- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shengda Ceramic

-

Product name:

-

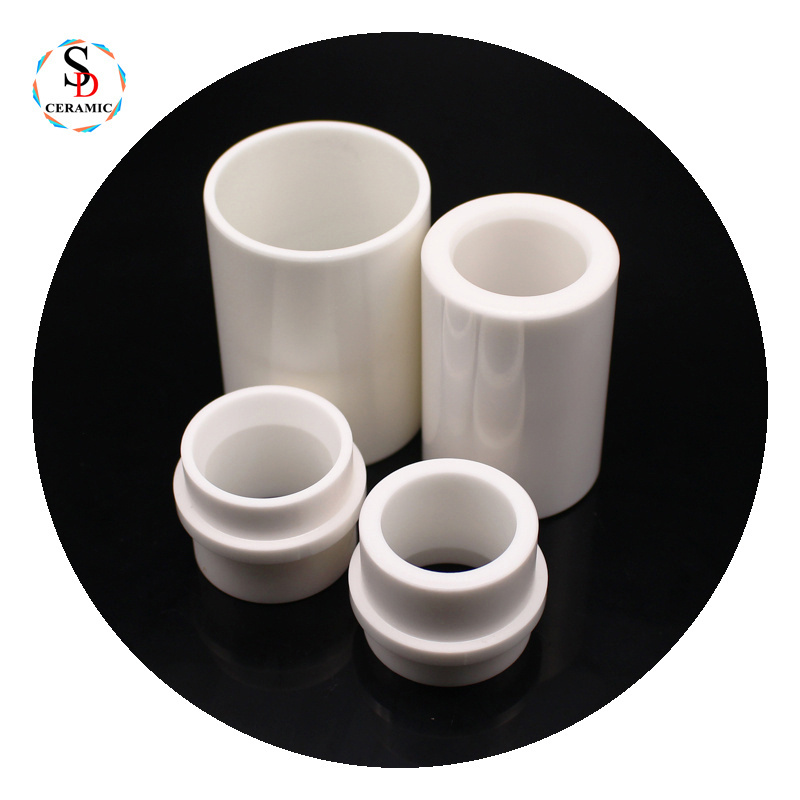

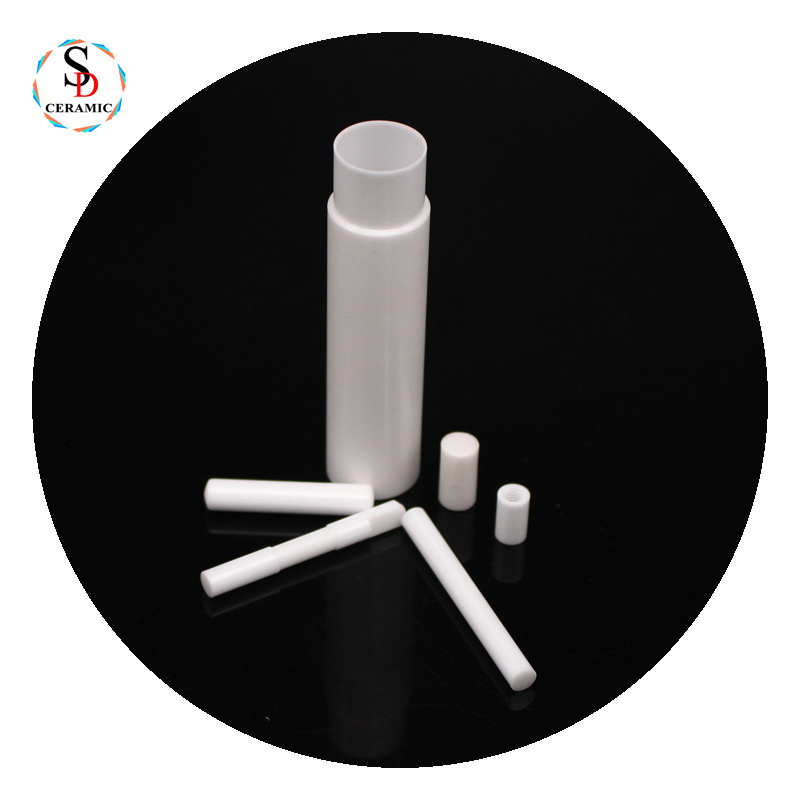

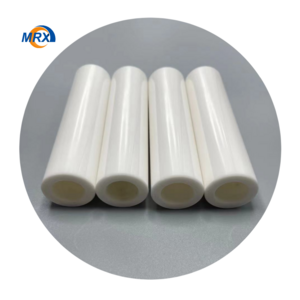

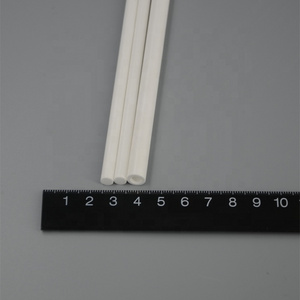

YSZ Zirconia Ceramic Tube/Mechanical Wear System Shaft Piston Plunger

-

Bulk Density:

-

6

-

Compressive strength:

-

25000

-

Sintering temperature:

-

1600℃

-

Customized:

-

According to Drawing

-

Hardness:

-

1300

-

Production Process:

-

Hot Injection/ Dry pressing

-

Thermal shock resistance:

-

360

-

Advantage:

-

Insulation ceramic

-

Fast Delivery Time:

-

15 days

Quick Details

-

Material:

-

Zirconia Ceramic

-

Place of Origin:

-

Jiangsu, China

-

Model Number:

-

SD

-

Brand Name:

-

Shengda Ceramic

-

Product name:

-

YSZ Zirconia Ceramic Tube/Mechanical Wear System Shaft Piston Plunger

-

Bulk Density:

-

6

-

Compressive strength:

-

25000

-

Sintering temperature:

-

1600℃

-

Customized:

-

According to Drawing

-

Hardness:

-

1300

-

Production Process:

-

Hot Injection/ Dry pressing

-

Thermal shock resistance:

-

360

-

Advantage:

-

Insulation ceramic

-

Fast Delivery Time:

-

15 days

Product Description

Zirconia

Ceramic

The production of zirconia ceramic requires the preparation of high purity, fine dispersion, ultrafine particles and narrow particle size distribution. Zirconia ultrafine powders are prepared by many methods, such as chlorination and thermal

decomposition, alkali metal oxidation, lime melting, plasma arc, precipitation, colloid, hydrolysis, spray pyrolysis, etc.

decomposition, alkali metal oxidation, lime melting, plasma arc, precipitation, colloid, hydrolysis, spray pyrolysis, etc.

Advantages

1. High hardness

2. Good wear resistance

3. High toughness

4. Low friction coefficient

5. Good corrosion resistance

2. Good wear resistance

3. High toughness

4. Low friction coefficient

5. Good corrosion resistance

Technical Parameters

|

Properties

|

Units

|

Steatite Ceramic

|

Cordierite Ceramic

|

Mullite

Ceramic

|

95%

Al2O3

|

99%

Al2O3

|

Zirconia

Ceramic

|

Silicon

Nitride

|

|

Colour

|

|

White

|

Yellow

|

White

|

White

|

Ivory

|

White

|

Grey

|

|

Density

|

g/cm3

|

2.7

|

1.9

|

2.6

|

3.5

|

3.85

|

6

|

3.2

|

|

Flexural Strength

|

Mpa

|

140

|

30

|

120

|

280

|

340

|

1150

|

600

|

|

Compressive Strength

|

MPa

|

900

|

350

|

500

|

2100

|

2200

|

2500

|

2500

|

|

Max Use Temperature

|

°C

|

1000

|

1200

|

1300

|

1400

|

1650

|

1500

|

1800

|

|

Thermal Condutivity

|

W(m.K)

|

2~3

|

1.3~1.8

|

2~6

|

16~28

|

19~30

|

2.5

|

20

|

|

Thermal Expansion Cofficient

|

10-6/°C

|

7 ~ 9

|

1.5~3.5

|

5~6

|

6.5~7.5

|

6~8

|

8~10

|

3~4

|

|

ThermalShock Resistance

|

△TC

|

100

|

300

|

150

|

140

|

150

|

250

|

600

|

|

Specific Heat

|

J/kg.K

|

850

|

800

|

900

|

950

|

950

|

500

|

500

|

|

Dielectric Strength

|

KV/mm

|

20

|

—

|

30

|

12

|

10

|

5

|

20

|

|

Dielectric Constant

|

Er

|

6

|

—

|

8

|

9

|

9

|

12

|

6

|

Production Process

Delivery&Packaging

Company Profie

Yixing Shengda Refractory Ceramic Co., Ltd, established in 1995, Yixing, China with an area of 4,000 square meters and fixed assets of over 1 million US dollars, is a professional manufacturer of Steatite Ceramic Parts, Alumina Ceramic Parts, Cordierite Ceramic Parts, Ceramic Band Heater Insulators, Ceramic Terminal Block, Thermostat Ceramic Parts, Zirconia Ceramics Parts, Ceramic Heater Plugs, etc.

Shengda Ceramic equipped with CAD/CAXA/Solidworks software to provide professional OEM & ODM service.

Looking forward to co-operating with the customers from all over the world!

Looking forward to co-operating with the customers from all over the world!

Contact Us

FAQ

Q1: Why choose shengda ceramic ?

A: We are the manufacturer of different kinds of industrial ceramics of 25 experiences and obtained the certificate of RoHS, SGS. We have 4000 square meters of work space and 1 million USD advanced facilities,providing lowest price.

Q2: Can you supply customize service?

A: Yes, we have a professional team which has rich experience in industrial ceramics, so We can supply OME & ODM service according to your drawings or requirement.

Q3: How is your goods quality?

A: We cooperated with several famous companies, like Mitsubishi; Media; Toshiba; Philips;etc. We have QC department to carry out the inspection before shipping.

Q4: What countries are your products exported to?

A: Our foreign trade business have started from 2013 year.We have exported our products to more than 10 countries such as United States, Spain, Italy, Croatia, United Arab Emirates, Jordan, Chile, India, Vietnam, etc.

Q5: How is your production capacity? How long is the delivery time?

A: 300,000 pieces per month. It usually takes 5-10 days to complete the item if the goods are in stock. It’s 15-20 days if the goods are not in stock, according to quantity.

Hot Searches