- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

WULIN

-

Model Number:

-

WL-FSB

-

Voltage:

-

380-450V

-

Dimension(L*W*H):

-

14000*6000*2400MM

-

Weight:

-

15000 KG

-

Marketing Type:

-

New Product 2021

-

Application:

-

Supermarket

-

Type:

-

Multi-Function Packaging Machine

-

Suitable material:

-

Filter Paper

-

Color:

-

Customer Requirement

-

Speed:

-

30-180 pcs/min

-

Product name:

-

Manufacturer for Automatic High Speed Paper Carry Bag Making Machine

-

After Warranty Service:

-

Video technical support

-

After Service:

-

Spare parts

-

Warranty Service:

-

Field maintenance and repair service

-

Certification:

-

CE

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Paper

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

WULIN

-

Model Number:

-

WL-FSB

-

Voltage:

-

380-450V

-

Dimension(L*W*H):

-

14000*6000*2400MM

-

Weight:

-

15000 KG

-

Marketing Type:

-

New Product 2021

-

Application:

-

Supermarket

-

Type:

-

Multi-Function Packaging Machine

-

Suitable material:

-

Filter Paper

-

Color:

-

Customer Requirement

-

Speed:

-

30-180 pcs/min

-

Product name:

-

Manufacturer for Automatic High Speed Paper Carry Bag Making Machine

-

After Warranty Service:

-

Video technical support

-

After Service:

-

Spare parts

-

Warranty Service:

-

Field maintenance and repair service

-

Certification:

-

CE

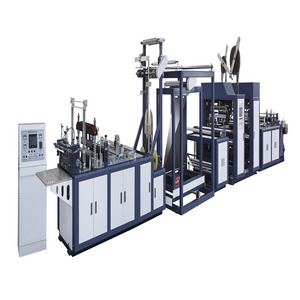

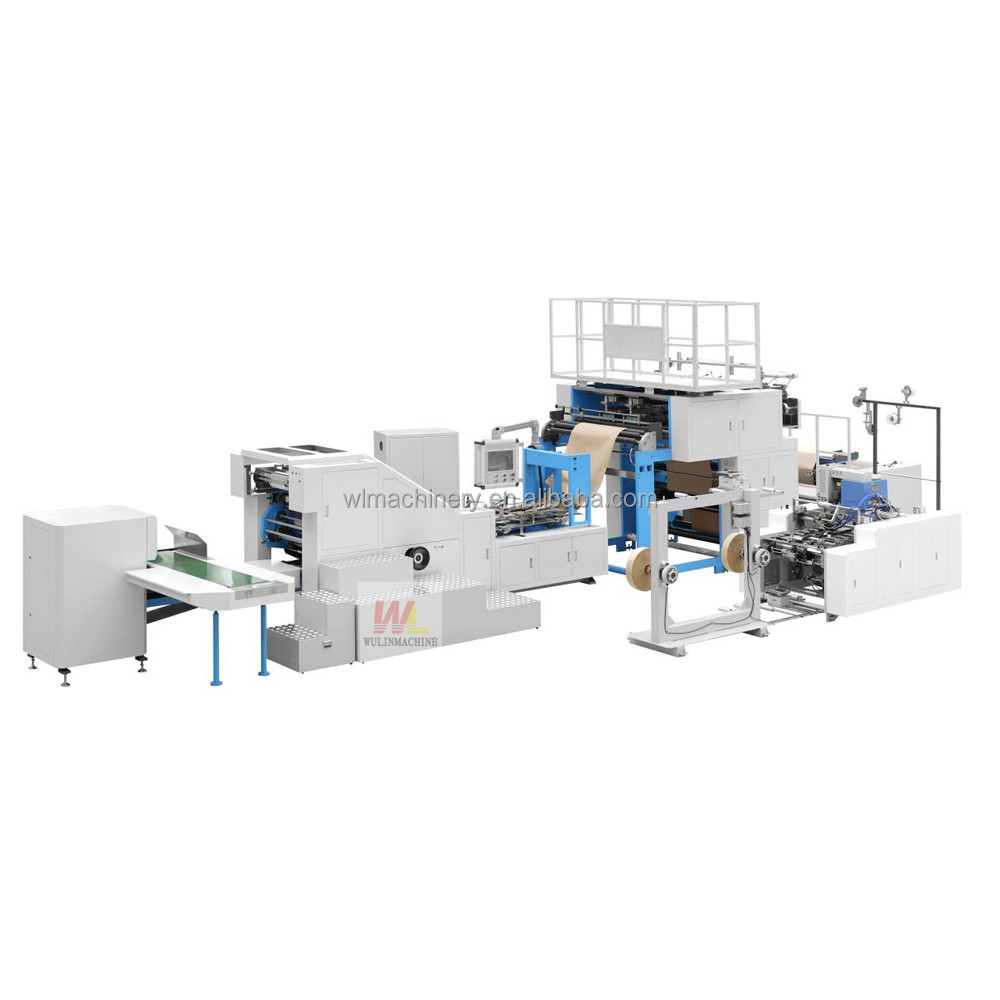

Product Overview

Fully automatic square bottom paper bag machine is used to produce hand-held paper bags with hand handles. This machine is especially suitable for the bulk production of shopping bags in food and clothing industries. The machine by hand holding machine will roll of rope and paper roll system arm in arm, arm in arm through the transmission system to put the unit will be primary or printed roll paper twine again a preliminary point break, patch glue, automatic paste hand wan, again by the host with a hand holding the paper to the edge glue, into the bottom of the cone, cutting, creasing, glue, bag forming and piped out of the bag, The whole process is done simultaneously at once. This machine adopts Japanese Mitsubishi imported high speed motion controller (CPU), through the high speed bus control servo operation, to ensure stable movement, smooth motion curve, is the majority of printing and packaging manufacturers preferred automatic portable square bottom paper bag equipment.

FEATURES AT A GLANCE

1.Willon touch screen man-machine interface

2.Japanese original Mitsubishi motion controller

3.Japanese Mitsubishi servo motor with German SICK photocell

4.Hydraulic dynamic lifting structure for raw material loading and unloading

5.Brushless servo motor for raw material correction

Right elevation

Vertical

elevation

Front elevation

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

|

|

1

|

Cutting Length

|

270-530mm

|

|

|

|

2

|

Cutting Length(total)

|

270-430mm

|

|

|

|

3

|

Paper Bag Width

|

120-330mm

|

|

|

|

4

|

Paper Bag Width(total)

|

200-330mm

|

|

|

|

5

|

Bottom Width

|

60-180mm

|

|

|

|

6

|

Paper gsm

|

60-150g/㎡

|

|

|

|

7

|

Paper gsm(total)

|

80-150g/㎡

|

|

|

|

8

|

Material Width

|

380-1050mm

|

|

|

|

9

|

Material Width(total)

|

570-1050mm

|

|

|

|

10

|

Paper Material Diameter

|

1300mm

|

|

|

|

11

|

Paper Core Inner Diameter

|

76mm

|

|

|

|

12

|

Handle Patch Length

|

152mm

|

|

|

|

13

|

Handle Patch Width

|

50mm

|

|

|

|

14

|

Paper Rope Spacing

|

75mm

|

|

|

|

15

|

Paper Handle Rope Diameter

|

3-5mm

|

|

|

|

16

|

Handle Patch Paper Roll Width

|

100mm

|

|

|

|

17

|

Handle Paper Roll Diameter

|

1200mm

|

|

|

|

18

|

Handle Patch Paper Weight

|

100-135g/㎡

|

|

|

|

19

|

Mechanical Speed

|

30-200pcs/min

|

|

|

|

20

|

Paper Bag Production Speed

|

30-180pcs/min

|

|

|

|

21

|

Handle Speed

|

30-150pcs/min

|

|

|

|

22

|

Cutter Method

|

Pinking

|

|

|

|

23

|

Total Power

|

380V/ 3Phase 4Line 41.5kw

|

|

|

|

24

|

Total Weight

|

15000Kg

|

|

|

|

25

|

Machine Overall Dimension

|

14000*6000*2400mm

|

|

|

PRODUCT CONFIGURATION

SALES AND SERVICE NETWORK

Successful Project

Project in Thailand

Project in India

Project in Russia

SIMILAR PRODUCTS

FAQ

We promises that all machines made by us come with services of repair and replacement.

Machine warranty is 12 months. We provide free repair services to any failures caused by us within warranty time. However wearing parts are not included.

1. Any quality failure problems happens within guarantee period, we will reply within 2 hours after receiving your request.

2. We will provide lifelong maintenance service to all parts

3. We will handle any quality failure occurred within warranty time.

4. We will provide lifelong technical support started from using of the machine.

5. We will supply normal parts within warranty period to ensure better user experience. Parts supply will be charged after warranty period.

Machine warranty is 12 months. We provide free repair services to any failures caused by us within warranty time. However wearing parts are not included.

1. Any quality failure problems happens within guarantee period, we will reply within 2 hours after receiving your request.

2. We will provide lifelong maintenance service to all parts

3. We will handle any quality failure occurred within warranty time.

4. We will provide lifelong technical support started from using of the machine.

5. We will supply normal parts within warranty period to ensure better user experience. Parts supply will be charged after warranty period.

Hot Searches