillos: acero C45 templado y cromado

Bobina: galvanizada y pintada

7) Potencia total (kw): 5,5 + 4kw

8)Potencia del sistema hidráulico: 4kw

9)Potencia del núcleo de moldeo principal: 5.5kw

10) Método de corte: sistema de corte hidráulico

11)Control electrónico: PLC Delta

Bobina: galvanizada y pintada

7) Potencia total (kw): 5,5 + 4kw

8)Potencia del sistema hidráulico: 4kw

9)Potencia del núcleo de moldeo principal: 5.5kw

10) Método de corte: sistema de corte hidráulico

11)Control electrónico: PLC Delta

1) Equipment operation: Automatically

2) Voltage: as per your requirement

3) Sheet thickness (mm): 0.3-0.8 mm

4) Material:

GI, GL, PPGI, PPGL

5) Productivity: approximately 20 M/min

6) Roller stations: 18+13 Roller

Material: hardened and chrome-plated C45

steel

Coil:galvanized and painted

7) Total power (kw): 5.5 + 4kw

8) Hydraulic system power: 4kw

9) Main molding core power: 5.5kw

10) Cutting method: hydraulic cutting system

11) Electronic control: Delta PLC

Cases

Ventajas de usar coberturas de aluzinc

|

1.Resistencia a la corrosión:

|

|

El recubrimiento de aluzinc proporciona una excelente protección contra la corrosión, lo que ayuda a prolongar la vida útil de la

cobertura y reducir los costos de mantenimiento a largo plazo. |

|

|

|||

|

2.Durabilidad:

|

|

El recubrimiento de aluzinc proporciona una excelente protección contra la corrosión, lo que ayuda a prolongar la vida útil de la

cobertura y reducir los costos de mantenimiento a largo plazo. |

|

|

|||

|

3.Ligereza:

|

|

A pesar de su resistencia, las coberturas de aluzinc son relativamente ligeras, lo que facilita su manipulación e instalación.

|

|

|

|||

|

4.Versatilidad:

|

|

Estas coberturas están disponibles en una variedad de perfiles y colores.

|

|

|

|||

|

5.Bajo mantenimiento:

|

|

El aluzinc no requiere un mantenimiento extenso, lo que supone ahorro de tiempo y dinero a largo plazo.

|

|

|

|||

Hot Searches