- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Voltage:

-

220v-10kv

-

Power:

-

25kw

-

Weight (KG):

-

12000

-

Product name:

-

Continuous biomass carbonization furnace

-

Capacity:

-

500 kg/h

-

Drum diameter(mm):

-

1300

-

Drum length(m):

-

12

-

Heating source:

-

Biomass, natural gas, diesel, coal

-

Application material:

-

Wood chips, coconut shell,rice husks, peanut shells, plant stalks

-

Material:

-

Carbon Steel, Refractory

-

Feature:

-

Continuous Machine

-

Color:

-

Customers Request

-

Diameter(mm):

-

1000-3600

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jiutian

-

Effective Volume:

-

4-12 m3

-

Dimension(L*W*H):

-

Customized

-

Voltage:

-

220v-10kv

-

Power:

-

25kw

-

Weight (KG):

-

12000

-

Product name:

-

Continuous biomass carbonization furnace

-

Capacity:

-

500 kg/h

-

Drum diameter(mm):

-

1300

-

Drum length(m):

-

12

-

Heating source:

-

Biomass, natural gas, diesel, coal

-

Application material:

-

Wood chips, coconut shell,rice husks, peanut shells, plant stalks

-

Material:

-

Carbon Steel, Refractory

-

Feature:

-

Continuous Machine

-

Color:

-

Customers Request

-

Diameter(mm):

-

1000-3600

Product Description

Rotary

Continuous Carbonization Equipment

Introduction

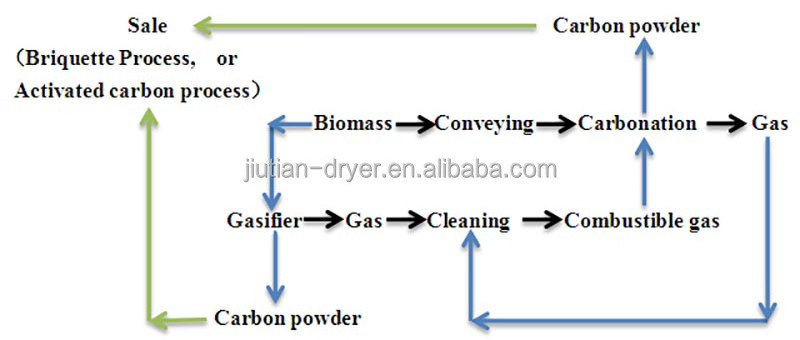

Environmentally-friendly drum continuous carbonation machine uses the carbonized flue gas purification into combustible gas generated in combustion itself. it can continuous product 24 hours. It has advantages of zero pollution, zero-emission, save labor, high capacity, energy-saving consumption, a high degree of automation, and advanced technology. Which is suitable for large-scale production, with a high carbonation rate, high carbon production rate, energy saving, environmental protection, high-efficiency advantages.

Working Principle

Application

This machine is suitable for carbonization of various forestry and agricultural powdery small-granular biomass. Such as: wood chips, wood blocks, bamboo chips, coconut shells, walnut shells, apricot shells, jujube shells, cherry shells, peanut shells, rice husks, cotton stalks, wheat stalks, dried tofu, etc.

Product Paramenters

|

Model

|

Capacity(kg/h)

|

Power(kw)

|

Drum diameter(mm)

|

Drum length(m)

|

Material

|

|||||

|

JTLT300

|

300

|

30-40

|

1000

|

12

|

304 stainless steel

|

|||||

|

JTLT500

|

500

|

40-50

|

1300

|

12

|

10

|

|||||

|

JTLT700

|

700

|

50-70

|

1600

|

12

|

10

|

|||||

|

JTLT1000

|

1000

|

70-80

|

1200

|

12

|

12

|

|||||

|

JTLT1500

|

1500

|

90-110

|

1400

|

12

|

12

|

|||||

|

JTLT2000

|

2000

|

110-130

|

1600

|

12

|

12

|

|||||

|

JTLT2500

|

2500

|

130-150

|

1900

|

12

|

12

|

|||||

|

Note: The price above is just for reference, please feel free to contact us if you want to know more about different models or production lines. We can offer free customized proposals.

|

|

|

|

|

|

|||||

Product Advantages

Product Features

1. Configure the new gasifier to generate gas in the early stage;

2. Equipped with flue gas purification, heat exchange and cooling systems to convert hot steam into water and flue gas into combustible gas for recycling;

3. Equipped with frequency conversion feeding machine, automatic feeding, feeding speed can be adjusted;

4. Equipped with drum carbonization main machine to meet the output requirements;

5. Configure a cooling discharge machine to cool the finished product and output the finished product;

6. Equipped with a control cabinet, the temperature and speed can be adjusted at will, the drum type continuous carbonization equipment adopts PLC automatic control cabinet, color display screen, and the production status is clear at a glance.

Successful Case

Company Introduction

Founded in 2003, Zhengzhou Jiutian is an enterprise with 200 employees committed to enhancing clients' productivity, profitability, and safety. Jiutian has developed more than 200 patented products for the drying machine.

Jiutian Machinery products include biomass drying and pelletizing production line, feed dregs drying equipment, coal drying upgrading equipment, poultry manure drying equipment, coconut fiber, coir drying machine, and related wood shaving machine, pellet machine, dehydration machine, carbonization furnace, etc.

At present, Jiutian not only has a huge customer resource system and considerable market share in the country but also in the UK, Russia, Greece, Italy, Israel, Morocco, Congo, Côte d'Ivoire, Madagascar, Australia, India, Vietnam, Laos, Indonesia, Malaysia, Sri Lanka. In Chile, the United States and other countries have established a case of dryers and successfully put them into production, to achieve the quality and technology of dryer products and international standards.

FAQ

Hot Searches