- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

13000*2100*2100

-

Weight (KG):

-

7000

-

Power (kW):

-

6

-

Applicable Industries:

-

Petrochemical, Chemical

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Maximum capacity:

-

6000kg/hr,5000kg/hr,4000kg/hr

-

Diameter of particle:

-

3~6mm

-

Height of particle:

-

1.5~1.8mm

-

Width of machine:

-

2100mm,1800mm,1600mm,1200mm

-

Length of machine:

-

13M

-

Packaging machine:

-

yes

-

Weight:

-

7000kg

-

Power(W):

-

10KW

-

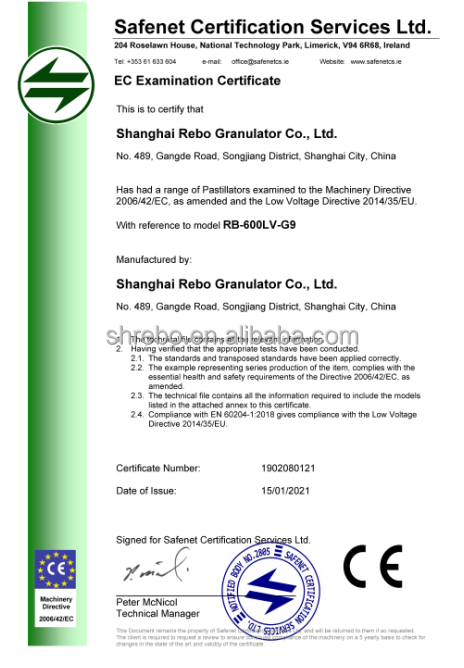

Certification:

-

SINOPEC and CE certificate

Quick Details

-

Output (kg/h):

-

5000

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Rebo

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

13000*2100*2100

-

Weight (KG):

-

7000

-

Power (kW):

-

6

-

Applicable Industries:

-

Petrochemical, Chemical

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Maximum capacity:

-

6000kg/hr,5000kg/hr,4000kg/hr

-

Diameter of particle:

-

3~6mm

-

Height of particle:

-

1.5~1.8mm

-

Width of machine:

-

2100mm,1800mm,1600mm,1200mm

-

Length of machine:

-

13M

-

Packaging machine:

-

yes

-

Weight:

-

7000kg

-

Power(W):

-

10KW

-

Certification:

-

SINOPEC and CE certificate

Sulfur Pastillator

Product introduction:

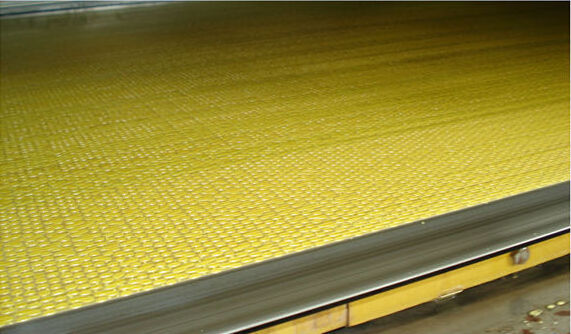

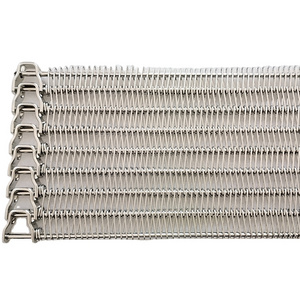

The liquid sulfur is fed by means of a jacket pump from the storage tank to the drop former by jacket piping. These piping are heated by steam. The pastillating unit consists of a drop-former and a steel belt cooler. The drop former is designed according to the Sharp patented for REBO and consists of stator which is supplied with liquid product and a perforated rotating outer shell which turns concentrically around the stator depositing sulfur drops across the whole belt width. circumferential speed of the drop former is synchronized with the speed of the belt cooler. The drops are therefore deposited on the belt without deformation and, after solidification, result in regular pastilles with an optimum shape. The heat released during solidification and cooling is transferred by the stainless steel belt to the cooling water indirectly. This is sprayed against the belt underside, collected in tanks, and returned to the re-cooling plant, In no phase the cooling water gets in contact with the sulfur. At the cooler end the pastilles are taken off with a discharge knife and pass via chutes to a bagging system. The diameter of pastilles is about 3-6mm and its height is about 1.5-1.8mm. The width of the complete machine is 1200mm,1600mm,1800mm and 2100mm and its length is 13m. The output of single machine is 1500kg/hr, 3000kg/hr, 4000kg/hr and 6000kg/hr. It can be matched with semi-automatic or full-automatic packing machine to complete automatic packing and stacking.

Product advantages:

*The maximum capacity of single machine reaches up to 6000kg/hr;

*The sharp nozzle type patent technology, there are thousands rows of sharp nozzle hole on the surface of outershell;

* The innovation technology based on the introduction and ingestion of Germany granulator technology;

* The sole equipment is put into operation in the sulfur industry at the earliest in China;

* The sole company in the domestic has passed united technology assessment by SINOPEC technology development center and the introduced major equipment domestication office, belonging to ministerial appraisal;

*The service life of steel belt is long, sulfur pastillse is plump, and with good flowability;

*The cooling water and product not contacting mutually, cooling water is not polluted by product;

*All large-scale oil refinery project with tens of millions of tons in the domestic adopt Rebo machine;

*Successfully renewed 30 imported Germany machines, and 3 American machines, with a total of 33;

* Easy operation, less wearing parts, low operation cost, stable quality and low fault rate;

* Continuous steel belt and equipment overall package ensure that steel belt does not deviate and damage V rope;

Main achievements: 1. ZRCC; 2. Qingdao refinery; 3. Gaoqiao Petrochemical; 4. Hainan refinery; 5. Duzishan refinery; 6. Guangxi Qinzhou refinery.

Packaging & Shipping:

For orders overseas, we use suitable package method to adapt situation of sea transportation or trains transportation. Anyhow, we will disassemble the machine as per sea or train's transportation way, use containers to ship. The key parts of the machine will be packed with Non-fumigation wooden cases. Other parts such as the big frame are packed with plastic film.

Technical service:

We will always provide our sincere customers lont-term technical service no matter within the warranty time or not. After the machine arrives at site and the situation of guidance can meet, we will dispatch our engineers to go to the site for providing the technical guidance service to help customers to install, start-up and commission the machine. During the period of installation, commissioning and starting-up, our engineers will be responsible to handle in any problems caused and also help customers to train operating stuff . For exceed warranty technical service, customers can ask us any time. We also assure that we supply spare parts and technical updation for our customers.

Company information:

Shanghai Rebo Granulator Co., Ltd is manufacturer specializes in Research and production of pastillator. We are very honored to own Mr. Yang Haibo who had worked at Sandvik of Germany and other experts of powder industry. We have been awarded 30 items National Patents including 5 items Invention Patents with proprietary intellectual property rights. Since the establishment in March, 2000, our company has developed and grew rapidly with principle: Quality for Survival, Management for Benefit, Technology for Development. We always insist the strategy of integrated Research, Production, Sales& Service in the process of development.