- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

150kw

-

Dimension(L*W*H):

-

30*20*5m

-

Type:

-

reciprocating or roller type

-

Raw material:

-

waste paper

-

Application:

-

producing kinds of trays

Quick Details

-

Production Capacity:

-

5000-6500pcs

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Pantao Machinery

-

Voltage:

-

220V/380V

-

Power:

-

150kw

-

Dimension(L*W*H):

-

30*20*5m

-

Type:

-

reciprocating or roller type

-

Raw material:

-

waste paper

-

Application:

-

producing kinds of trays

Products Description

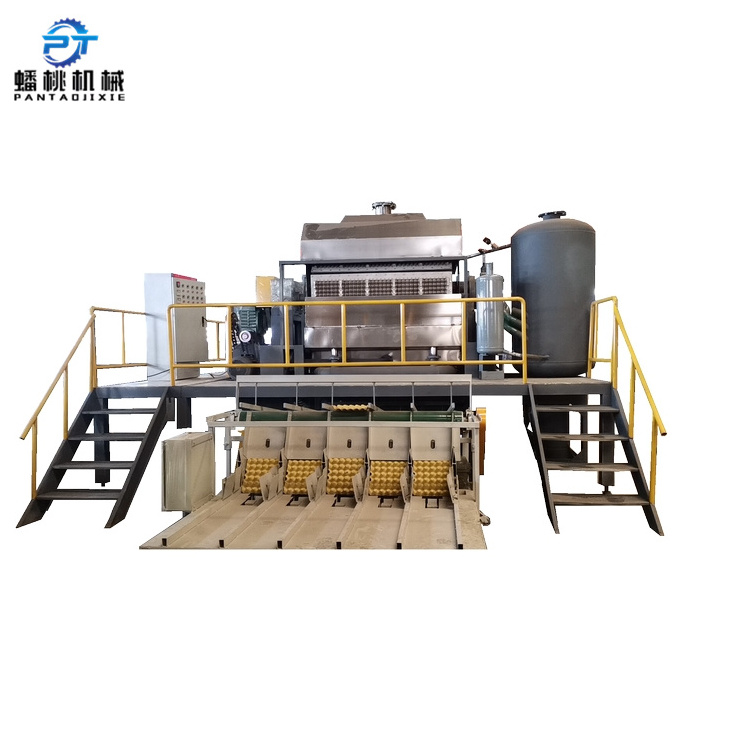

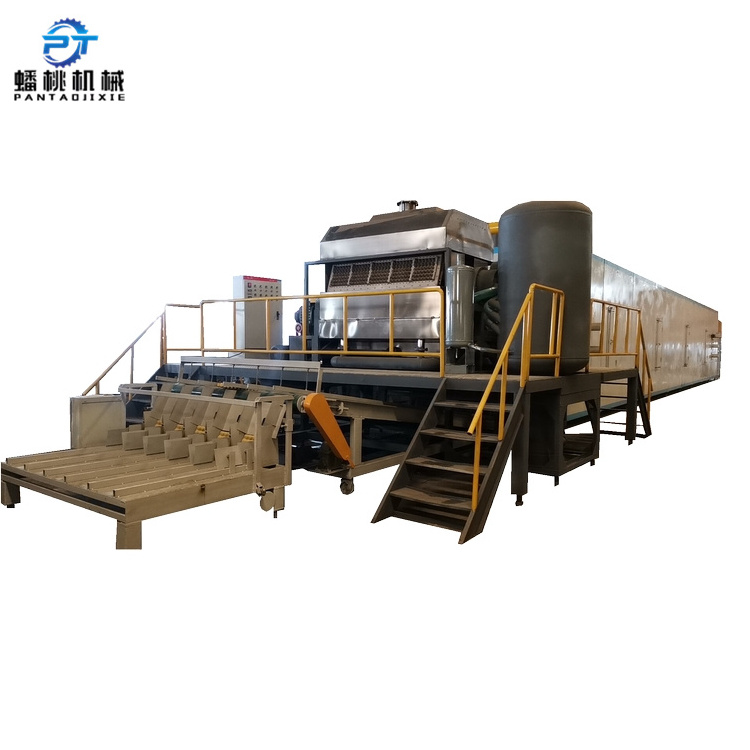

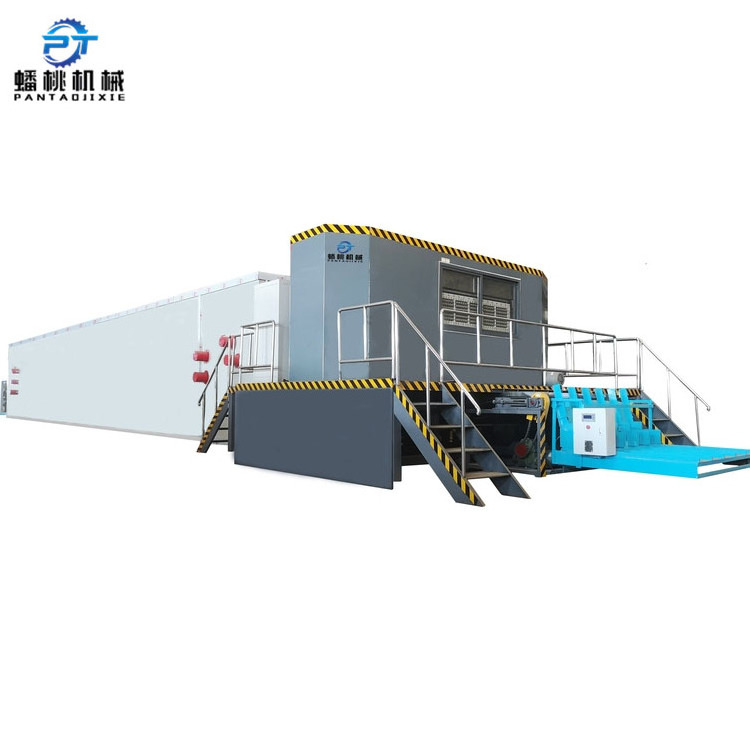

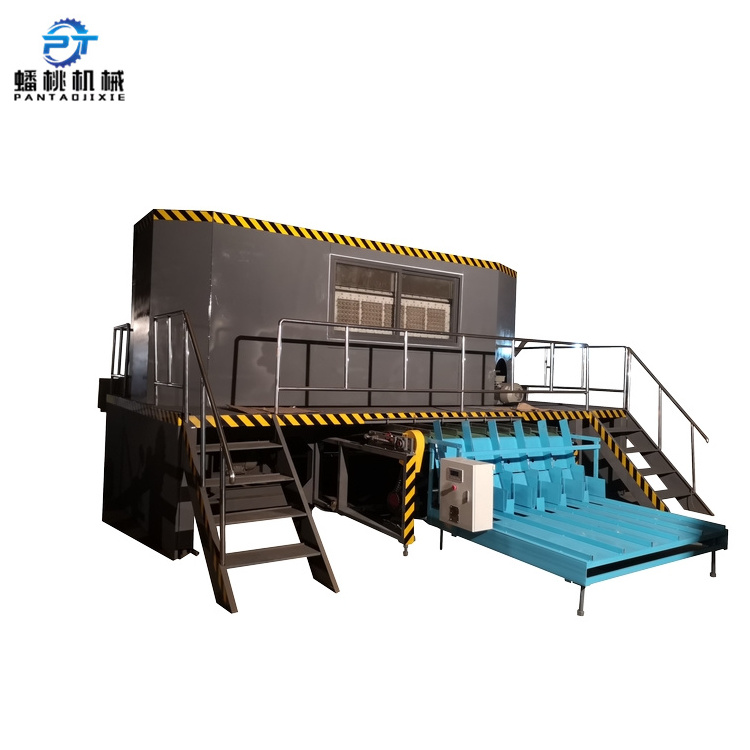

Introduction of Egg Tray Production Line

Egg Tray Machine uses waste paper as raw material and it can produce different kinds of products according to your requirements, such as egg trays/dishes, egg cartons/boxes, fruit trays, coffee cup trays, industrial packages, electrial lining packing trays and so on. The different final products are decided by your market choice.

The egg tray machine moulds can be designed and made as customers’ requirement with samples.

The egg tray machine moulds can be designed and made as customers’ requirement with samples.

The production process flow :

Pulping system→Forming(Molding) system→Drying system→Packing system

Working Process

Pulping: It is the process of mixing the raw materials with water. Then you can get the slurry that is dried to form the egg trays

.

Pulping system→Forming(Molding) system→Drying system→Packing system

Working Process

Pulping: It is the process of mixing the raw materials with water. Then you can get the slurry that is dried to form the egg trays

.

Molding:

The process is that using negative pressure and vacuum absorption turn the slurry to egg trays. You can make egg trays, egg boxes, apple trays and so on with the egg tray machines by changing different moulds.

Drying:

It basically involves drying the wet semi-finished products by using egg tray drying line. Good drying process can lead to minimal losses of poorly-formed trays. There are metal and brick egg tray drying line.

Packing:

With packing machine, we can squeeze large amounts of egg trays into together. Thereafter, egg trays will be packaged in the desired way. Also, it is convenient for conveying egg trays after packing.

Flow chart

Consumption

|

Model

|

Capacity

(pcs/hr) |

Mould quantity

|

Paper

(kg/hr) |

Water

(kg/hr) |

Electricity

(kw/hr) |

|

YZ-F500

|

600

|

1*2+2

|

40

|

120

|

33

|

|

YZ-F1000

|

1000

|

1*3+3

|

85

|

255

|

33

|

|

YZ-F1500

|

1500

|

1*4+4

|

100

|

300

|

42

|

|

YZ-F1700

|

1700

|

1*5+5

|

119

|

357

|

50

|

|

YZ-4X2000

|

2000-2500

|

3*4+3

|

170

|

510

|

57

|

|

YZ-4X3000

|

2500-3000

|

4*4+4

|

212

|

636

|

60

|

|

YZ-4X4000

|

3500-4500

|

4*5+5

|

200

|

600

|

60

|

|

YZ-4X5000

|

4500-5500

|

4*6+6

|

220

|

660

|

65

|

|

YZ-8X4000

|

4000-5000

|

4*8+4

|

380

|

1140

|

129

|

|

YZ-8X5000

|

5000-6000

|

5*8+5

|

425

|

1275

|

150

|

|

YZ-8X6000

|

6000-7000

|

6*8+6

|

459

|

1377

|

153

|

|

YZ-8X8000

|

8000-10000

|

8*8+8

|

500

|

1500

|

200

|

|

YZ-12X6000

|

5500-6500

|

5*12+5

|

425

|

1275

|

178

|

|

YZ-12X7000

|

7000-7500

|

6*12+6

|

490

|

1470

|

245

|

Successful projects

Sales manager: Aileen Zhang

Wechat/WhatsApp:+86 15631142207

Email:yazhong01@yazhongpulpmolding.com

Hot Searches