- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

2.25

-

Weight (KG):

-

4000

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Doshine

-

Dimension(L*W*H):

-

3*2*2.2m

-

Voltage:

-

220V/380V

-

Power:

-

2.25

-

Weight (KG):

-

4000

Product Overview

Application

All kinds of raw wood logs, tree branches, solid wood products from the wood processing factories, All kinds of raw bamboo materials, All kings of crops waste as corncob,cotton sticks , All kinds of nutshell as hazelnut shell, macadamia shell, cashew nut shell. All kinds of tropical fruits hard shell as palm shell, coconut shell, And all the biomass machine made briquettes from sawdust,peanut shell,rice husk,crops straw,sunflower seeds shell,sugarcane,vinasse,etc.

FEATURES AT A GLANCE

Vertical Hoist Carbonization Furnace

1.No pollution: No smoke and dust discharge, wood tar and wood vinegar are recycled and treated by purification system.

2.Energy saving:1000kg charcoal just need 30kg firewood or 15kg liquid gas for heating.

3.High productivity: time saving by three inner pots recycled working . Reducing the cooling time 2/3.

4.High Efficiency: the carbonizing rate up to 99%

5.Easy Operation labor saving: Easy for loading and unloading , we will send some steel basket for you to load the wood and keep the good look of the final charcoal and we will use the hoist to put the steel basket with wood into the furnace inner pot.

6.Small investment less area taken: only with water and electricity can go to production.

7.High quality product: high carbon content percentage of the final charcoal, spark-less, long burning time,odorless,low ash,good looks

Horizontal Airflow Carbonization Furnace

1.The furnace body is designed in three layers, and the furnace door is equipped with flame-retardant insulation cotton, which has good airtightness, good heat preservation and fuel saving

2.Equipped with flue gas recovery device to save fuel

3.Advanced flue gas purification device to achieve smokeless emission

4.Kiln car design, saving labor and convenient operation

5.Large loading capacity, one-time carbonization

6.Various heating methods, available with wood, coal, natural gas

7.Equipped with water cooling system, cooling speed is fast, high efficiency

PRODUCT SPECIFICATIONS

|

Horizontal Airflow Carbonization Furnace

|

|

|

||

|

Model

|

DS3000

|

DS45000

|

||

|

Volume(CBM)

|

5.3

|

8.0

|

||

|

Stove inner Size(m)

|

Diameter1.5 * length 3.5

|

Diameter1.5 * length 4.5

|

||

|

Stove outer size(m)

|

Diameter 2.1 * length 3.5

|

Diameter2.1 * length 5

|

||

|

Capacity(kg/ day)

|

800-1000

|

1200-1500

|

||

|

Vertical Hoist Carbonization Furnace

|

|

|

|

|

||||

|

Model

|

Power (kw)

|

Capacity (kg/day)

|

Machine size (m)

|

Weight (t)

|

||||

|

DS01

|

2.25

|

1500-2000

|

3*2*2.2

|

4.1

|

||||

|

DS02

|

2.25

|

3000-4000

|

6*2*2.2

|

8.2

|

||||

|

DS03

|

7.7

|

5000-6000

|

9*2*2.2

|

12.3

|

||||

|

DS04

|

7.7

|

6000-8000

|

12*2*2.2

|

15.8

|

||||

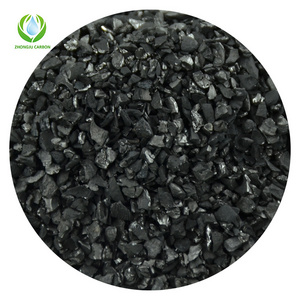

Final product pictures

Packing and shipping pictures

Working Principle

FAQ

1.What is the main material of this machine ?

It used to carbonize wood branches, wood logs, bamboo, coconut shell blocks, biomass rods and scrap pieces in furniture factories,etc.

2.What is the finished product?

The finished product can be the original wood charcoal, coconut shell charcoal, bamboo charcoal and biomass briquettes charcoal,etc.

3.The application area of the finished product?

It is generally use for home heating, barbecue, cooking, activated carbon factory reprocessing, etc.

4.What is the output per day of the horizontal airflow carbonizing furnace?

We have a variety of models to meet the needs of different customers.We have a capacity of 3-15 cubic meters, and the output ranges from 1 ton to 5 tons per day.

5.What are the main features of this carbonization furnace?

The carbonization stove is a new designed machine, It adopts the advanced carbonized technology heat flow, carbonized rate increased significantly, The carbonized rate is 99%. And the operation is very convenient, good safety, high production

efficiency, can save a lot of energy, good environmental protection performance.

It used to carbonize wood branches, wood logs, bamboo, coconut shell blocks, biomass rods and scrap pieces in furniture factories,etc.

2.What is the finished product?

The finished product can be the original wood charcoal, coconut shell charcoal, bamboo charcoal and biomass briquettes charcoal,etc.

3.The application area of the finished product?

It is generally use for home heating, barbecue, cooking, activated carbon factory reprocessing, etc.

4.What is the output per day of the horizontal airflow carbonizing furnace?

We have a variety of models to meet the needs of different customers.We have a capacity of 3-15 cubic meters, and the output ranges from 1 ton to 5 tons per day.

5.What are the main features of this carbonization furnace?

The carbonization stove is a new designed machine, It adopts the advanced carbonized technology heat flow, carbonized rate increased significantly, The carbonized rate is 99%. And the operation is very convenient, good safety, high production

efficiency, can save a lot of energy, good environmental protection performance.

Hot Searches