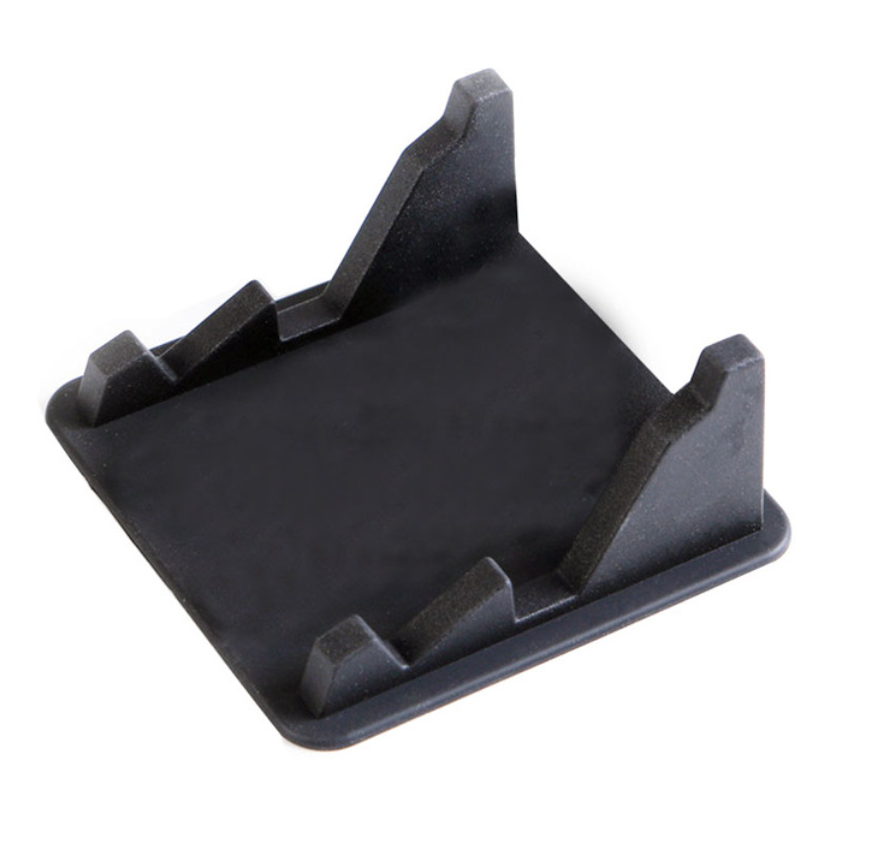

- Product Details

- {{item.text}}

Quick Details

-

Plastic cavity:

-

Single or Multi cavity

-

Mould material:

-

45#,50#,P20,H13, 718 2738, NAK80,etc

-

Mold runner:

-

Cold or Runner

-

Material:

-

POM,PC,ABS,POM,PP,PE or custom

-

Size:

-

Customized Size

-

Mold base:

-

LKM, HASCO, DME or your requirement

-

Color:

-

Any Color

-

Products:

-

motor spare parts auto mold

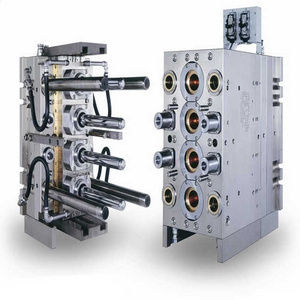

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Keyword:

-

plastic injection molding services

-

Gate type:

-

Side gate,Sub gate,Pin point gate,Edge gate,etc

-

Plastic cavity:

-

Single or Multi cavity

-

Mould material:

-

45#,50#,P20,H13, 718 2738, NAK80,etc

-

Mold runner:

-

Cold or Runner

-

Material:

-

POM,PC,ABS,POM,PP,PE or custom

-

Size:

-

Customized Size

-

Mold base:

-

LKM, HASCO, DME or your requirement

-

Color:

-

Any Color

-

Products:

-

motor spare parts auto mold

Custom car injection molding steering wheel airbag plastic cover mold

|

Company |

Shenzhen A&R Technology Co,Ltd |

| Design Software | UG,Pro E Solidwork,AutoCAD,Moldflow.... |

| Core&Cavity Material | P20,H718,S136,SKD61,2738,DC53,H13.... |

| Mold base | HASCO ,DME ,LKM,JLS standard |

| Mould Cavity | Singe or multi cavity |

| Mold strandard parts | DME, HASCO, etc. |

| Runner | Hot runner, Cold runner |

| Hot Runner Brand | Yudo/ Mastip/ HASCO/ DME/ MOLD-MASTER…etc |

| Mold cold runner | Side gate,Sub gate,Pin point Gate... |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 20~60 HRC |

| plastic Injection Machine | 10sets,110T,140T,160T, 200T,260T,320T |

| Plastic Material | PP,Pa6,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| MOQ | 1set for mold ,plastic products as per your request |

| Mold Life | 300000-500000 shots as per customers' requirement |

| Inspection | As customers’ requirements |

| Delivery | Air cargo, Sea shipping |

| Lead time | 25-35days for mold,plastic products according to quantity |

| Keyword | Custom car injection molding steering wheel airbag plastic cover mold |

Product details:

Product Show:

Our Hot Moulds:

Our Certifications:

About us:

Our Factory:

Why choose us?

FAQ:

Q. How can I get the accurate price?

A. There are some basic specs we need to know for price calculate, that are:

3D drawings in STP, IGS, X-T format are avaialble, Please suggest us your

quantity too.

Q: Are you trading company or manufacturer?

A: We are factory.

Q I have an idea for a new product, but don't know if it can be

manufactured. Can you help?

A Yes! We are always happy to work with potential customers to evaluate the

technical feasibility of your idea or design and we can advise on materials

tooling and likely set-up costs.

Q What type of mould tool do I need?

A Mould tools can be either single impression (one part at a time)or multi-

impression(2, 4, 8 or 16 parts at a time). Single impression tools are

generally used for small quantities, up to 10,000 parts per year whereas

multi-impression tools are for larger quantities. We can look at your projected

annual requirements and recommend which would be best for you.

Q If I've decided to go ahead with my project. How long will it take to get

the trial shot sample?

A. It will take 3-8 weeks to have the tooling manufactured which depend on

the part's complexity and the number of impressions(single or multi). After

the tooling is completed, you can expect delivery of trial shot samples within

2-3 days.

You Just need:

Packaging Shipping:

1. For mold: After assemble and clear mold, we have anti-rust paint or grease on

mold, the cover it with thin film and place it into a stable wooden box.

2. For plastic product: will wrap each part up with semi-transparent thin foam and/or

put it into plastic bag, then place then into cartons to prevent scratches

Welcome To Contact Us For Good Mold Product!!