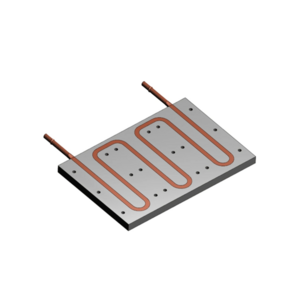

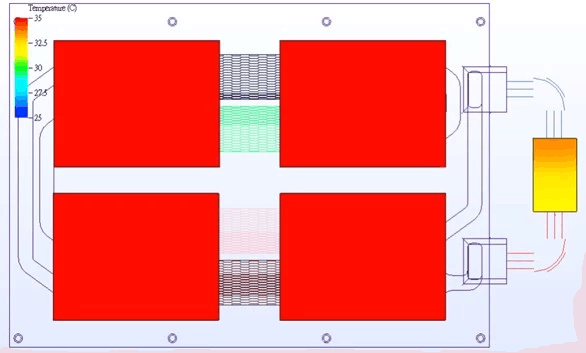

Use FLUENT,ICEPAK software to build a model,partition grill, set up boundary conditions and parameters, then make calculaitons to get temperature fields and flow f ileds distribution of heat exchangers. Further to get the desired parameters for antminer cold plate.

- Product Details

- {{item.text}}

Quick Details

-

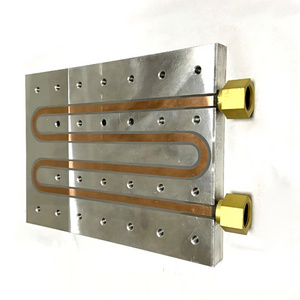

Manufacturing process:

-

CNC Machining and Bonding

-

Bonding process:

-

Epoxy bonding, vacuum brazing, aluminum extrusion and stamping

-

Surface finish:

-

Clean

-

Cooling capacity:

-

Custom

-

Maximum operating temperature:

-

400° C

-

Maximum pressure:

-

6mpa (60bar)

-

Dimensional tolerance:

-

ISO 2768 standard

-

Packaging:

-

The best packaging method

-

Certification:

-

SGS

Quick Details

-

Tolerance:

-

±1%

-

Place of Origin:

-

China

-

Material:

-

Aluminum Alloy

-

Manufacturing process:

-

CNC Machining and Bonding

-

Bonding process:

-

Epoxy bonding, vacuum brazing, aluminum extrusion and stamping

-

Surface finish:

-

Clean

-

Cooling capacity:

-

Custom

-

Maximum operating temperature:

-

400° C

-

Maximum pressure:

-

6mpa (60bar)

-

Dimensional tolerance:

-

ISO 2768 standard

-

Packaging:

-

The best packaging method

-

Certification:

-

SGS

|

Product name

|

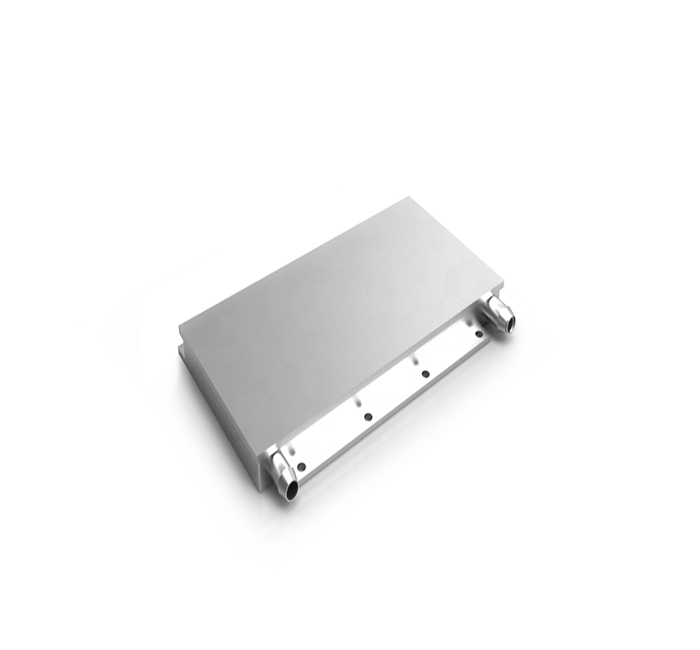

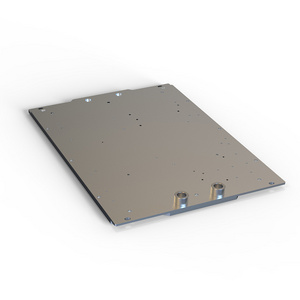

OEM Vacuum Brazed Water Cooling Plate

|

|

Material

|

Appropriate aluminum alloy ,aluminum

|

|

Dimensions

|

As per required

|

|

Dimension tolerance

|

ISO2768 standard

|

|

Flatness

|

0.05mm

|

|

Manufacturer

|

Metalli

|

|

Cooling capacity

|

As per specification

|

|

Application

|

Power Electronics, Military & Aerospace, Medical Lasers & Diagnostic Equipments, Industrial Lasers, Cabinet Cooling, Semiconductor Equipments, Telecommunications, Transducers,etc.

|

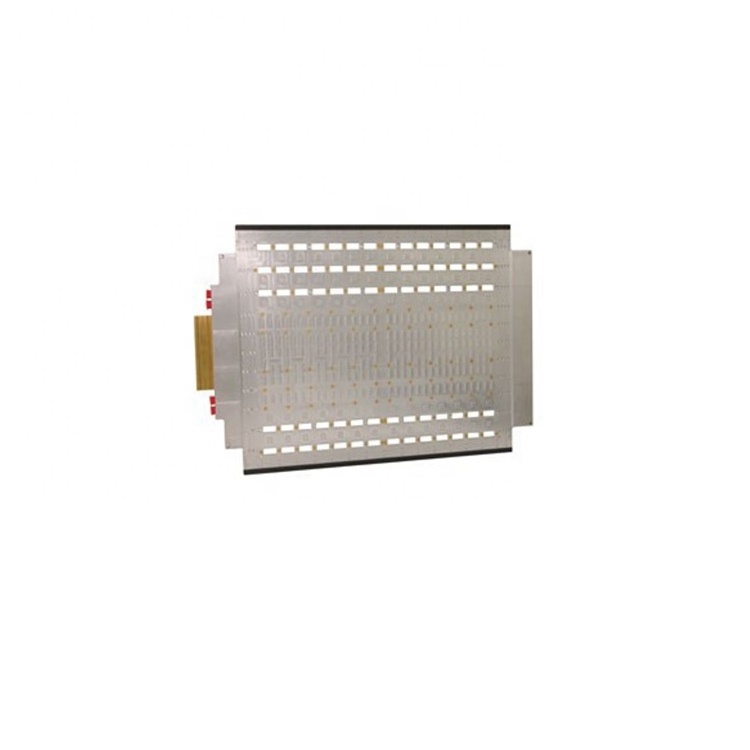

OEM Vacuum Brazed Water Cooling Plate

Features

*Efficiency exceed 90%.

*

Thermal control technology.

*

100% burn-in under ambient temperature up to 45 degree centigrade.

*

100% high voltage test under AC 1.5KV 10MA 3Sec.

Application:

Power Electronics, Military & Aerospace, Medical Lasers & Diagnostic Equipments, Industrial Lasers, Cabinet Cooling, Semiconductor Equipments, Telecommunications, Transducers.

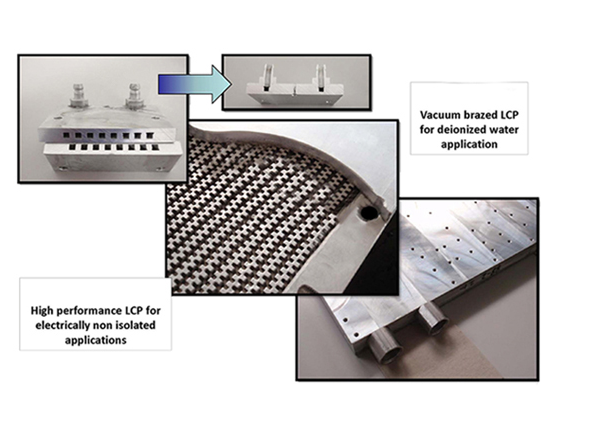

We have the ability to design flow channels, thermal simulations, and thermal designs.

Simulation software: ANSYS FLUENT.

Analog simulation brief

Analog simulation example

Left image shows Solution Grid View analysis

Analog simulation example

Right image shows Surface temperature analysis

Metalli's brazed water liquid cooling cold plate are highly reliable and leak free. We manufacture and pressure test your custom cold plates to ensure they meet your working pressure requirements. We also comply with lot traceability and provide an ultrasonic inspection record upon request. For the most efficient and cost effective brazed cold plates, choose Metalli.

Advantages of vacuum brazing

●

There are good safe production conditions:

vacuum brazing does not use flux, which significantly improves the corrosion resistance of the product, eliminating the need for various pollution and pollution-free processing equipment.

●

Reduced production costs:

vacuum brazing saves a lot of expensive metal flux and does not require complex flux cleaning processes.

1.How can I get quotation and feedback for my products?

Provide your requirements and send to e-mail.

2.How long can I get the quotation?

Normally, we can provide instant feedback and then provide quotation within 48 hours.

3.How long will you produce the parts?

Production lead time for CNC machining is 1-4wks, according to difference products and quantity. We will communicate with Customers on production plan and delivery for each PO.

4.What's your payment terms?

1) Especially for new customers: T/T in advance or 50% T/T in advance, left needs to be wired before delivery.

2) L/C

5.Incoterms:

1) EXW or FOB Shanghai, is preferred;

2) CIF

6.Shipment:

By Air or Sea.

7.Will you sign NDA?

Yes, NDA is necessary between us.