- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

BSF

-

name:

-

It is Concrete Plastic mould Paver

-

Type:

-

It is Curbstones

-

color:

-

white .

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Oceana

-

Model Number:

-

BSF

-

name:

-

It is Concrete Plastic mould Paver

-

Type:

-

It is Curbstones

-

color:

-

white .

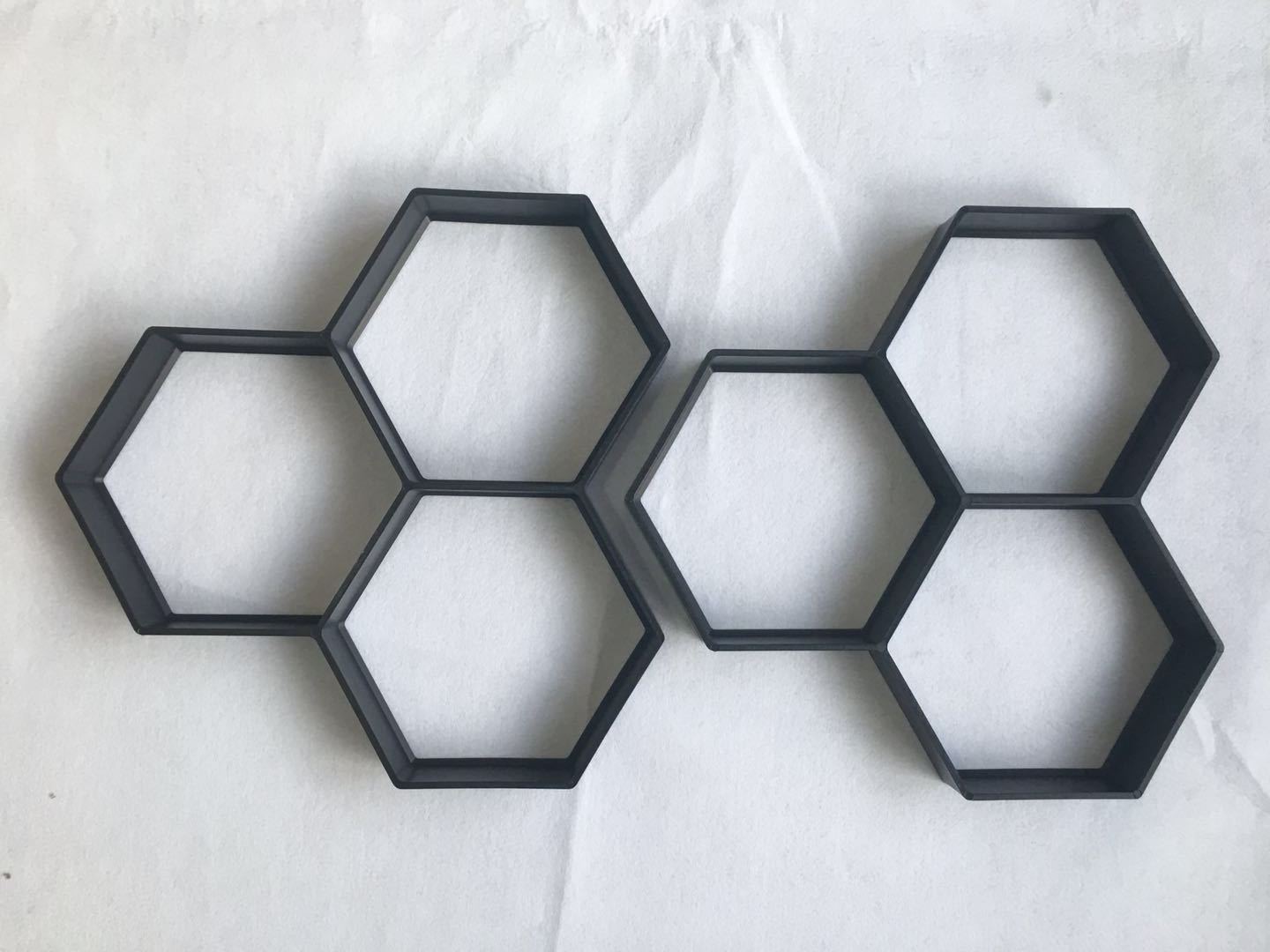

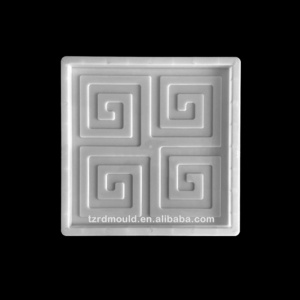

New Design High Quality Plastic Mould for diy concrete paver molds, block pavers

Curb use of engineering plastic mold pp (polypropylene) raw materials determines the appearance and quality of the mold, so it has good malleability, machinability, hardenability, hardenability and can grind, but also has a small oxidation, decarburization sensitivity and deformation hardening cracking tendency of such materials will also be low vacuum mold surface hardening treatment, so the durability of the mold to a new level. Curb mold-produced raw materials are optional level manufacturing, quality and reliable

The greatest benefit of plastic mold:

1, easy to operate, saving time and effort, without dismantling steel

2, precast concrete products smooth surface, high strength, there is a rough surface pores

3, the error between the plastic mold made out by product dimensionally stable product is not more than 1 millimeter, more susceptible to acceptance by the construction unit quality inspection departments

4, low cost, high return, the device is simple, quick operation, reliable quality