- Product Details

- {{item.text}}

Quick Details

-

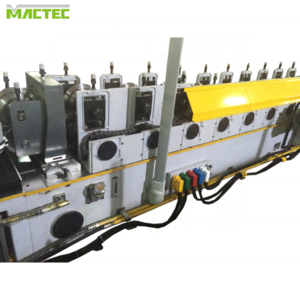

Power:

-

7500

-

Weight:

-

3000 kg

-

Product name:

-

Light Keel Roll Forming Machine

-

Application:

-

Building Construction

-

Raw material:

-

Steel Coil

-

Material Thickness:

-

1.5-3mm

-

Control system:

-

PLC(detla) System

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Roller station:

-

18 Stations

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Cutting system:

-

Hydraulic Tracking Cutting

Quick Details

-

Production Capacity:

-

10-45 meter/minute

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jiyun

-

Power:

-

7500

-

Weight:

-

3000 kg

-

Product name:

-

Light Keel Roll Forming Machine

-

Application:

-

Building Construction

-

Raw material:

-

Steel Coil

-

Material Thickness:

-

1.5-3mm

-

Control system:

-

PLC(detla) System

-

Roller material:

-

45#steel Chrome Plated

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Roller station:

-

18 Stations

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Cutting system:

-

Hydraulic Tracking Cutting

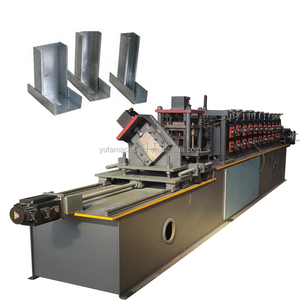

Products Description

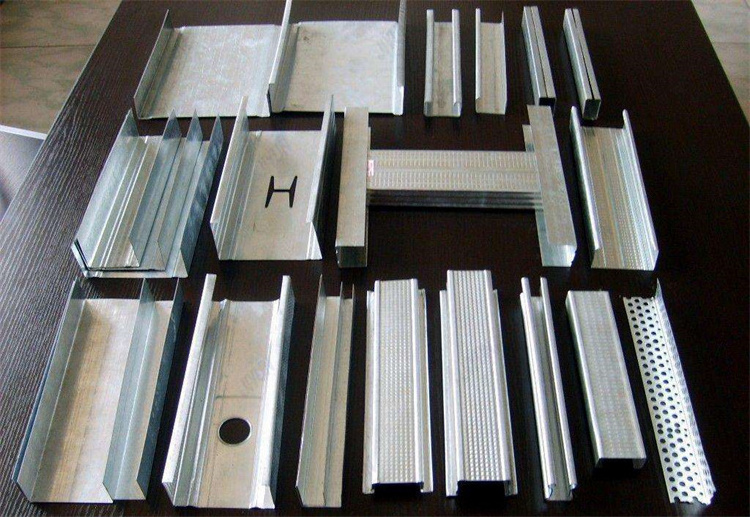

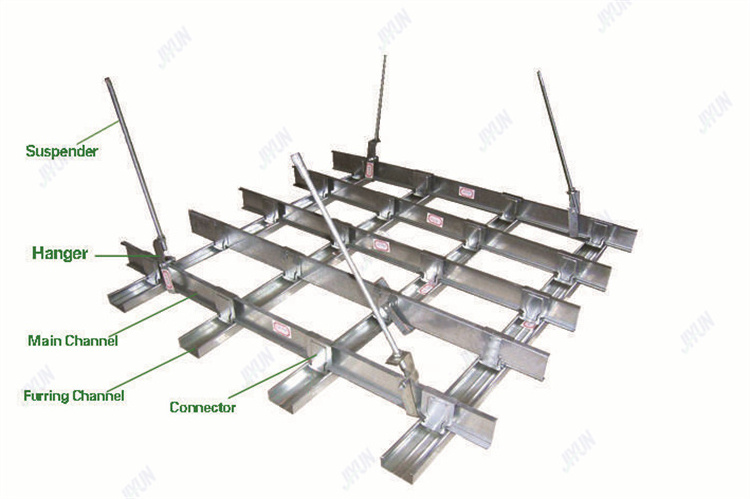

Light steel keel machine is a series of products designed to meet the needs of the cold roll forming machine market. The keel machine is divided into wall keel, ceiling keel, ceiling cassette keel, etc., with strip steel as raw material, through continuous cold rolling forming. The production of complex cross-sectional profiles (products are: light steel keel, paint keel, cassette keel, various building profiles, steel structure, steel lining door frame profiles, high-speed guardrails, etc.) and can design and manufacture different specifications of cold bending and paint unit equipment according to customer requirements.

Product Parameter

|

Item

|

Name

|

Quantity

|

|

1

|

Uncoiling Device

|

1 set

|

|

2

|

Forming Main Machine

|

1 set

|

|

3

|

Hydraulic Cutting System

|

1 set

|

|

4

|

Material Receiving Table

|

1 set

|

|

5

|

PLC Control System

|

1 set

|

|

6

|

Supporting Accessories

|

1 set

|

|

Item

|

Parts

|

Specification & Description

|

|

1.Raw Material

|

Type

|

GI / GL /PPGI / PPGL /Customization steel coil

|

|

|

Thickness(mm)

|

0.5-2

|

|

2.Un-coiler Device

|

Type

|

Inner contraction range

|

|

|

Max Loading(Tons)

|

300-800 KG(optional)

|

|

|

Way of working

|

Manual / Electric / Hydraulic tensioning crank.

|

|

|

Panel Width(mm)

|

200-650mm(customizable)

|

|

|

Coil Inner diameter

|

φ480-500mm

|

|

|

Inner adjust range

|

φ450-550mm

|

|

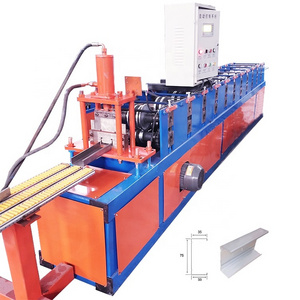

3.Forming Main Machine

|

Main frame

|

Material:300H/350H steel

Processing:Welding frame

|

|

|

Middle plate

|

Material : 45#steel

Thickness: 14mm Processing :laser cutting |

|

|

Shaft

|

Material : 45# steel with chrome 0.05mm

Diameter : 70mm Processing : Precision machining, heat treatment, precision grinding |

|

|

Rollers

|

Material: 45# steel Chrome Plated

Processing : Quenching, precision turning, polishing treatment |

|

|

Roller Station

|

10-16 stations or Customization

|

|

|

Transmission

|

Specifications:1 inch chain wheel with gear transmission

Processing :Quenching heat treatment Gear oil:18 # hyperbolic gear oil |

|

|

Main Motor

|

Power:5.5KW

Brand:Lichao(optional) Reducer: Cycloidal reducer Protection level:IP55 Explosion-proof level:ExdIICT4 |

|

4.Cutting System

|

Type

|

Automatic Hydraulic Cutting

|

|

|

Blade material

|

Cr12MOV heat treatment process

|

|

|

Pump

|

hydraulic pressure:10-12mpa

Hydraulic oil: 46# |

|

|

Pump motor for cutter

|

Power: 4KW

|

|

5.Receiving rack

|

Type

|

manual / Electric receiving rack

|

|

6.PLC Control System

|

PLC Control System

|

Plc brand:Delta (optional)

Text control box:Vertical LCD touch screen control box/Swing arm LCD touch screen control box Language: English / Chinese / Customized |

|

|

Inverter

|

Rated power:7.5KW

|

Details Images

Hot Searches