- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3000*1300*1600mm

-

Weight:

-

40 KG

-

Product name:

-

Plastic Bottle Capping Machine

-

Keywords:

-

Automatic Capping Machine

-

Bottle type:

-

Plastic Bottle Glass Bottle Cans

-

Applicable caps:

-

automatic Spray Capping Machine

-

Function:

-

Capper Cap-locking Machine

-

Suitable for:

-

Glass Bottle Plastic Bottle

-

Material:

-

Stainless Steel 304 / SUS316L

-

Capping type:

-

Screw Capping Locking

-

Production capacity:

-

50- 80 Bottles/min

-

Speed:

-

30-60 Pcs/min

Quick Details

-

Voltage:

-

220v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HY

-

Dimension(L*W*H):

-

3000*1300*1600mm

-

Weight:

-

40 KG

-

Product name:

-

Plastic Bottle Capping Machine

-

Keywords:

-

Automatic Capping Machine

-

Bottle type:

-

Plastic Bottle Glass Bottle Cans

-

Applicable caps:

-

automatic Spray Capping Machine

-

Function:

-

Capper Cap-locking Machine

-

Suitable for:

-

Glass Bottle Plastic Bottle

-

Material:

-

Stainless Steel 304 / SUS316L

-

Capping type:

-

Screw Capping Locking

-

Production capacity:

-

50- 80 Bottles/min

-

Speed:

-

30-60 Pcs/min

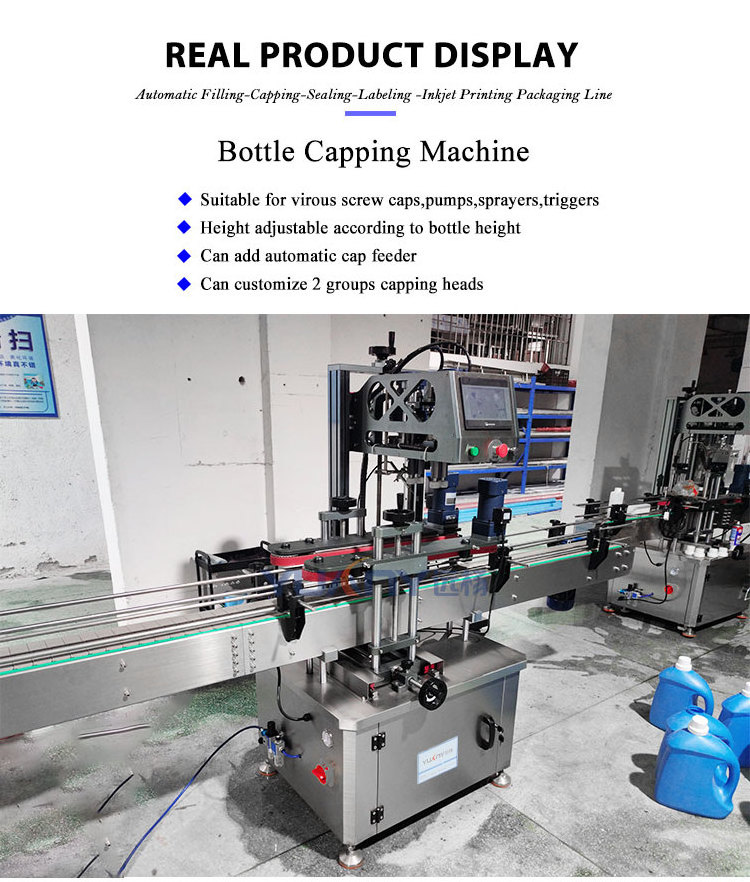

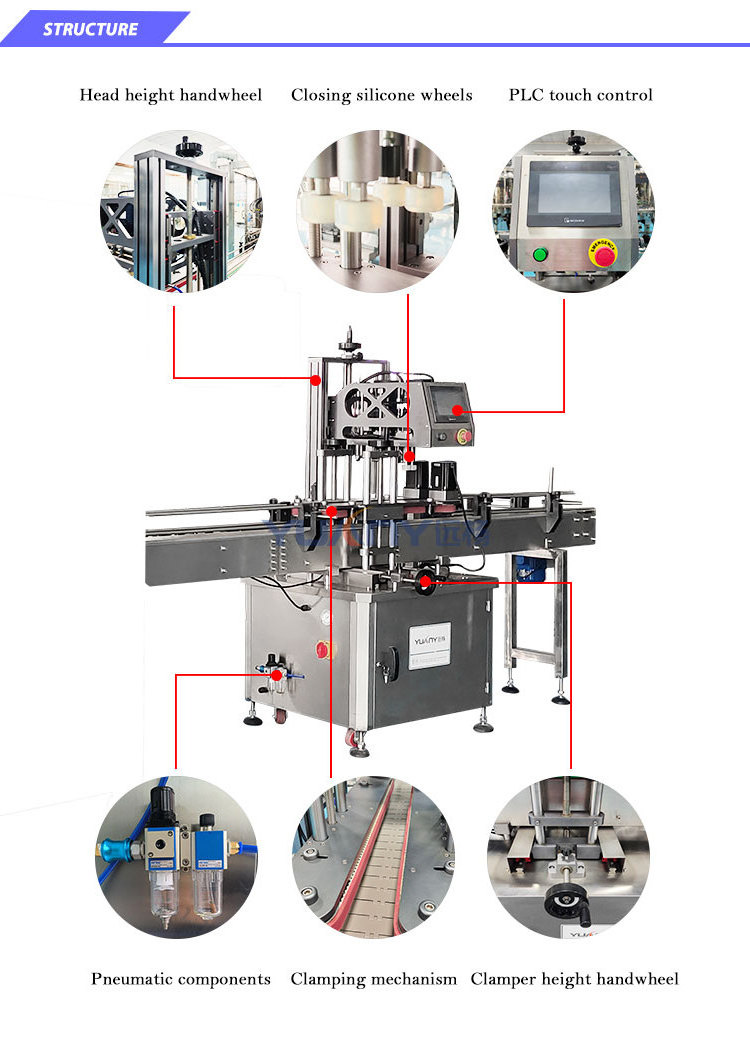

Automatic Plastic Screw Caps Twisting Closing Tightening Capping Machine

Introduction:

Automatic capping machine is improved by referring to international advanced models, with fast capping speed, high pass rate and easy operation. Suitable for capping with different bottle shape in food, daily chemical, pesticide and other industries. The machine has high degree of automation and good stability while bottle clamping, transmission, capping. It is with easy adjustment, just replace the bottle or cap,The lid feeder can be added according to actual needs.

| Product Name | Automatic 4 Wheels Plastic Capping Machine |

| Voltage |

AC 220v 50hz (single phase) |

| Power |

1500w |

| Cap diameter |

22-80mm |

| Bottle diameter | 35-130mm |

| Bottle height | 38-300mm |

| Screw speed | 0-150 bot/min |

| Capping speed |

1800-2500pcs/hour |

| Discharge Method |

2*0.8*1.6m |

| OEM service: we custmoize according to requirements,just tell us your needs. Manager Ali | |

Q1: What products do you have?

A1: We are a factory specialized in daily cosmetic and liquid washing equipments. Such as, water treatment, vacuum emulsifier, shampoo and liquid soap mixers , detergent powder production equipment, storage tank, filling and capping,labeling machines, and other packing machines.

Q2: Can I visit your factory?

A2: Yes,welcome to visiting our factory.Our factory is located in Guangzhou, China. You could visit us by taxi or by metro. Our company can pick you up.

Q3: How is the quality?

A3: We provide high-standard equioments.Quality is priority. People from Yuanyang always attach great importance to quality control from the beginning to the end. We support production inspection before shipment Our factory has gained GMP,ISO,and CE Certificates.

Q4: What’s the guarantee if we purchase from you?

A4: All the equipment ordered from us will be provided with one years guarantee from the delivery date .If there is any wearing part broken within the warranty and isn’t caused by improper operation, we would offer the new parts for free.

Q5: How about the after-service?

A5: There’s no problem we could send our engineer to install or fix the machine locally, but customers need to pay the round air tickets cost and arrange the hotel accommodation for our engineer.

Q6: I don’t come to the company, how can I learn the machines?

A6: We provide video & manual instructions of the machines you purchase and online service,as well as face-to-face teaching.If you come to the company,our technical staff will teach you hand by hand.

Q7: What's the leading time and shipping way?

A7: We usually deliver by sea or train, which is cost-effective,and other ways as you require. The leading time depends on order quantity and machine items! For small order quantity of standard machine, we will have stock. For large quantity of standard machine and other customized machines, it needs 15-45 days. We will confirm details with customers before place orders!