- Product Details

- {{item.text}}

Quick Details

-

Model:

-

YGWG51

-

Maximum bending capacity:

-

≤51mm

-

thickness:

-

2-3.5mm

-

Bending speed:

-

4-8r/min

-

quality of bending angles:

-

9

-

Bending maximum angle:

-

200°

-

Bending minimum angle:

-

30

-

Motor Power:

-

3kw-4 poles

-

Voltage:

-

380v;50Hz

-

Weight:

-

260kg

-

Certification:

-

ce

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support, Video technical support

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YG

-

Weight (KG):

-

100

-

Model:

-

YGWG51

-

Maximum bending capacity:

-

≤51mm

-

thickness:

-

2-3.5mm

-

Bending speed:

-

4-8r/min

-

quality of bending angles:

-

9

-

Bending maximum angle:

-

200°

-

Bending minimum angle:

-

30

-

Motor Power:

-

3kw-4 poles

-

Voltage:

-

380v;50Hz

-

Weight:

-

260kg

-

Certification:

-

ce

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support, Video technical support

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

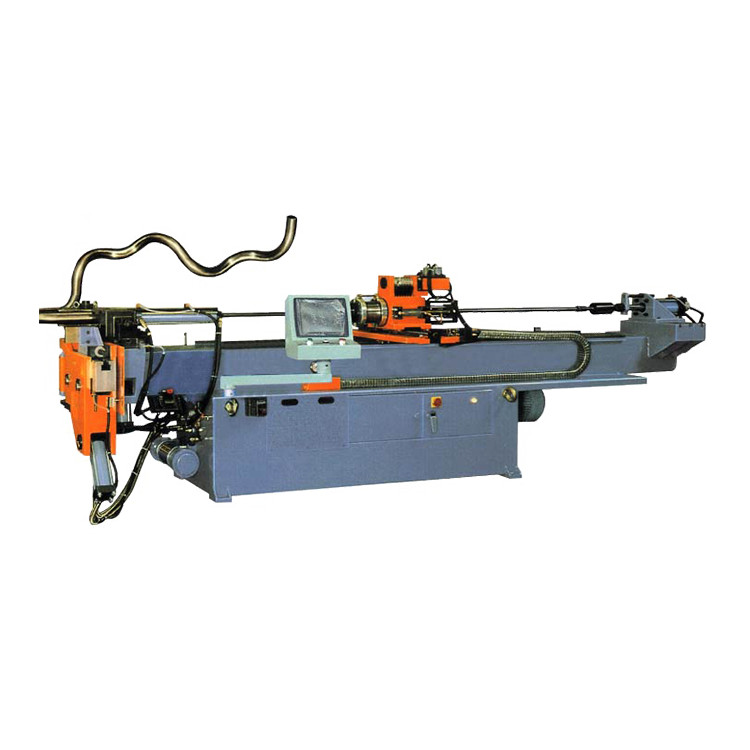

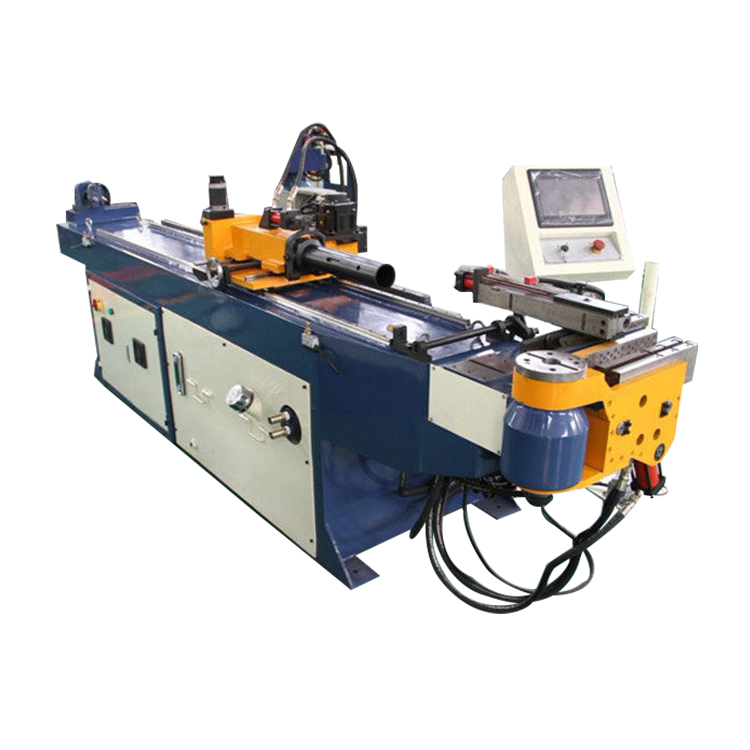

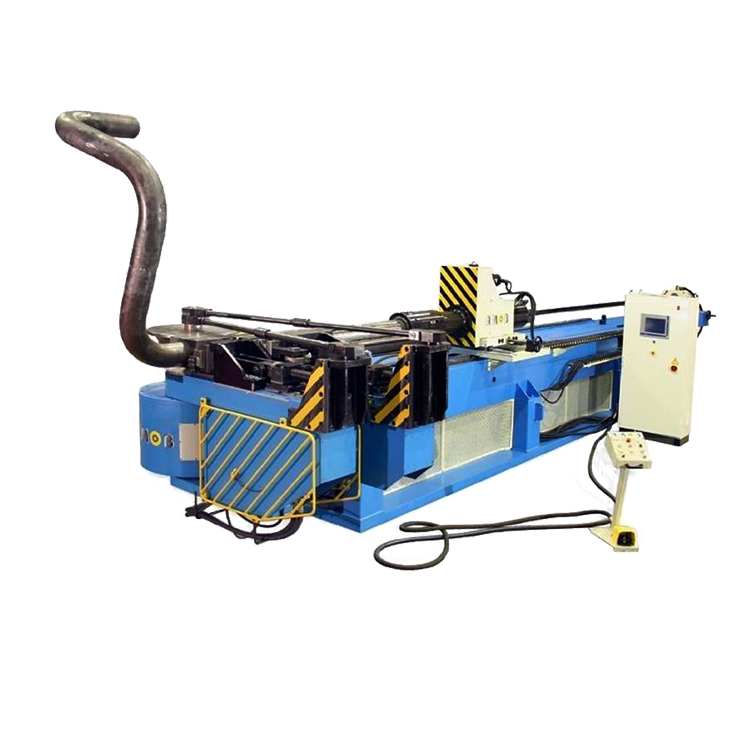

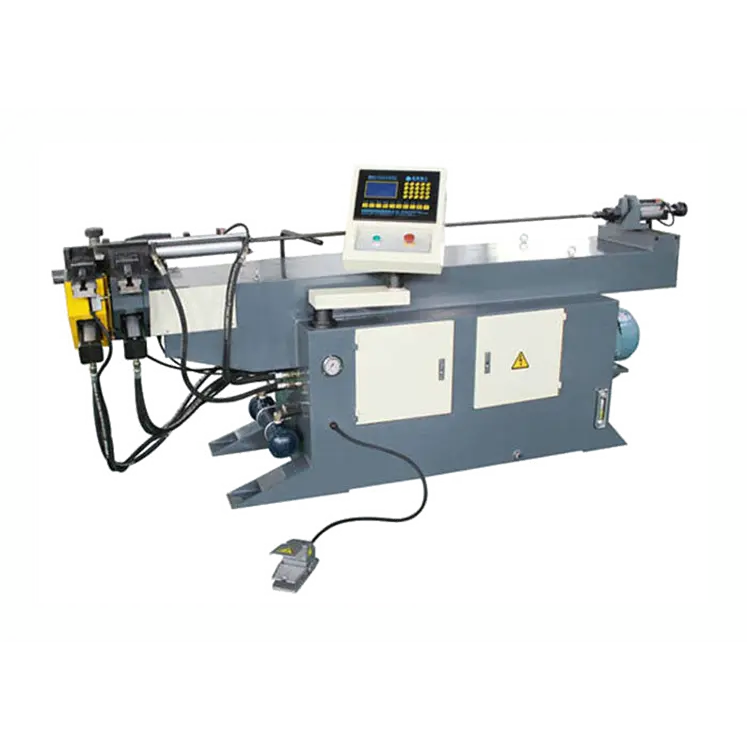

HOT SALE numerical control bending machine nissin nigeria pipe FOR

Product Detail

| Model | YGWG51 |

| Maximum bending capacity | ≤51mm |

| thickness | 2-3.5mm |

| Bending speed | 4-8r/min |

| quality of bending angles | 9 |

| Bending maximum angle | 200° |

| Bending minimum angle | 30 |

| Motor Power | 3kw-4 poles |

| Voltage | 380v;50Hz |

| Weight | 260kg |

Steel Pipe bending machine

Product Description

Range of application : Yugong C NC (Computerized Numerical Control) platform bending electric automatic pipe bending machine - Furniture manufacturing, fitness equipment, gate processing, chemical pipelines and other sectors of the large quantities of pipe processing production, mainly for steel pipe, pipe, square tube, flat tube bending arc work.

Features of the steel pipe bending machine

mechanical transmission part: the use of Turbo reducer

which is our self-made/i

ndependent research results

-

durable, strong, bending process wheel mold rotation, with high-intensity one-time shape of the pressure pipe bending. We will give you the biggest discount! Quickly call to order it! . on the sale and dealers: We will provide a complete after-sales service

2: part of the circuit control: the use of advanced embedded microcomputer intelligent control system control, angle input to digital, get started simple.

3: Product advantages:

: by the experienced professional and technical personnel production, stable performance;

: intelligent chip control, fast response, high sensitivity, intelligent control system can be set. Urgent need to use

: Encoder control angle, strong signal sensing, accurate running angle, high repeat precision, and small error.

: from the root to solve the "mechanical" control can not accurately stop the angular deviation caused by large problems. CNC bending machine electric automatic pipe bending machine

Working principle

Parameter

|

Model |

YGWG51 |

YGWG76 |

|

Maximum bending capacity |

≤Φ 51 |

Φ76x5mm |

|

thickness |

2-3.5mm |

3-5mm |

|

Bending speed |

4-8r/min |

3-5r/min |

|

quality of bend ing angles |

9 |

|

|

Bending maximum angle |

200° |

190° |

|

Bending minimum angle |

30 |

|

|

Motor Power |

3kw-4 poles |

5.5kw |

|

Voltage |

380v;50Hz |

380v |

|

Foot switch voltage |

5v

|

|

|

Dimension |

930*680*850mm |

1150x700x1000mm |

|

Weight |

260kg |

420kg |

Optional Payment Terms

1) T/T 30% deposit in advance, T/T 70% before shipment.

2) L/C at sight ( high cost, not very advise).

3) Escrow.

We accept TT, L/C ,Western Union, etc. according to which one is convenient for you!

After-sales Service

1)

Warranty time is 12 months from the date of commission, or 18 months from the factory delivery, the first shall prevail.

2

)

Special Operation and maintenance v

i

deo guide for the Customers.

3

)

Technical person work-site commission service support.We can send engineers to support you to install large sprayer machine.

4

)

Help you do worker training

5

)

On-line support 24 hours.

PACKAGE:

Standard export carton packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

1. Packaging:

1)Wrapped by protective film;

2)Packed by standard import & export wooden cases or carton boxes.

2. Shipping:

By logistics; by automobile; by train; by shipping; by air etc.