- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HAOLONG

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

Various

-

Weight (KG):

-

400

-

Power (kW):

-

2.2

-

Name:

-

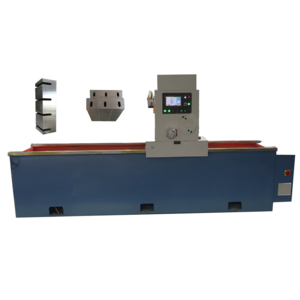

Automatic Straight Blades grinding Sharpener Chipper Knife

-

Product name:

-

Powerful Grinder

-

Application:

-

Grind Rail Surface

-

Max. Grinding Diameter:

-

800mm

-

Usage:

-

Surface Polishing

-

Max. Grinding Length:

-

700-1500mm

-

Keywords:

-

Standard Knife Grinder

-

After-sales Service Provided:

-

Online support

-

Certification:

-

NONE

Quick Details

-

Wheel Size(mm):

-

135

-

Year:

-

2020

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HAOLONG

-

Voltage:

-

380V 50HZ

-

Dimension(L*W*H):

-

Various

-

Weight (KG):

-

400

-

Power (kW):

-

2.2

-

Name:

-

Automatic Straight Blades grinding Sharpener Chipper Knife

-

Product name:

-

Powerful Grinder

-

Application:

-

Grind Rail Surface

-

Max. Grinding Diameter:

-

800mm

-

Usage:

-

Surface Polishing

-

Max. Grinding Length:

-

700-1500mm

-

Keywords:

-

Standard Knife Grinder

-

After-sales Service Provided:

-

Online support

-

Certification:

-

NONE

Product Overview

FEATURES AT A GLANCE

The knife sharpener was originally called the end face sharpener, and its structure is mainly a gantry type. Mainly aimed at: sharpening centers, forestry industry, printing plants, paper-making plastics, book printing centers, medium-sized sharpening rooms and other institutional enterprise users.

Main types: automatic sharpener, precision sharpener, CNC sharpener, woodworking sharpener, special scraper sharpener, printing sharpener, paper cutter sharpener, multi-function sharpener, double sharpener Head sharpener, round knife sharpener, etc.

1. The design of the body of the sharpener has changed the original loose frame structure to a steel plate closed welded structure. Greatly improve the strength of the body, increase and extend its service life.

2. For the collectively welded steel plate metal material, the full vibration aging treatment process is adopted, which obviously eliminates and reduces the degree of natural deformation of the whole machine after processing.

3. In the transmission part, the original be

lt transmission is changed to rack transmission, which overcomes the unevenness of the walking speed and guarantees its reliability and stability.

4. A change to the original design with a swing angle of 30° for the grinding head of the sharpener is greater than 90°, making it easier and faster to move up and down the workpiece and replace the grinding wheel.

5. The automatic feed design is adopted when the grinding head processes the feed, which improves the degree of automation. It effectively saves the manpower and time necessary for manual feeding, and improves the labor of the operator.

Details Images

1. Put the knife on the knife table, adjust the protruding amount of the knife to about 0.5-1.0cm, the protruding amount of both ends of the knife should be the same, you can fine-tune the top wire. Turn on the magnetization switch of the electromagnetic device button to make the knife adsorb on the knife table. Adjust the position of the angle between the grinding wheel and the blade. If the blade is in contact with the grinding wheel, turn the feed handwheel to separate it.

2. Turn on the power, turn on the power switch, the machine enters the normal working state.

3. Rotate the feed hand wheel to push the blade inward slowly and uniformly until it contacts the grinding wheel. Adjust the tightness of the contact between the blade and the grinding wheel so that the grinding wheel and the blade can work well.

Product Exhibition

Recommend Products

Packing & Delivery

Ex Factory Delivery:

The device is fully calibrated prior to shipment from the factory.

In order to meet the long-distance transport. Repeatedly handling storage needs, to ensure the integrity of the safety equipment to reach the contract factories, all of the packaging equipment to secure solid, according to the national packaging standards related to the implementation of standards and design requirements.

Packing:

1.Standard wooden case.

2.Customized packaging can be available.

Shipping:

We can ship the goods to you by International Express such as DHL,UPS,TNT,EMS and so on, you can also choose the appropriate one based on your timeline and budget.

Besides, you can choose to use your own forward.

Hot Searches