- Product Details

- {{item.text}}

Quick Details

-

Filling capacity:

-

500BPH based on 1L

-

Filling Accuracy:

-

99~99.5%

-

Function:

-

Fill viscous liquid into container

-

Bottle shape:

-

Round and rectangular bottle and square bottle

-

Filling range:

-

0.1-1L, 0.2-2L, 0.3-3L, 0.5-5L, 1-5L according to client's need

-

Filling concept:

-

Filling with piston controlled by PLC

-

Feature:

-

Servo motor control piston, high precision filling level

-

Machine type:

-

4 nozzle filling machine

Quick Details

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Composite, PET, PP, PE, HDPE

-

Model:

-

EFL-P400

-

Number of filling nozzles:

-

4 Nozzles

-

Filling capacity:

-

500BPH based on 1L

-

Filling Accuracy:

-

99~99.5%

-

Function:

-

Fill viscous liquid into container

-

Bottle shape:

-

Round and rectangular bottle and square bottle

-

Filling range:

-

0.1-1L, 0.2-2L, 0.3-3L, 0.5-5L, 1-5L according to client's need

-

Filling concept:

-

Filling with piston controlled by PLC

-

Feature:

-

Servo motor control piston, high precision filling level

-

Machine type:

-

4 nozzle filling machine

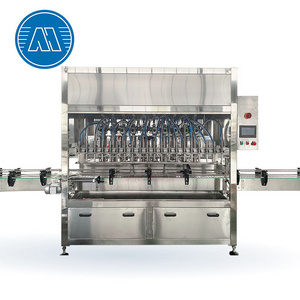

Factory Supply 4 Nozzle Sweetened Condensed Milk Curd Bottle Fillign And Capping Machine / Liquid Yogurt Filling Line

EZIO-EFL liner type

Yogurt Filling Machine

started since beginning, bottle unscrambler, bottle cleaning, product filling, bottle capping, labeling, till end of line wrapping, sealing, packaging. It's a fully automatic system only need a supervisor to watch complete line automatic working. Well saved client's labor cost and highly improved production efficiency. There are many models can fill various sizes of container from 50ml-5000ml, EFL models are able to handling various viscosity product from fluid to viscous product.From company established to today, EZIO's EFL piston filling system has been serving for condiments, mayonnaise, sauce, fruit paste, mas, edible oil, lubricant, cosmetics, cream, honey, e-liquid, essentials, hand washer, shampoo and more industry.

Features of automatic filling machine

1) High quality pIston filling concept is applicable for low-high viscous product.

2) Servo motor control piston working to ensure the highly precised filling level.

3) All material is made of high quality stainless steel 304 or 316L, depending on client's product.

4) Fully automatic control system to save labor cost from long term prospect

5) Ezio's perfect installation service and after sale service making sure production fast setup and less downtime.

Features of milk filling machine

6) High intelligence HMI interface, operator can adjust fill level, fill speed and other functions directly throuh touch screen of milk bottle filling machine.

7) Variable filling level to adapt to many size container, suffice cient's multiple needs.

8) Various filling applications, EFL yogurt bottle filling machine servces all kinds of industry including food, chemistry, cosmetic, medicine and more.

9) Can perfectly working with upstream and downstream equipments such as turnable, bottle unscrambler, depalletizer, bottle washing machine, inkjet printer, labeling machine, packaging machine, tunnel pasteurizer and more.

What determined the EFL piston filling machine's capacity?

What determined the EFL piston filling machine's filling range?

The piston size and volume determine a piston filling machine's filling range.The bigger piston you build, the higher filling volume. But not means you could fill small volume bottle by a big volume piston. For example, a 5L volume piston only can fill 500ml-5000ml bottle, you couldn't make it to fill 100ml bottle as well. So before build the machine, Ezio's engineer must confirm all the requirment with client to avoid future's trouble.

Send us an inquiry, our sales engineer will talk to you in detail.

Non-dripping filling nozzles

This work aimed to invent a liquid filling valve that does not drip after closing. Breaking the traditional design concept, the filling valve was designed to be composed of two cavities, the filling cavity and the negative suction cavity, and the negative suction cavity was within the filling cavity.

Highly precised piston pump

The machine works by one principle; The piston is drawn back in its cylinder so that the product is sucked into the cylinder. A rotary valve then changes position so that the product is then pushed out of the nozzle instead of back into the hopper. The volume of the product that is sucked into the cylinder is the precise volume that will be dispensed into the container. All these procedure is highly controlled by servo motor to assure 100% working stability.

Servo motor driving assurance

Reliable pneumatic valve

Control signal to the solenoid valve an instruction, solenoid valve open, compressed air into the air chamber, pneumatic valve to drive the valve membrane, and then push the stem, the stem to open or close the valve heart! start or finish pumping. The pneumatic control valve is composed of an actuating mechanism and an adjusting mechanism. The actuating mechanism is a thrust component of the regulating valve, which generates the corresponding thrust according to the pressure of the control signal.

Temperature preserve during filling

Some product is very senstive to temperature changing, in order to minimize the affect for product during entire filling process, we will make all pipes and piston pumps insulation with outside.For this special process client should let Ezio's engineer know the product's character before build machine.

Bottom up filling for highly viscous product

Some product has high viscosity, it's hard to achieve right dispension for filling nozzles.Product will be messy in the bottle because it couldn't be dispensed spread. So Eziomachinery will make filling heads filling from bottom to up. With the action of whole filling head and partented valve opener design to achieve high quality filling.

Infeed turnable

A group of bottles is placed onto the table's ready to infeed. Bottles are then pushed onto the rotating table and delivered to the EZIO-EFL system.These bottles will begin to enter the exit lane of the feed table and travel onto the main feed conveyor in a single file. Those bottles that do not enter the exit lane travel around the table and accumulate against the bottle return assembly. This process is continuously repeated when bottles are in demanded. Rectangular bottle will be different design sctructure.

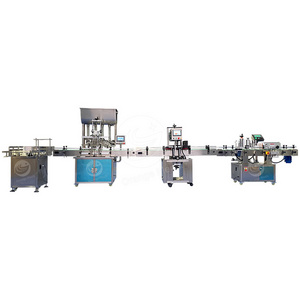

Capping machine & Sealing system

System include

<1>Cap unscrambler

<2>Cap elevator

<3>Cap loader

<4>Capping machine

Suitable for

<1>Plastic thread cap <2>Lug cap for twist off bottle

<3>Ropp aluminum cap

<4>Crown cap <5>Special cap

Foil seal closing machine

Electromagnetic induction aluminum foil sealing machine with double cooling system, suitable for tropical, subtropical regions or the need for continuous use of the region, can seal the container mouth.

When a metal foil is close to the sensor head, eddy current is generated on the aluminum foil, and the degree of heating is determined by the intensity of the eddy current, the frequency and the length of the action time.

Carton palletizer

The high level palletizer is suitable for cartons, plastic crates, shrink wrapped packs and five gallon bottles etc palletizing.With inspection device to check the storage of cartons on conveyor and regulate the speed according to inspection data. With safety device to stop machine and alarm in emergency.

EZIO sticker labeling system

<1>Round bottle one label.

<2>Rectangular bottle two label double side.

<3>Rectangular bottle one label multiple side.

<4>Square bottle two label double side.

<5>One label multiple side.

<6>Neck and bottle body labeling.

<7>Neck and bottle body labeling tapered.

<8>Customization for special container and label.

EZIO sleeve shrinking machine

<1> Heat shrink sleeve labeling machine.

<2> OPP Hot melt labeling machine.

<3> PVC label stick labeling machine.

It adopts double driving structure ,that is four-wheel driving, self-centering and balanced pressure of four wheels. It can achieve the good effect of transmission of labels smoothly, stably and rapidly.

EZIO pe film shink wrapping machine

<1> PE film/Half-tray shrink wrapping machine.

<2> Carton box packaging machine.

It adopts the photoelectric sensor to detect online, gather signals which are controlled by PLC, and adopts piston as executable element, to realize product conveying, combination, film wrapping, cutting, heat& shrink, cool and finally get the finished product.

Learn about Ezio Machinery for curd filling machine

Ezio Machinery Co., Ltd always focuses on the

designing and manufacturing

of reliable, quality, and innovative

processing equipment, filling equipment and packaging equipment.

Quality assurance is our key to success. In manufacturing equipment, we make no compromise in quality. We only use the high-precision machinery tools to manufacture our components.

<1> Welcome all client from all over the world come to our

3000M2 factory

for a visit.

<2> We have many types of

manufacuring centers

like water jet cutter, plasma cutter, laser cutter, CNC machine to assure the quality from root.

<3> Since establish to today, Ezio has always own more than

30 invention patents

and various equipment certifications such as

ISO9001:2001; CE Certificate , SGS , COC , TUV.

<4> Our engineer team is always avaliable for

overseas installation, commissioning, training

work for our client.

<5> We have suffcient

spare parts in stock

can delivery at any time to customer to less downtime.

<6> All the equipment will be

tested and run for 24 hours before leaving the factory

, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechanical stability.

<1>Company & Facility tour for yogurt filling and capping machine

Ezio welcome customers from all over the world to visit our working facilities, watch our actual production and negotiate order in detail. Customers only need to inform Ezio's sales consultant in advance of your arrival time, arrive airport/rail way station. We will pick you up to our company when you arrive in China.

<2>On-site installation service for 4 nozzle filling machine

Ezio will provide customers with overseas installation services. Our professional team of engineers is always available for installation trip. Customers need to make an installation appointment with Ezio company in one week advance. Ezio will communicate with client and arrange a reasonable installation date according to the actual situation. Customer must inform Ezio company in advance if there is any changes on schedule.

<3>On-site commissioning service for yogurt filling line

Ezio's team of engineers will apply a visa to client's country in one month advance, and client should assist Ezio's engineers to get visa by issuing a formal invitation. Ezio's engineers will depart at the time communicated by both side and complete the installation and commissioning work within the estimated time.

<4>On-site training service for sweetened condensed milk filling machine

Ezio will provide customer with professional technical training course includes equipment concept, structure, function explanation and maintenance, equipment control and operation, precautions, etc.

<5>Customization service

Ezio's engineering team is able to customize filling and capping equipment for client, as long as client provide us with detailed sample including product, container and specific requirement.

Why Choose Ezio Machinery for Factory Supply 4 Nozzle Sweetened Condensed Milk Curd Bottle Fillign And Capping Machine / Liquid Yogurt Filling Line

1.Over 90% parts come from one source

Over 90% of components are manufactured by Ezio to ensure consistent quality. The remaining parts are imported from top-quality suppliers in Taiwan and Italy. Ezio monitors and controls the quality of our parts and can supply our clients with spare parts promptly.

2.Focus on strict QC process

Before the equipment is delivered, it will undergo a series of tests including operational testing, electrical testing, environmental testing and etc. Our equipment has to meet and exceed our rigorous quality standard before shipping.

3.Attention on Customer Satisfaction

Ezio aims to meet the ongoing demand of our clients with innovative approaches. Our professional service staff and engineers actively work with clients to come up with the solution to tackle different client requests.

4.Emphasis on Innovation

Ezio recognizes innovation is the key to improve product function and client experience. Ezio replaces complicated, cumbersome construction of the traditional design with modern and creative design to construct machine that are easier to operation and maintain.

5.Focus on continuous improvement

Ezio has an advanced internal control system and governance structure to ensure that the company is managed efficiently and effectively. Our dedicated and professional employees are the most valuable assets of our firm.

6.Advanced Order Tracking System

Ezio sales consultants provides real time order updates for our clients. Our clients can track the detai ls of the production and ensure the whole process is error-free.