- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZZSEGU

-

Name:

-

7 7/8 " steel teech Tricone drill bit

-

Diameter:

-

200mm

-

Surface Finish:

-

Spray Paint

-

Advantage:

-

Long Service Life

-

Feature:

-

Ultra high hardness

-

Customized:

-

Specification

-

Color:

-

Customer Required

Quick Details

-

Weight (KG):

-

35

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZZSEGU

-

Name:

-

7 7/8 " steel teech Tricone drill bit

-

Diameter:

-

200mm

-

Surface Finish:

-

Spray Paint

-

Advantage:

-

Long Service Life

-

Feature:

-

Ultra high hardness

-

Customized:

-

Specification

-

Color:

-

Customer Required

Product Description

We and our product advantages

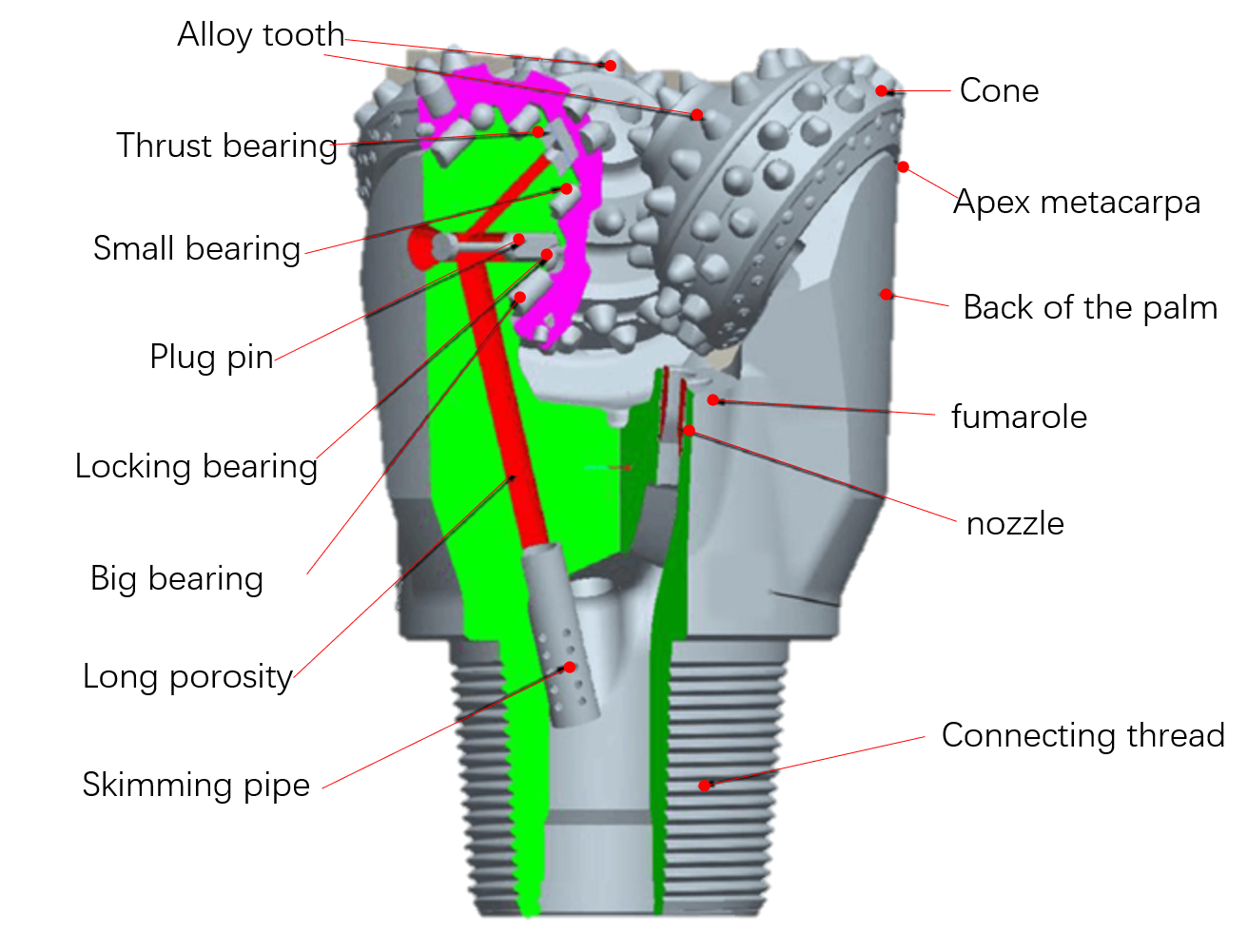

Advantages of cone bit

1.The steel tooth bit is a three-cone bit for rolling bearing oil, and the tooth surface is welded with tungsten carbide material. The bearing system can adapt to higher speed, and the drilling in the suitable formation has high mechanical speed and long service life.

2.Alloy sand is used to harden the back of the palm and the surface of the teeth, thus greatly increasing the service life of the bit;

3.The optimized tooth row number, tooth number, exposed tooth height and tooth shape give full play to the cutting ability and cutting speed of the bit;

Our company can provide specific solutions according to the actual drilling situation, customized arbitrary diameter assembly drill bits, including large caliber pile drill, special-shaped drill, reaming drill, directional drill and so on.

|

Technical parameters of steel tooth cone bit

|

|

|

|

|||

|

Applicable formation

|

Bit type

|

Bit pressure

|

Speed (RPM)

|

|||

|

Extremely soft: soft mudstone, clay, salt, etc

|

111

|

0.4-0.7

|

180-90

|

|||

|

Soft: clay, mudstone, soft sandstone, salt layer, etc

|

121

|

0.45-0.75

|

180-90

|

|||

|

Soft: clay, mudstone, soft sandstone, salt layer, etc

|

127

|

0.45-0.75

|

180-90

|

|||

|

Medium soft: shale, mudstone, sandstone, soft limestone, etc

|

131

|

0.5-0.75

|

120-60

|

|||

|

Extremely soft: soft mudstone, clay, soft sandstone, salt layer, etc

|

114

|

0.4-0.7

|

120-45

|

|||

|

Soft: clay, soft shale, mudstone, salt layer, etc

|

124

|

0.5-0.85

|

120-45

|

|||

|

Note: The recommended weight on bit and speed ranges in the table cannot be used at the same time.

|

|

|

|

|||

|

Standard for connecting threads of cone bits

|

|

|

|

|||

|

Cone bit diameter

|

|

Connecting threads

|

|

|||

|

in

|

mm

|

Rotary shoulder type external thread connection code

|

Shoulder chamfer diameter

mm(±0.4)

|

|||

|

3 1/2 - 4 1/2

|

88.9 - 114.3

|

2 3/8REG

|

78.2

|

|||

|

4 5/8 - 5

|

117.5 -127

|

2 7/8REG

|

92.5

|

|||

|

5 1/8 - 7 3/8

|

130.2 - 187.3

|

3 1/2REG

|

105.2

|

|||

|

7 1/2 - 9 3/8

|

190.5 - 238.1

|

4 1/2REG

|

136.1

|

|||

|

9 1/2 - 13 3/4

|

241.3 - 349.3

|

6 5/8REG

|

187.7

|

|||

|

14 - 14 3/8

|

355.6 - 365.1

|

6 5/8REG

|

187.7

|

|||

|

14 1/2 - 17 1/2

|

368.3 - 444.5

|

6 5/8REG OR 7 5/8REG

|

187.7 OR 215.9

|

|||

|

17 5/8 - 18 1/2

|

447.7 - 469.9

|

6 5/8REG OR 7 5/8REG

|

187.7 OR 215.9

|

|||

|

18 5/8 - 26

|

473.1 - 660.4

|

7 5/8REG OR 8 5/8REG

|

215.9 OR 243.3

|

|||

|

≥27

|

≥685.8

|

8 5/8REG

|

243.3

|

|||

Product features and uses

1. The floating bearing structure is adopted, and the floating element is made of new material with high strength, high elasticity, high temperature resistance and high wear resistance. The surface is treated by solid lubricant.

2, the use of high-precision rubber seal. The optimized sealing compression ensures that the two metal ring sealing surfaces are always in good contact.

3, steel ball locking cone, adapt to high speed.

4, the use of all-rubber oil storage sac that can limit the pressure difference and prevent drilling fluid from entering the lubrication system provides a good lubrication guarantee for the bearing system.

5, the use of 250°C high temperature, anti-wear new grease.

6. The tooth surface of the steel tooth bit is welded with a new wear-resistant material, which improves the life of the bit cutter while maintaining the high mechanical drilling rate of the steel tooth bit.

Cone bit is widely used in oil and gas drilling, water well, geothermal drilling, coal mine exploration, mining, bridge construction and so on.

Specification

Description of PDC drill bit

1.Suitable for soft, medium and hard formations.

2.Super strong material promotes gauge wear resistance to provide long bit life.

3.The cutter’s back rake has been unique design, reducing the bit torque and increasing aggressiveness.

4.Cuttings removal and bit cooling for bits are optimized by matching the volume of rock removed by the cutter on each bladewiththe proportional fluid flow.

2.Super strong material promotes gauge wear resistance to provide long bit life.

3.The cutter’s back rake has been unique design, reducing the bit torque and increasing aggressiveness.

4.Cuttings removal and bit cooling for bits are optimized by matching the volume of rock removed by the cutter on each bladewiththe proportional fluid flow.

Function

When the drill bits work, the edge is used to cut ordinary and symmetrical formation, while the ledge acts as cushioning toavoidhuge drilling footage, which helps to low the possibility of damage. Thanks to that, the drilling level of complicated formationis improved.

Application

Our PDC drill bits are widely used in various industries, such as coal mining, petroleum exploration, geological exploration, water conservancy and hydropower, railway and highway, tunnel construction, etc.

Steel drill bits are used for drilling blowholes, drainage holes, and grouting holes in coal mines and water conservancy projects; Blade drills are mainly used for drilling soft media formations, such as mudstone, limestone, shale, sandstone, and granite.

Hot Searches