- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*200*60 mm, 400*200*200 mm, Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Donyue

-

Voltage:

-

220v/380v/415v,any

-

Dimension(L*W*H):

-

1350*1460*1800mm

-

Weight (KG):

-

4500 kg

-

vibration force:

-

30-50kn

-

moulding period:

-

15-20s

-

weight:

-

4.5t

-

pallet:

-

no need

-

block type:

-

main hollow and solid blocks

-

Raw material can be used:

-

sand/flasash/cement/stone/water

-

power type:

-

electric

-

block 400*200*200 capacity:

-

720-960pcs/hour

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine

-

Brick Raw Material:

-

CONCRETE

-

Production Capacity (Pieces/8 hours):

-

5760 pcs/8hours, 12000 pcs/8hours, 360-480pcs/hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*200*60 mm, 400*200*200 mm, Other

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Donyue

-

Voltage:

-

220v/380v/415v,any

-

Dimension(L*W*H):

-

1350*1460*1800mm

-

Weight (KG):

-

4500 kg

-

vibration force:

-

30-50kn

-

moulding period:

-

15-20s

-

weight:

-

4.5t

-

pallet:

-

no need

-

block type:

-

main hollow and solid blocks

-

Raw material can be used:

-

sand/flasash/cement/stone/water

-

power type:

-

electric

-

block 400*200*200 capacity:

-

720-960pcs/hour

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Video technical support

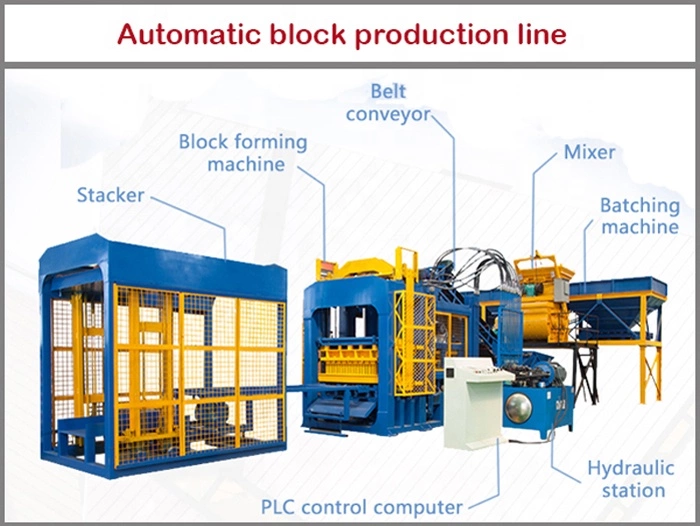

Best selling automatic line QT4-15 with PLC control

JD500 Pan Mixer

Host machine

sizes of hollow bricks, solid bricks, paving bricks and curb stones can be produced

PLC control cabinet .

stability of machine operation

Stacker

Hydraulic station

One set of free moulds

Each workshop has its own function, such as cutting material workshop,welding and heat treatment workshop, assembling workshop, commissioning and debugging workshops, to ensure to complete any projets efficiently and carefully.

Advanced production equipments, arc welding, carbon dioxide welding machine, gas cutter, carburizing treatment , large stamping machine, many lathes, wire-electrode cutting etc. to ensure every finished machines with higher quality and longer using life.

1).QT4-15 automatic block laying machine can realize the automatic production of a full set of production lines

2).SIEMENS motor ,heated treated mould,firm and durable.

3).QT4-15 brick machine can make hollow block and soild block paver block ect

4).less investment,more production.

5).ISO9001/CE/SGS certificationm: +8619863994533(whatsapp,wechat)

1.Control PLC: we select original Japan Mitsubishi PLC combine with independently develop machine control program, assure stable and high efficiency working status.

2.The motor for the host machine is Germany SIEMENS brand or ABB brand

3. The switch will use France Schneider brand and Japan Omron

4. Mould: newest heat treatment device and carburizing treatment will assure longer mould life span and ensure the strength of mould reach to 54-58 HRC so that the mould can be used more than 100 thousand times .

Raw material percent

- 1. 8-10% cement, 30-40 % sand , 50-60% crushed stone.

- 2. 8-10% cement, 30% flyash, 60% sand or stone powder

2. Mixing Section: After being mixed evenly with water, raw material are unloaded to the block making machine through belt conveyor.

3.Block forming Section: Mixed raw material are then sent to the mould case. Under PLC computer intelligent control. Hydraulic transmission, vibration, shaping takes place.

4.Automatic Stacker Section: After demoulding ,green brick will be unloaded to the bamboo pallet.

5.Block Curing Section : Wet product will be conveyed through green block conveyor then to the stacker.

Pre-sale

(1) Professional suggestions (raw material matching, machine selection, planThe condition of building factory, feasibility analysis for brick machine production line)

(2) Device model choice (recommend the best machine according to the raw material, capacity

and the size of brick)

(3) 24 hours on-line service

(4) Welcome to visit our factory and production line anytime,if you need, we can Make inVitation

card for you.

(5) Introduce the company file, product categories and production process.

In-Sale

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product acceptance

(4) Shipping on time

After-sale

(1) The engineer will guide to carry out the plant at the clients side if needed.

(2) Set up, fix,and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time,keep well communication with each other

Why chose Dongyue Machinery Group?

1. Dongyue group is the top 3 of block machine industry.

2. We use GB Q235 steel which should be through carburizing heat treatment for the moulds, which will prolong the machine life span for at least 5 years.

3. Timely and effective after-sales service

1) If you'v got a brick factory and you want to improve your current formual and save the cost, our professional team are willing to give you the best suggestion and technical support.

2) If you want to join in this filed, our professional team would like to offer you the best guidance and give you a full appreciation about our machine and the the feasibility of its investment.

3) If you are doubt about your raw material or whether it could be formed as a perfect brick. Don't be worry about that. Just contact us. Send your local material to us by post. We can offer you the test for free. We firmily believe that any kinds of resonable raw material could be a useful one with the help of our machine.

5. Our company have offices in Indonesia, Vietnam and India, our clients are across the whole world.