- Product Details

- {{item.text}}

Quick Details

-

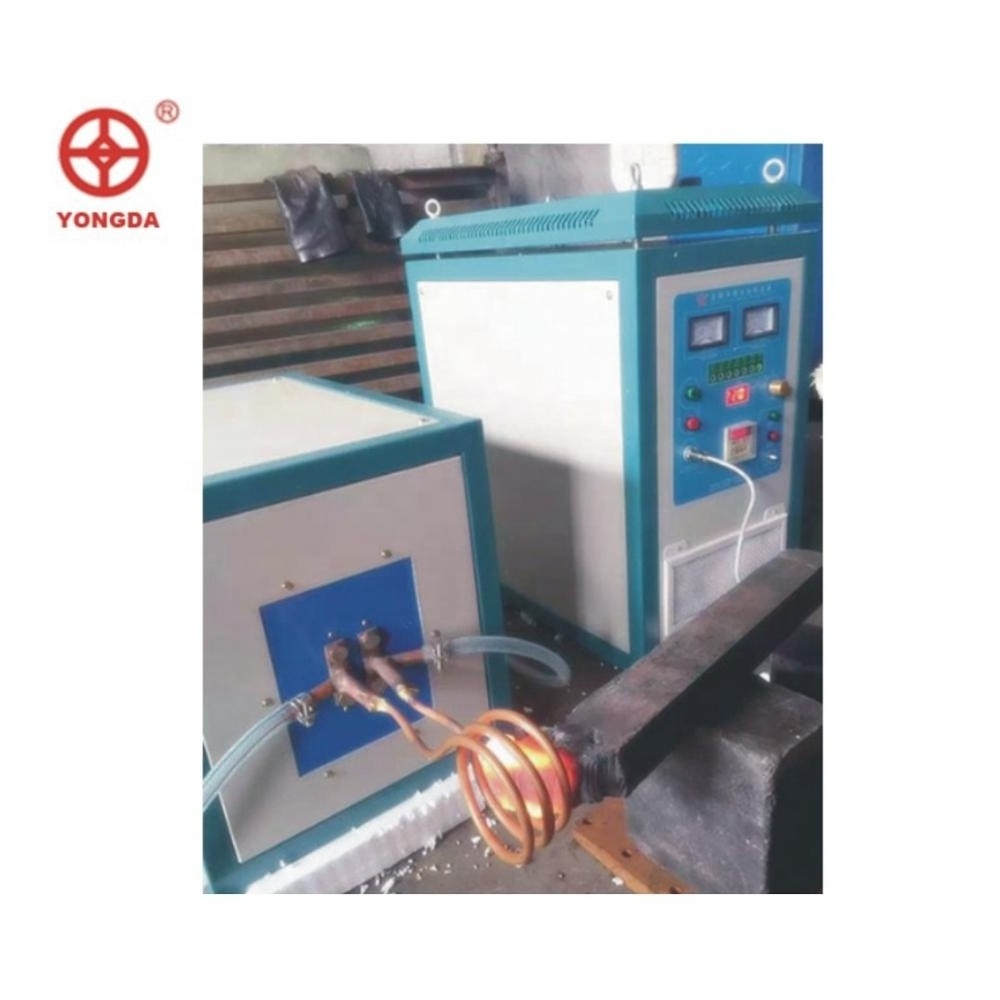

Brand Name:

-

Yongda

-

Weight (KG):

-

80

-

Voltage:

-

380V or customized

-

Current:

-

4-60A

-

Rated Capacity:

-

35kva

-

Rated Duty Cycle:

-

100%

-

Use:

-

brazing welding heating copper pipe

-

name:

-

copper tube heating welding machine

-

usage:

-

welding lathe tool,drill bits, hard alloy,copper tube

-

Power model:

-

10kw,20kw,35kw,65kw,120kw,160kw

-

accessories:

-

induction coils

-

protect function:

-

OC,OV,LP, etc. over ten alarm lamps

-

frequency:

-

auto tracking

-

technology:

-

IGBT module

-

market:

-

Asia, Africa, south america, middle east, europe

-

power:

-

10-35KW

-

Certification:

-

CE ISO

Quick Details

-

Marketing Type:

-

Hot Product

-

Core Components:

-

IGBT

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yongda

-

Weight (KG):

-

80

-

Voltage:

-

380V or customized

-

Current:

-

4-60A

-

Rated Capacity:

-

35kva

-

Rated Duty Cycle:

-

100%

-

Use:

-

brazing welding heating copper pipe

-

name:

-

copper tube heating welding machine

-

usage:

-

welding lathe tool,drill bits, hard alloy,copper tube

-

Power model:

-

10kw,20kw,35kw,65kw,120kw,160kw

-

accessories:

-

induction coils

-

protect function:

-

OC,OV,LP, etc. over ten alarm lamps

-

frequency:

-

auto tracking

-

technology:

-

IGBT module

-

market:

-

Asia, Africa, south america, middle east, europe

-

power:

-

10-35KW

-

Certification:

-

CE ISO

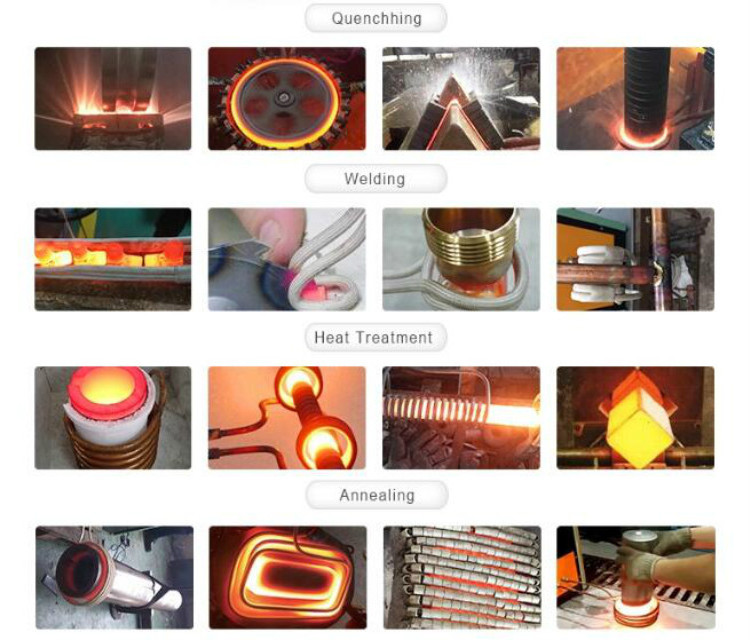

Applications of induction welding machine

|

Model

|

Voltage

|

Output power

|

Output current

|

Oscillation frequency

|

Size /weight

|

|

WGH-16

|

single phase 220V

|

10KW

|

35A

|

30-100KHZ

|

410*200*420mm/28kg

|

|

WZP-60

|

3PH,380V

|

35KW

|

60A

|

30-80KHZ

|

590*300*650mm /41kg ;500*360*455mm/37kg

|

Shenqiu Yongda High Frequency Equipment Co., Ltd. was founded in 1996, which belongs to high-tech enterprise in Henan Province,China. We are located in Shenqiu County, Zhoukou City. We professionally dedicated to Research & Development,production of high frequency induction heating machine, medium frequency induction heating equipment,supersonic frequency induction heating machine,induction forging machine, induction hardening machine, adhering to the spirit of innovation, mean while strengthening cooperation with domestic well-known universities and research institutions. We are the leader of domestic induction heating field, and got the ISO9001:2000 international quality management system certification in August, 2004, CE certifications in 2015. Up to now, we has 36 office in domestic ,products hot sale , and also exported to Europe,America,and Southeast Asia etc. other regions. We have international trade office in zhengzhou. East to international airport (CGO), besides, high way, high speed rail,transport is very convenient.