- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SiC

-

Shape:

-

Round

-

Material:

-

SiC

-

Chemical Composition:

-

SiC99.5%

Quick Details

-

Application:

-

Sputtering Coating

-

Place of Origin:

-

China

-

Brand Name:

-

Rheniumet

-

Model Number:

-

SiC

-

Shape:

-

Round

-

Material:

-

SiC

-

Chemical Composition:

-

SiC99.5%

Products Description

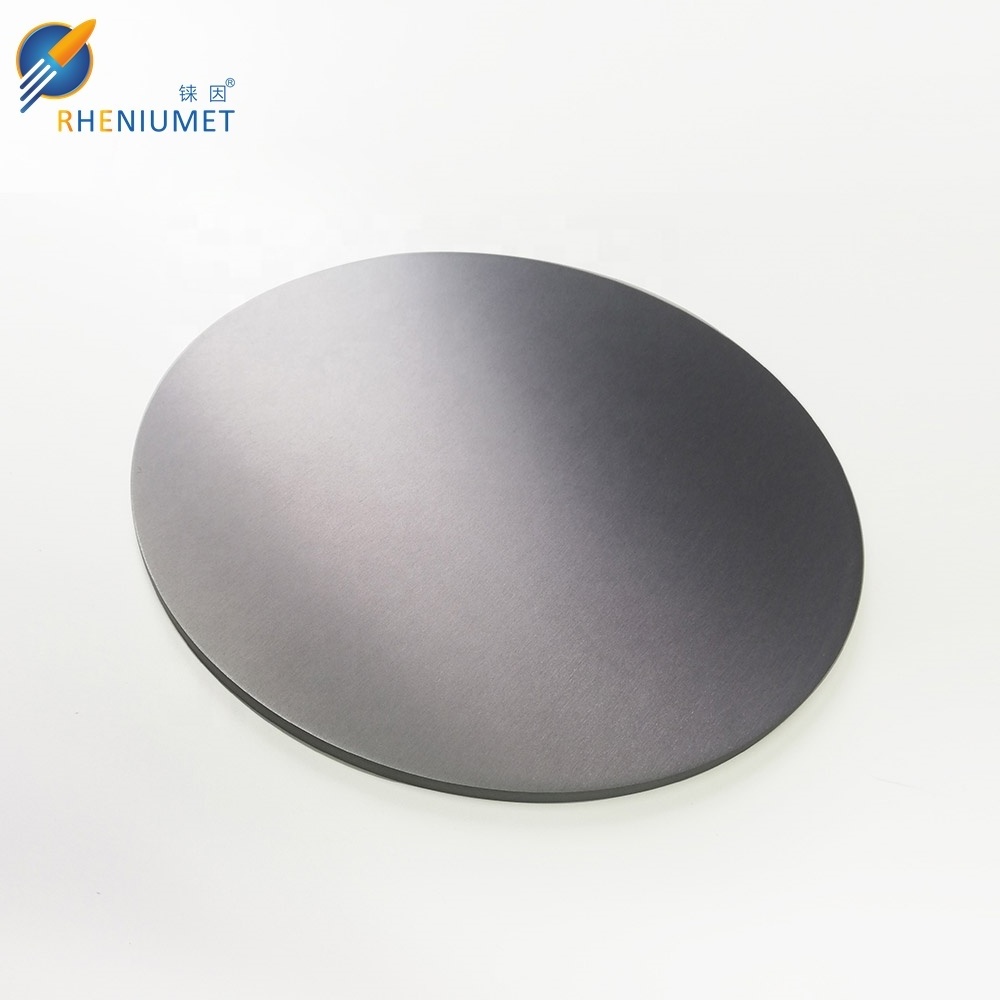

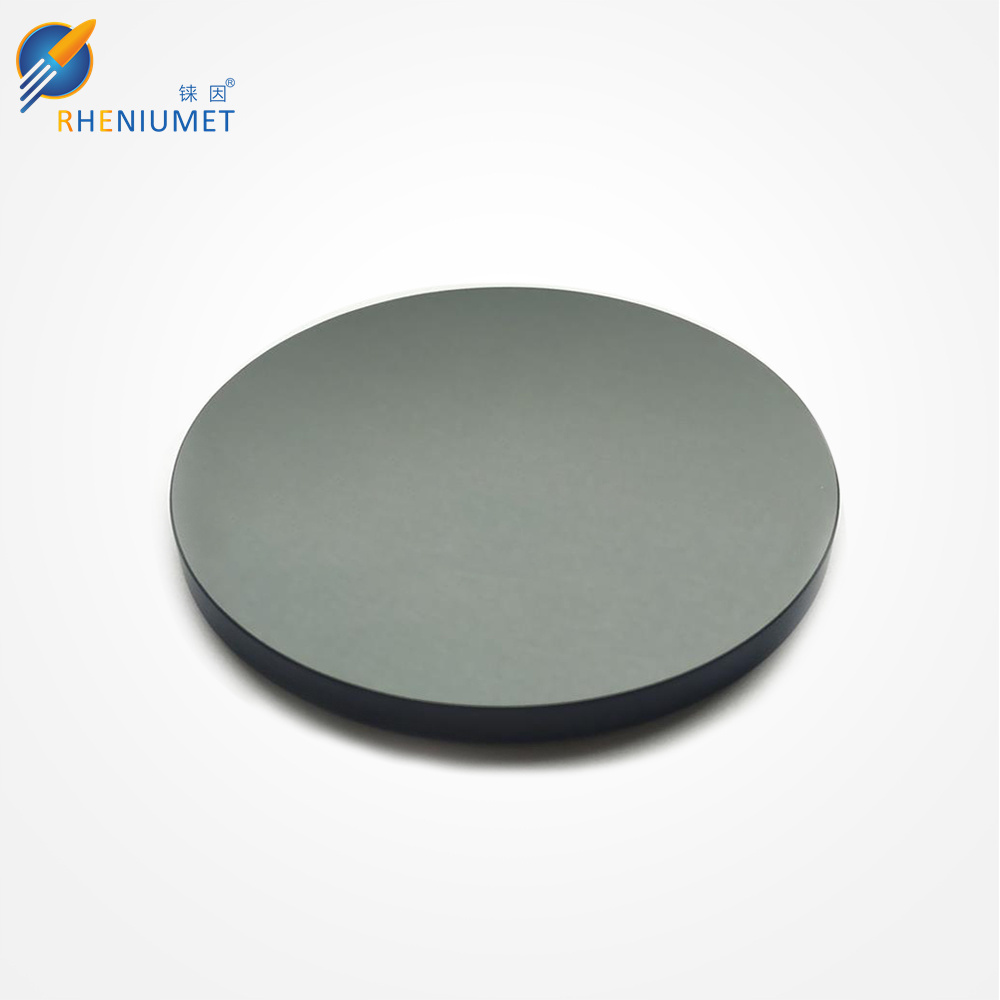

Silicon carbide target material

Silicon carbide is the third generation semiconductor material, with wide band gap, high thermal conductivity, high saturation electron drift speed, high critical breakdown electric field and low dielectric constant, good chemical stability, etc., in high frequency, high power, high temperature resistance, anti-radiation semiconductor devices and UV detector lamps have a wide range of applications.

Specification:

Specification:

|

Physical properties

|

Color

|

black

|

|

|

|

Density

|

3.22g/cm³

|

|

|

|

Melting point

|

2830ºC

|

|

|

Technical specifications

|

Purity

|

99.5%

|

|

|

|

Relative density

|

>99%

|

|

|

|

Flatness of section

|

3.2Ra

|

|

|

|

Tolerance

|

±0.1mm

|

|

|

|

grain size

|

well-distributed

|

|

|

Material

|

SiC

|

|

|

|

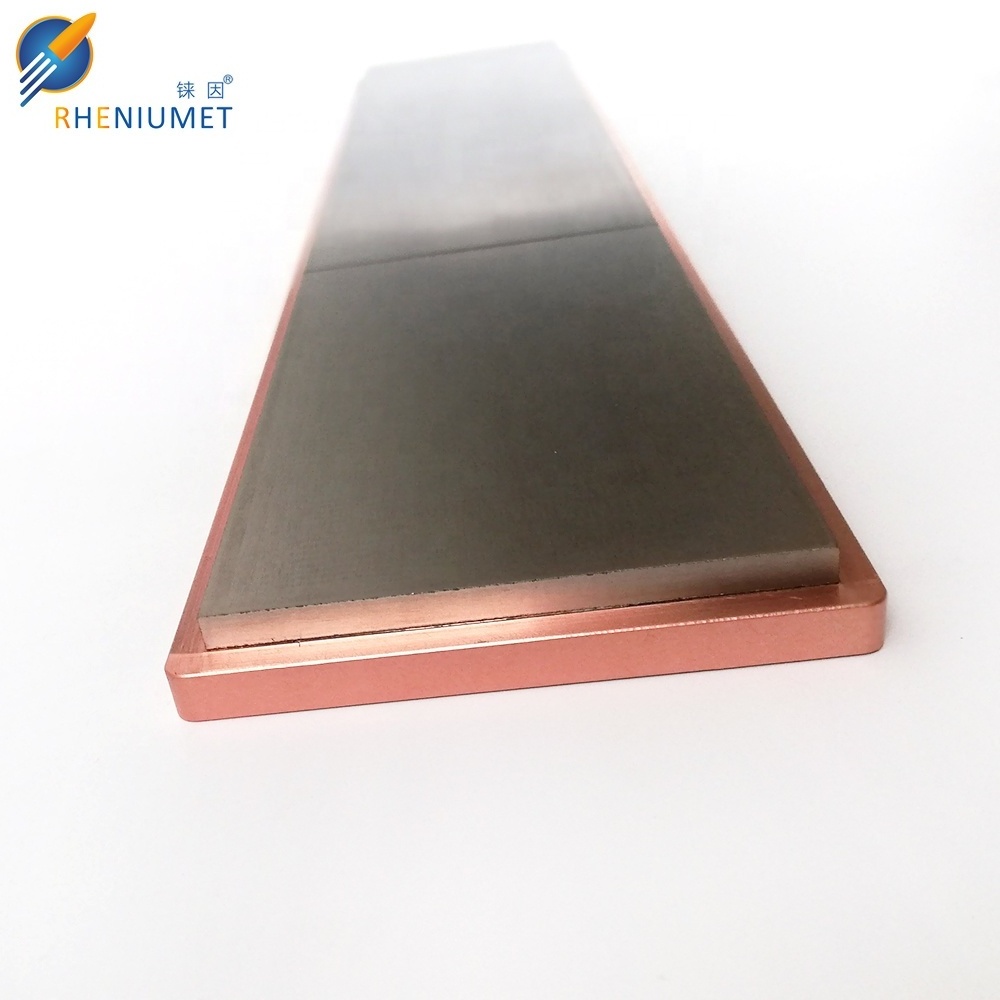

Product Specification

|

Disc/table/rod: diameter <360mm thickness >1mm

|

|

|

|

|

Rectangle/sheet/step shape (splicing) : length <300mm width <300mm thickness >1mm

|

|

|

|

|

Pipe/ring/rotating target) : Outer diameter <360mm inner diameter >1mm wall thickness >1mm length >1mm

|

|

|

|

|

According to the needs of users to customize, sample processing, to map processing

|

|

|

|

Minimum order quantity

|

1 piece, large quantity discount

|

|

|

|

Production process

|

Vacuum magnetic levitation melting, casting into ingot, thermal mechanical treatment and precision machining

|

|

|

|

Applicable instruments:

|

various types of magnetron sputtering equipment

|

|

|

|

Product advantages

|

1.Reliable quality, favorable price

2.Vacuum melting, purification preparation, high purity, less impurities 3.Compact rolling, less oxidation, molding plastic 4.High relative density, uniform grain equiaxial, high consistency |

|

|

|

Product accessories

|

Official quotation/purchase and sales contract/packing list/Material analysis and inspection list/formal invoice

|

|

|

|

Packing method

|

Vacuum packing/vacuum neutral packing/Special packing external reinforcement packing

|

|

|

Application field

Commonly used in aerospace, biomedical, military, automotive, electronics, new energy, integrated circuits, information storage and so on.

Hot Searches