Our company is located in Yixing, Jiangsu Province, China. Established in 2007, Holly Technology is a domestic forerunner in producing environmental equipments and parts used for sewage treatment.

Nowadays, our company has developed into a comprehensive enterprise integrating production, trading, design and installation

service of sewage treatment equipments.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

According to your order

-

Size:

-

According to your order

-

Weight (KG):

-

500 kg

-

Model:

-

HLSS

-

Screen Width:

-

500-2400mm

-

Screen Length:

-

1800mm

-

Device Width:

-

640-2540mm

-

Function:

-

Solid Liquid Separation

-

Installation Angle:

-

45°~75°

-

Certification:

-

ISO

-

Feature:

-

Easy Operation

-

Processing:

-

Industry Wastewater

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Holly

-

Material:

-

Wooden case, Stainless Steel

-

Weight:

-

According to your order

-

Size:

-

According to your order

-

Weight (KG):

-

500 kg

-

Model:

-

HLSS

-

Screen Width:

-

500-2400mm

-

Screen Length:

-

1800mm

-

Device Width:

-

640-2540mm

-

Function:

-

Solid Liquid Separation

-

Installation Angle:

-

45°~75°

-

Certification:

-

ISO

-

Feature:

-

Easy Operation

-

Processing:

-

Industry Wastewater

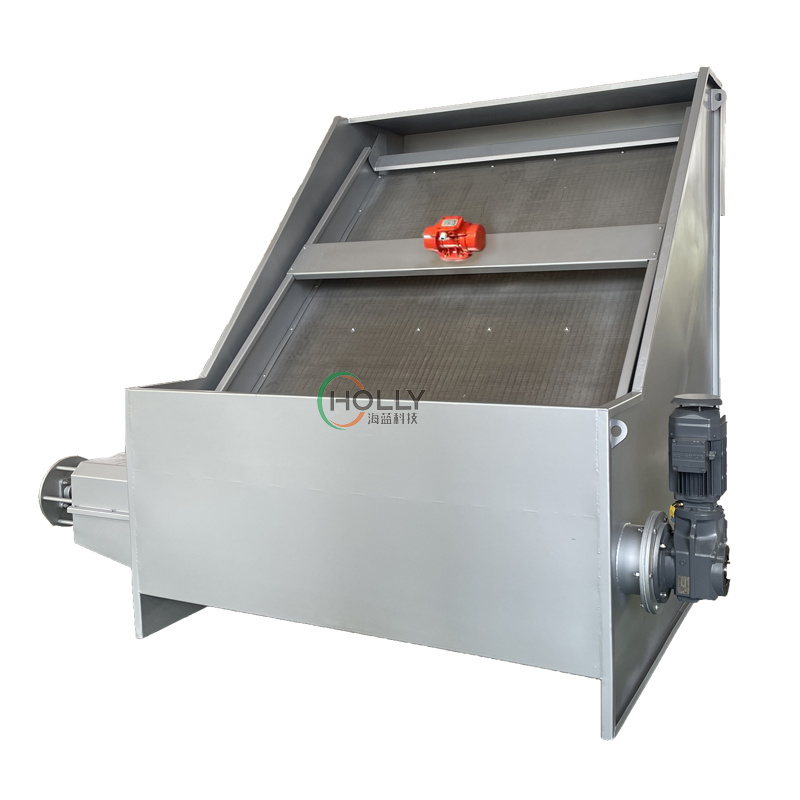

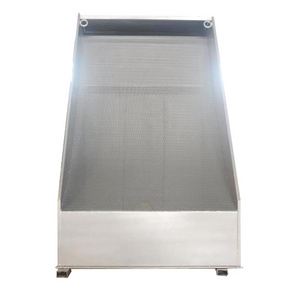

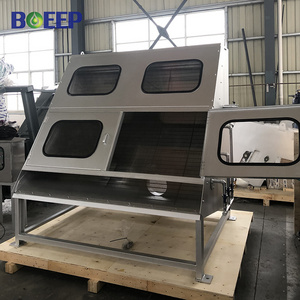

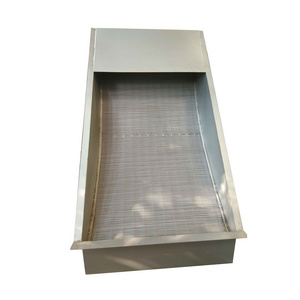

Static screen is a small non-powered separation equipment used to filter suspended solids, floating solids, sediments and other solid or colloidal substances in sewage treatment or industrial wastewater treatment. A wedge-shaped seam welded stainless steel screen is used to make an arc screen surface or a flat filter screen surface. The water to be treated is evenly distributed to the inclined screen surface through the overflow weir, the solid matter is intercepted, and the filtered water flows from the screen gap. At the same time, the solid matter is pushed to the lower end of the sieve plate to be discharged under the action of hydraulic power, so as to achieve the purpose of separation.

Static screen can effectively reduce suspended solids (SS) in water and reduce the processing load of subsequent processes. It is also used for solid-liquid separation and recovery of useful substances in industrial production.

1.The filter parts of the equipment are made of seam welded stainless steel screen plates, which have the characteristics of high mechanical strength, no deformation, no cracking, etc.;

2.Use the gravity of the water itself to work without energy consumption;

3.It is necessary to manually flush the grid seams from time to time to prevent being blocked;

4.The equipment does not have the ability to resist shock loads, and the processing capacity of the selected model should be greater than the maximum flow.

The main body of the static screen is a stainless steel arc-shaped or flat filtering screen surface made of wedge-shaped steel rods. The waste water to be treated is evenly distributed on the inclined screen surface through the overflow weir. Due to the small and smooth surface of the screen, the gap on the back is large. The drainage is smooth and not easy to be blocked; the solid matter is intercepted, and the filtered water flows out from the gap of the sieve plate. At the same time, the solid matter is pushed to the lower end of the sieve plate to discharge under the action of hydraulic force, so as to achieve the purpose of solid-liquid separation.

|

Model&

Descriptions

|

HLSS-

500

|

HLSS-

1000

|

HLSS-

1200

|

HLSS-

1500

|

HLSS-

1800

|

HLSS-

2000

|

HLSS-

2400

|

|

Screen Width

(mm)

|

500

|

1000

|

1200

|

1500

|

1800

|

2000

|

2400

|

|

Screen Length

(mm)

|

1800

|

1800

|

1800

|

1800

|

1800

|

1800

|

1800

|

|

Device Width

(mm)

|

640

|

1140

|

1340

|

1640

|

1940

|

2140

|

2540

|

|

Inlet DN

|

80

|

100

|

50

|

150

|

200

|

200

|

250

|

|

Outlet DN

|

100

|

125

|

200

|

200

|

250

|

250

|

300

|

1. Papermaking wastewater—recycle fiber and remove solids.

2. Tannery wastewater—removes solids such as fur and grease.

3. Slaughter Wastewater—Remove solids such as pouches, fur, grease, and feces.

4. Urban domestic sewage—Remove solids such as fur and debris. 5. Alcohol, starch factory wastewater-remove plant fiber shells, groceries and other solids

6. Wastewater from pharmaceutical factories and sugar factories—removal of solids such as various waste residues and plant shells.

7. Wastewater from beer and malt factories—removes solids such as malt and bean skin.

8. Poultry and livestock farms—removal of solids such as livestock hair, feces and sundries.

9.Fish and meat processing plants—removal of solids such as offal, scales, minced meat, grease, etc. Others such as the pre-treatment of sewage from chemical fiber plants, textile plants, chemical plants, plastic processing plants, large machinery plants, hotels, and residential communities.

Yixing Holly Technology CO., LTD.

Hot Searches