- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Xrido

-

Voltage:

-

220V/380V/415V/600V or customized

-

Dimension(L*W*H):

-

2900(L)X1360(W)X2120(H)

-

Weight (T):

-

25000

-

Name:

-

Waste Palstic Crushing

-

Keyword:

-

Double Shaft Scrap Metal Recycling

-

Final product:

-

1-10 Cm

-

Color:

-

Customized Color

-

Advantage:

-

High Efficiency Low Energy Consumption

-

Capacity:

-

300-22000 Kg/hour

-

Kw:

-

22

-

Type:

-

Environment-friendly

-

Material Processed:

-

PE Film PP Woven Bags

-

Lifetime:

-

5~10 Years

Quick Details

-

Max.Production Capacity (kg/h):

-

10000-15000

-

Place of Origin:

-

Henan, China

-

Production Capacity (kg/h):

-

8000 - 10000 kg/h

-

Brand Name:

-

Xrido

-

Voltage:

-

220V/380V/415V/600V or customized

-

Dimension(L*W*H):

-

2900(L)X1360(W)X2120(H)

-

Weight (T):

-

25000

-

Name:

-

Waste Palstic Crushing

-

Keyword:

-

Double Shaft Scrap Metal Recycling

-

Final product:

-

1-10 Cm

-

Color:

-

Customized Color

-

Advantage:

-

High Efficiency Low Energy Consumption

-

Capacity:

-

300-22000 Kg/hour

-

Kw:

-

22

-

Type:

-

Environment-friendly

-

Material Processed:

-

PE Film PP Woven Bags

-

Lifetime:

-

5~10 Years

Products Description

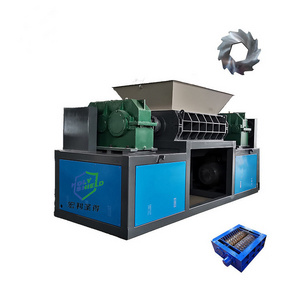

The rolling shear type shredder is used for double single axis roller crushing structure and is specially designed for handling various soft materials. Rolling shear shredder is mainly used for shredding film, woven bags, tons of bags,plastic bags, fishing nets,fabrics,textiles,fibers and other soft materials.

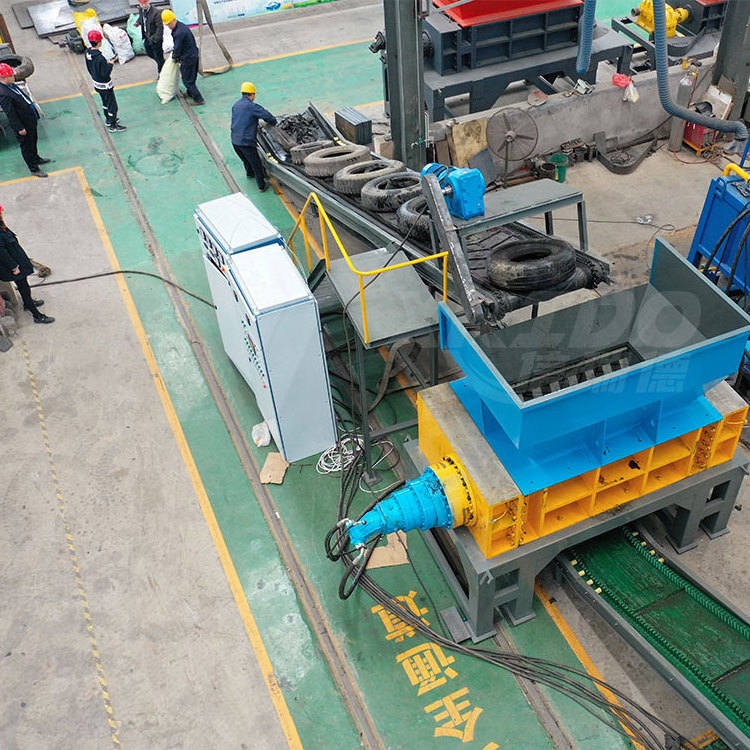

double shaft steel scrap wire cars tire

metal shredders

crushing plastic crusher machine price

Main Application

The

double shaft shredder

knife structure is specially designed for the winding materials, which can effectively solve the problems of the traditional double-shaft shredder winding the shaft, connecting the knife,and clipping the material,and greatly improving the crushing efficiency and the quality of the finished product.The material enters the crushing chamber and the high-speed rotating blade and the fixed blade cooperate with each other to achieve tearing and cutting to achieve the crushing effect. The centering knife prevents the material from becoming entangled or even with a knife. The STAGE STAGE3 broken material falls through the screen,and STAGE2 then enters the next processing step through the conveying equipment.

1. Double uniaxial roller design, no shaft, no knife, no material,the material is more broken.

2. Knife shaft can be reversible material can be broken to increase the broken output.

3. Quartet body,four cutting edges can be used interchangeably,and the use cost is low.

4.The gap between the fixed knife and the movable knife can be adjusted, and the discharge size can be controlled as required.

5. Unique cutting type design, the baling materials can be broken directly without unpacking.

Product Paramenters

|

Model

|

Size (mm)

|

Inlet size (mm)

|

Blade Thickness (mm)

|

Weight (kg)

|

|

RDS-80

|

1600*1225*1850

|

400*480

|

10

|

1500

|

|

RDS-100

|

2800*1300*1850

|

500*480

|

20

|

2200

|

|

RDS-120

|

3000*1300*1850

|

800*480

|

20

|

2500

|

|

RDS-140

|

3300*1900*2200

|

1000*690

|

40

|

5200

|

|

RDS-160

|

3600*2000*2200

|

1200*690

|

40

|

6400

|

Recommend Products

Automatic baling press horizontal baler machine

automatic baling press used horizontal baler machine is the mechanical and electrical integration, the very high degree of automation of the packing machine, mainly by the mechanical system, control system, feeding system and power System and so on.The whole packing process is composed of pressure package, back haul, suitcase, turn box, out of bag, out of bag and package.

Customer Photos

Certifications

Hot Searches