- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GOORUI

-

Model Number:

-

GHBH 022 36 2R9

-

Product name:

-

WTP/ETP/STP aeration air blowers

-

Frequency:

-

50Hz

-

Rated Power:

-

16.5kW

-

Rated Voltage:

-

345-415/600-690Y (V)

-

Rated Current:

-

35.0/20.0Y (A)

-

Max Airflow:

-

1110m³/h

-

Max Vacuum:

-

-410mbar

-

Max Pressure:

-

370mbar

-

Sound:

-

74db(A)

-

Weight:

-

197kg

Quick Details

-

Application:

-

Industrial Blower

-

Pressure:

-

High Pressure

-

Warranty:

-

2 years

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

GOORUI

-

Model Number:

-

GHBH 022 36 2R9

-

Product name:

-

WTP/ETP/STP aeration air blowers

-

Frequency:

-

50Hz

-

Rated Power:

-

16.5kW

-

Rated Voltage:

-

345-415/600-690Y (V)

-

Rated Current:

-

35.0/20.0Y (A)

-

Max Airflow:

-

1110m³/h

-

Max Vacuum:

-

-410mbar

-

Max Pressure:

-

370mbar

-

Sound:

-

74db(A)

-

Weight:

-

197kg

Products Description

|

Product Name

|

Aeration Ring Air Blowers used in Sewage/Effluent/Waste Water Treatment Plants

|

|

|

|

|||

|

Features

|

100% Copper Wire Motor, High Quality Bearings, Low Noise,

Energy-saving,

Big Airflow, More Duable, More Safety.

|

|

|

|

|||

|

Model

|

GHBH 022 36 2R9

|

|

Frequency

|

50Hz

|

|||

|

Stage

|

double

|

|

Phase

|

three

|

|||

|

Rated Power

|

16.5kW

|

|

Rated Voltage

|

345-415△/600-690Y (V)

|

|||

|

Rated Current

|

35.0△/20.0Y (A)

|

|

Max Airflow

|

1110m³/h

|

|||

|

Max Vacuum

|

-410mbar

|

|

Max Pressure

|

370mbar

|

|||

|

Sound

|

74db(A)

|

|

Weight

|

197kg

|

|||

|

High efficiency motor;

IP55 & Insulation class H;

Built-in Thermal Protector(PTC); High Temperature-Resistance bearing; Special customized blower and OEM available; 24 months warranty and long-term technical support; CCC, CE, SGS, TUV, RoHS, ISO9001 certification approved. |

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

|

|

|

|

|

|

||||

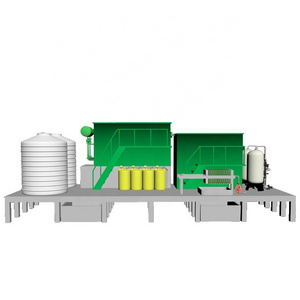

The aeration tanks in wastewater treatment plants are activated with oxygen by using compressed air. A thorough mixing of the sludge with oxygen increases the gas yield and reduces its retention time in the tank. Blower or low pressure screw compressor technologies can be found in fish process wastewater treatment plants.

INSTRUCTIONS

1. It should be placed in a relatively stable place, and the surrounding environment should be clean, dry and ventilated.

2. The direction of rotation of the impeller must be consistent with the direction of the pointed tip marked on the fan cover.

3. When working, the working pressure should not be greater than 8 kPa, so as to avoid excessive heat generation of the air pump and damage to the air pump caused by motor overcurrent.

4. It is strictly forbidden for solid, liquid and corrosive gas to enter the pump body.

5. The filters and silencers at both ends of the air inlet and outlet should be cleaned in time according to the situation to avoid clogging and affecting use.

6. The external connection of the air inlet and outlet must be connected by a hose (rubber tube, plastic spring tube).

PRECAUTIONS

1. Flat washers and spring washers must be used to tighten the screws.

2. It is best to use rubber buffer rubber to bear the weight of the vortex air pump, especially the high-power vortex air pump, which is indispensable.

3. For some occasions that require noise, a silencer can be installed to reduce the noise (generally down, about 5 dB), the silencer is installed at the end of the inlet duct or outlet duct.

4. For some occasions with high requirements for noise, you can add a layer of silencer cotton according to the conditions of the machine itself to meet the noise requirements on site. For details, please consult our customer service.

5. When using silencing cotton to silence the sound, pay attention to the distance between the vortex air pump and the box, pay attention to the ventilation and heat dissipation of the vortex air pump, and pay attention to using rubber cushioning to bear the weight of the vortex air pump. According to the picture, you need to consult customer service.

6. The air inlet and outlet of the vortex air pump For pipe connection, hose connection should be used to isolate vibration.

Product packaging

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches