- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 years

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GOLDENMAN

-

Model Number:

-

API 5CT

-

Product name:

-

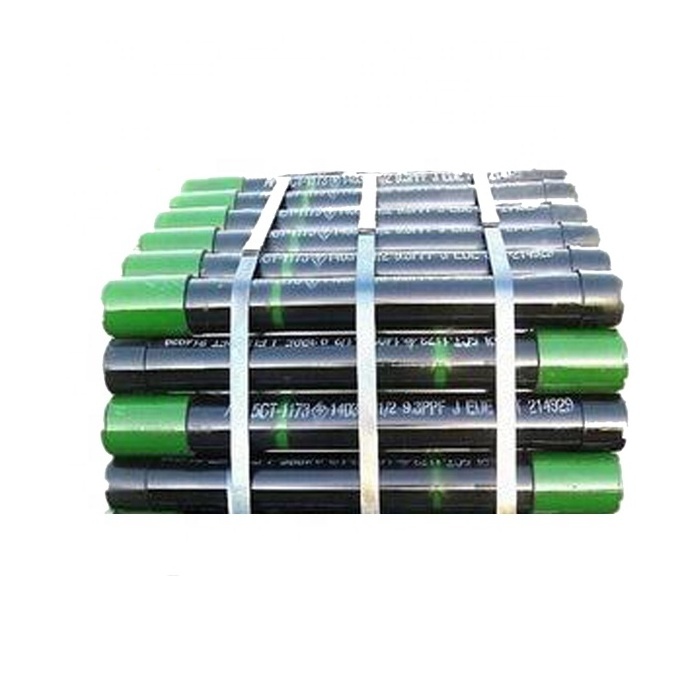

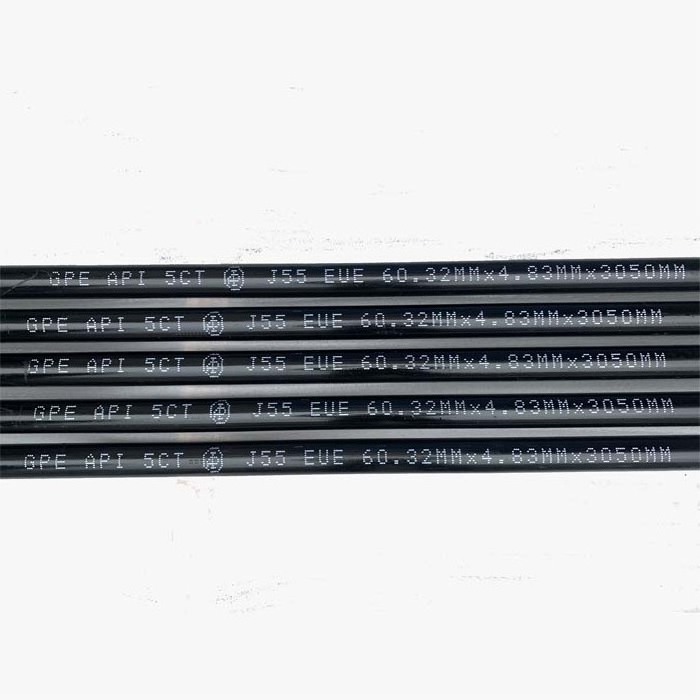

API 5CT PUP JOINT / tubing pipe with coupling 2.3/8" J55 EU 10FT

-

Keyword:

-

PUP JOINT / tubing pipe

-

size:

-

60.3x4.83mm

-

Surface:

-

Black Painted

-

Material:

-

J55

-

End protector:

-

Plastic Pipe Cap

-

Ends:

-

coupling and plastic pipe cap

-

type of end:

-

EU

-

Length:

-

3.05meter/10FT

Quick Details

-

Technics:

-

Casting

-

Shape:

-

Equal

-

Head Code:

-

Round

-

Warranty:

-

1 years

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GOLDENMAN

-

Model Number:

-

API 5CT

-

Product name:

-

API 5CT PUP JOINT / tubing pipe with coupling 2.3/8" J55 EU 10FT

-

Keyword:

-

PUP JOINT / tubing pipe

-

size:

-

60.3x4.83mm

-

Surface:

-

Black Painted

-

Material:

-

J55

-

End protector:

-

Plastic Pipe Cap

-

Ends:

-

coupling and plastic pipe cap

-

type of end:

-

EU

-

Length:

-

3.05meter/10FT

Products Description

TUBING AND

TUBING PUP JOINT

Delivey time

25 days!

Products conform

to API standards

Firm connection,

good sealing,

multiple use and long life

GENERAL PRODUCTS CONFORM TO API STANDARDS.AND

PATENTED ONES HAVE EVEN BETTER PERFORMANCE

Product Paramenters

|

Tubing coupling

|

|

|

|

|

||||

|

Size and Specifications For Tubing and Casing Couplings.

|

|

|

|

|

||||

|

Descriptions and size

|

|

Type of Therad

|

O.D*L

(mm) |

Weight

(kg) |

||||

|

Tubing Coupling

|

1.050

|

NUE

|

33.35*80.96

|

0.23

|

||||

|

|

1.050

|

EUE

|

42.16*82.55

|

0.38

|

||||

|

|

1.315

|

NUE

|

42.16*82.55

|

0.38

|

||||

|

|

1.315

|

EUE

|

48.26*88.90

|

0.57

|

||||

|

|

1.660

|

NUE

|

52.17*88.90

|

0.59

|

||||

|

|

1.660

|

EUE

|

58.88*95.25

|

0.68

|

||||

|

|

1.900

|

NUE

|

55.88*95.25

|

0.56

|

||||

|

|

1.900

|

EUE

|

63.50*98.42

|

0.84

|

||||

|

|

2-3/8"

|

NUE

|

73.02*107.95

|

1.28

|

||||

|

|

2-3/8"

|

EUE

|

77.80*132.82

|

1.55

|

||||

|

|

2-7/8"

|

NUE

|

88.90*130.18

|

2.34

|

||||

|

|

2-7/8"

|

EUE

|

93.17*133.35

|

2.40

|

||||

|

|

3-1/2"

|

NUE

|

107.95*142.88

|

3.71

|

||||

|

|

3-1/2"

|

EUE

|

114.30*146.05

|

4.10

|

||||

|

|

4"

|

NUE

|

120.65*146.05

|

4.35

|

||||

|

|

4"

|

EUE

|

127.00*152.40

|

4.82

|

||||

|

|

4-1/2"

|

NUE

|

132.08*155.58

|

4.89

|

||||

|

|

4-1/2"

|

EUE

|

141.30*158.75

|

6.05

|

||||

|

Casing Coupling

|

4-1/2"

|

STC

|

127.00*158.75

|

5.23

|

||||

|

|

4-1/2"

|

LTC

|

127.00*177.80

|

4.15

|

||||

|

|

4-1/2"

|

BTC

|

127.00*225.42

|

4.55

|

||||

|

|

5"

|

STC

|

141.30*165.10

|

4.66

|

||||

|

|

5"

|

LTC

|

141.30*196.85

|

5.75

|

||||

|

|

5"

|

BTC

|

141.30*231.78

|

5.85

|

||||

|

|

5-1/2"

|

STC

|

153.67*171.45

|

5.23

|

||||

|

|

5-1/2"

|

LTC

|

153.67*203.20

|

6.42

|

||||

|

|

5-1/2"

|

BTC

|

153.67*234.95

|

6.36

|

||||

|

|

6-5/8"

|

STC

|

187.71*184.15

|

9.12

|

||||

|

|

6-5/8"

|

LTC

|

187.71*222.25

|

11.34

|

||||

|

|

6-5/8"

|

BTC

|

187.71*244.48

|

11.01

|

||||

|

|

7"

|

STC

|

194.46*184.15

|

8.39

|

||||

|

|

7"

|

LTC

|

194.46*228.60

|

10.83

|

||||

|

|

7"

|

BTC

|

194.46*254.00

|

10.54

|

||||

|

|

7-5/8"

|

STC

|

215.90*190.50

|

12.30

|

||||

|

|

7-5/8"

|

LTC

|

215.90*234.95

|

15.63

|

||||

|

|

7-5/8"

|

BTC

|

215.90*263.52

|

15.82

|

||||

|

|

8-5/8"

|

STC

|

244.48*196.85

|

16.23

|

||||

|

|

8-5/8"

|

LTC

|

244.48*254.00

|

21.67

|

||||

|

|

8-5/8"

|

BTC

|

244.48*269.88

|

20.86

|

||||

|

|

9-5/8"

|

STC

|

269.88*196.85

|

18.03

|

||||

|

|

9-5/8"

|

LTC

|

269.88*266.70

|

25.45

|

||||

|

|

9-5/8"

|

BTC

|

269.88*269.88

|

23.16

|

||||

|

|

10-3/4"

|

STC

|

298.45*203.20

|

20.78

|

||||

|

|

10-3/4"

|

BTC

|

298.45*269.88

|

25.74

|

||||

|

|

11-3/4'

|

STC

|

323.85*203.20

|

22.64

|

||||

|

|

11-3/4'

|

BTC

|

323.85*269.88

|

28.03

|

||||

|

|

13-3/8"

|

STC

|

365.12*203.20

|

25.66

|

||||

|

|

13-3/8"

|

BTC

|

365.12*269.88

|

31.77

|

||||

|

|

16"

|

STC

|

431.80*228.6

|

34.91

|

||||

|

|

16"

|

BTC

|

431.80*269.88

|

40.28

|

||||

|

|

18-5/8"

|

STC

|

508.00*228.60

|

51.01

|

||||

|

|

18-5/8"

|

BTC

|

508.00*269.88

|

62.68

|

||||

|

|

20"

|

STC

|

533.40*228.6

|

43.42

|

||||

|

|

20"

|

LTC

|

533.4*292.10

|

57.04

|

||||

|

|

20"

|

BTC

|

533.40*269.88

|

50.10

|

||||

Our products

PREMIUM CONNECTION/RTJ-DTG3

STRUCTURE

PERFORMANCE

• Quick running: RTJ-DTG3 has rugged thread, 3 TPI versus buttress 5 TPL. It is much quicker when the consumer makeup this connection.

• Higher connecting strength: thread load flank is 90°to resist jump-out, it is designed for maximum connecting efficiency.

• Thread stabbing flank has a 30° angle for fast,trouble-free makeup.

• Easy stabbing and no cross-threading. Crests and roots parallel to pipe axis.

• RTJ-DTG3 is suitable for casing in OD above 14 in. RTJ-DTG3 is acoupled connection. The thread is cut directly into the pipe and the coupling. The risks associated with weld-on connectors are eliminated.

• Standard coupling OD are identical with API.Higher grades and larger wall thicknesses are permitted if necessary.The standard coupling length is 10 5/8”(269.9 mm) as with APl.

• RTJ-DTG3 possesses the rugged thread profile featuring: 3TPL,Taper 1:8.Thread height 2.1 mm, load flank 90", stabbing flank 30°.

PREMIUM CONNECTION/ RTN-14AM

STRUCTURE

• Coupling connection type, the connection streng-th reaches to or over that of pipe body.

• Thread is improved buttress thread with high connecting efficiency, which is easy to process.

2 3/8"-2 7/8” 8 TPI 3 1/2”-4 1/2” 6 TPI 5" and over 5 TPI

• Main seal adopts taper to taper seal structure with negative angle torque shoulder to enhance its seal ability.

• The reverse torque shoulder improves the connection capacity of bearing combined load.

• The inner wall of pipe body aligns with the coupling inner wall.

PERFORMANCE

• Connection strength: the connection with standard coupling can reach to the strength of pipe body.

• Seal property: the low angle taper to taper interference seal,further strengthened by the reverse angle torque shoulder.The multi seal configuration ensures the connection to have high seal reliability.

• With the reverse torque shoulder, the joint has high capability to resist the compression, bend and over-torque loads.

• lnner flat design reduces the gas and liquid turbulence in the pipe,so lower the energy loss.

• Anti-galling design: it is permitted to makeup and breakout for several times.

PREMIUM CONNECTION/ RTV-200P

STRUCTURE

• Coupling design: Coupling critical cross sections are greater than those of the pipe body.

• A modified hook thread profile with-4°reverse angle on the load flank,10°angle on the lead flank. This not only provides the connection with super-ior tension strength, but also increases its resista-nce to compression.

2 3/8"-2 7/8”8 TPI 3 1/2"-41/2”6 TPI 5"-7 3/4" 5 TPI 8 5/8" up 4TPI

• A patented taper metal-to-metal seal system offers excellent gas-tight sealing. under even the most severe combined toads, such as bending and temperature loads.

• A reverse angle torque shoulder provides a positive torque stop which allows for accurate power-tight makeup and minimizes hoop stresses in the connection.

PERFORMANCE

• Connecting strength: the connection with stand-ard coupling can reach to the strength of pipe bo-dy.

• Seal property: the low angle taper to taper interf-erence seal, further strengthened by the reverse angle torque shoulder. The multi seal configuration ensures the connection to have high seal reliabili-ty.

• With the hook thread and reverse torque should-er, the joint has high capability to resist the compr-ession, bend and over-torque loads.

• lnner flat design reduces the gas and liquid turb-ulence in the pipe, so lower the energy loss.

• Anti-galling design: it is permitted to makeup and breakout for several times.

PREMIUM CONNECTION/RTT-16H6

STRUCTURE

• Connection is designed with extreme-line thread without coupling.·

• Joint external upset.

• RTT-16H6 adopts straight, non-interference thread style.Loading surface angle is 7.5°, stabbing surface angle is 20°.RTT-CS is 8 TPL,RTT-16H6 is 6 TPI, RTT-14H4 is 4 TPI.

• Metal-to-metal internal pressure seal is rated at 100% of the pipe body.The 100% external pressure seal is created at the torque shoulder.

• External shoulder designed with -60° negative angle shoulder,internal shoulder is rectangle shoulder.

• Surface treatment: internal and external thread needs phosphate treatment.

PERFORMANCE

• The two-step, non-interference thread style provides RTT-CS/RTT-16H6/RTT-14H4 with very good galling resistance.

• H2S service suitability is ensured by combining the low stress profile of non-interference threads with fixed make-up position control of a shouldered connection.

• The 100% external pressure seal is created at the torque shoulder.Metal-to-metal internal pressure seal is rated at 100% of the pipe body.

• 100% pipe body tension strength is produced by machining pin and box on a hot-forged upset.Connection critical areas exceed the pipe body area.

• High torque strength is provided by the reverse angle shoulder.The shoulder also provides excellent resistance to compression and bending loads.

R&D capabilities and all-in-one solutions

56 countries - Supplier of world-renowned drilling companies

50+ Years - Experience in drilling rig equipment of our cooperative partner.

Complete global supply chain management system

Test Report

Customer Photos

Hot Searches