- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

410 mm

-

Width of Working Table (mm):

-

200 mm

-

Dimension:

-

4830*1780*2780

-

Place of Origin:

-

China

-

Year:

-

2024

-

Weight (KG):

-

8800

-

Motor Power (kw):

-

11 kw

-

Marketing Type:

-

Hot Product 2024

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

3200

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

410 mm

-

Width of Working Table (mm):

-

200 mm

-

Dimension:

-

4830*1780*2780

-

Place of Origin:

-

China

-

Year:

-

2024

-

Weight (KG):

-

8800

-

Motor Power (kw):

-

11 kw

-

Marketing Type:

-

Hot Product 2024

Features

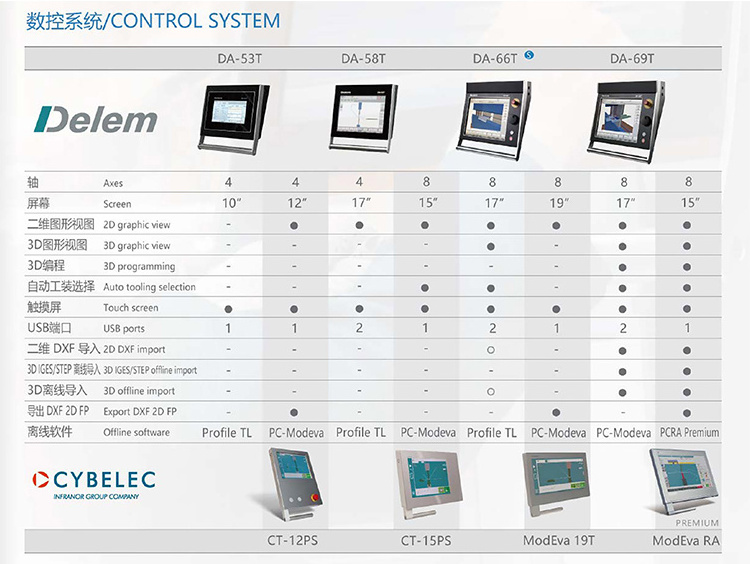

The machine is in an overall welding and overall processing structure, and the main parts of machine are all analyzed by ANSyS finite element analysis software, which has ensured the reliability of machine and the precision of entire machine. The CNC control system adopts Netherand DELEM, ltalian ESA, or SwissCYBELEC products, which can achieve the functions of graphic program-ming for bending angle, compensation for angle amendment, automatic calculation also adjustment of bending pressure, automatic calculation ofcompensation for workbench distortion, extending length of workpieces bending pressure for bottom bending,open distance, and automaticwithdrawal of rear stopper, etc.

Back gauge system

Most important feature to achieve perfect bending is the stability and the design of the back gauge, which allows an impeccable and correct product to be produced.The high speed ballscrew back gauge system mowement is also supported with linear guides, which helps the back gauge achieve long life, greater sensitivity and strengthens against any collisions.Special designed finger blocks with steps to achieve maximum stability can also be supplied for every kind of bending solution .

The machine is in an overall welding and overall processing structure, and the main parts of machine are all analyzed by ANSyS finite element analysis software, which has ensured the reliability of machine and the precision of entire machine. The CNC control system adopts Netherand DELEM, ltalian ESA, or SwissCYBELEC products, which can achieve the functions of graphic program-ming for bending angle, compensation for angle amendment, automatic calculation also adjustment of bending pressure, automatic calculation ofcompensation for workbench distortion, extending length of workpieces bending pressure for bottom bending,open distance, and automaticwithdrawal of rear stopper, etc.

Back gauge system

Most important feature to achieve perfect bending is the stability and the design of the back gauge, which allows an impeccable and correct product to be produced.The high speed ballscrew back gauge system mowement is also supported with linear guides, which helps the back gauge achieve long life, greater sensitivity and strengthens against any collisions.Special designed finger blocks with steps to achieve maximum stability can also be supplied for every kind of bending solution .

Main Technical Parameters

|

Modle

|

Normal pressure(KN)

|

Max bending width(mm)

|

Distance between uprights(mm)

|

Throat depth(mm)

|

Cylinder stroke(mm)

|

Die setting height(mm)

|

Main power(kw)

|

Oil volume(L)

|

Weight

(kg)

|

|

70T1600

|

500

|

1600

|

1300

|

205

|

100

|

540

|

5.5

|

160

|

3700

|

|

80T2500

|

800

|

2500

|

2100

|

350

|

200

|

570

|

7.5

|

225

|

5800

|

|

110T2500

|

1100

|

2500

|

2100

|

410

|

200

|

570

|

7.5

|

225

|

7800

|

|

110T3200

|

1100

|

3200

|

2700

|

410

|

200

|

570

|

7.5

|

350

|

8000

|

|

110T4000

|

1100

|

4000

|

3300

|

410

|

200

|

570

|

7.5

|

350

|

10000

|

|

135T3200

|

1350

|

3200

|

2700

|

410

|

200

|

570

|

11

|

350

|

8800

|

|

135T4000

|

1350

|

4000

|

3300

|

410

|

200

|

570

|

11

|

430

|

9800

|

|

135T5000

|

1350

|

5000

|

4100

|

410

|

200

|

570

|

11

|

550

|

15200

|

|

135T6000

|

1350

|

6000

|

4900

|

410

|

200

|

570

|

11

|

550

|

17700

|

|

175T2500

|

1750

|

2500

|

2100

|

410

|

200

|

570

|

11

|

225

|

8700

|

|

175T3200

|

1750

|

3200

|

2700

|

410

|

200

|

570

|

11

|

350

|

9800

|

|

175T4000

|

1750

|

4000

|

3300

|

410

|

200

|

570

|

11

|

430

|

12100

|

|

175T5000

|

1750

|

5000

|

4100

|

410

|

200

|

570

|

11

|

550

|

17000

|

|

175T6000

|

1750

|

6000

|

4900

|

410

|

200

|

570

|

11

|

550

|

20000

|

|

210T3200

|

2100

|

3200

|

2700

|

410

|

200

|

570

|

15

|

350

|

11500

|

|

210T4000

|

2100

|

4000

|

3300

|

410

|

200

|

570

|

15

|

430

|

13800

|

|

210T5000

|

2100

|

5000

|

4100

|

410

|

200

|

570

|

15

|

550

|

18200

|

|

210T6000

|

2100

|

6000

|

4900

|

410

|

200

|

570

|

15

|

550

|

21000

|

|

250T3200

|

2500

|

3200

|

2700

|

410

|

250

|

570

|

18.5

|

350

|

14000

|

|

250T4000

|

2500

|

4000

|

3300

|

410

|

250

|

570

|

18.5

|

430

|

16000

|

|

250T5000

|

2500

|

5000

|

4100

|

410

|

250

|

570

|

18.5

|

550

|

21200

|

|

250T6000

|

2500

|

6000

|

4900

|

410

|

250

|

570

|

18.5

|

550

|

24600

|

|

320T3200

|

3200

|

3200

|

2700

|

410

|

250

|

600

|

22

|

460

|

17700

|

|

320T4000

|

3200

|

4000

|

3300

|

410

|

250

|

600

|

22

|

460

|

20300

|

|

320T5000

|

3200

|

5000

|

4100

|

410

|

250

|

600

|

22

|

550

|

26100

|

|

320T6000

|

3200

|

6000

|

4900

|

410

|

250

|

600

|

22

|

550

|

30400

|

Hot Searches