- Product Details

- {{item.text}}

Quick Details

-

Spindle Bore(mm):

-

32

-

Width of bed (mm):

-

0 mm

-

Spindle Motor Power(kW):

-

3.7/7.5

-

Travel (X Axis)(mm):

-

200 mm

-

Travel (Z Axis)(mm):

-

190 mm

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

2470*1600*1700

-

Brand Name:

-

JIANKE

-

Model Number:

-

MR326

-

Voltage:

-

380V

-

Weight (KG):

-

3980

-

Operation System:

-

Taiwan SYNTEC

-

Spinlde and Driver:

-

Oil cooling electric spindle

-

Bearing:

-

Japan NSK

-

Japan NSK:

-

Japan THK

-

Screw:

-

Japan THK

-

Servo motor:

-

Japan Yaskawa

-

Motor Driver:

-

Japan Yaskawa

-

Electrical components:

-

Germany Schneide

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

2000

-

Max. Spindle Speed (r.p.m):

-

8000 r.p.m

-

Spindle Bore(mm):

-

32

-

Width of bed (mm):

-

0 mm

-

Spindle Motor Power(kW):

-

3.7/7.5

-

Travel (X Axis)(mm):

-

200 mm

-

Travel (Z Axis)(mm):

-

190 mm

-

Place of Origin:

-

Jiangsu, China

-

Dimension(L*W*H):

-

2470*1600*1700

-

Brand Name:

-

JIANKE

-

Model Number:

-

MR326

-

Voltage:

-

380V

-

Weight (KG):

-

3980

-

Operation System:

-

Taiwan SYNTEC

-

Spinlde and Driver:

-

Oil cooling electric spindle

-

Bearing:

-

Japan NSK

-

Japan NSK:

-

Japan THK

-

Screw:

-

Japan THK

-

Servo motor:

-

Japan Yaskawa

-

Motor Driver:

-

Japan Yaskawa

-

Electrical components:

-

Germany Schneide

Products Description

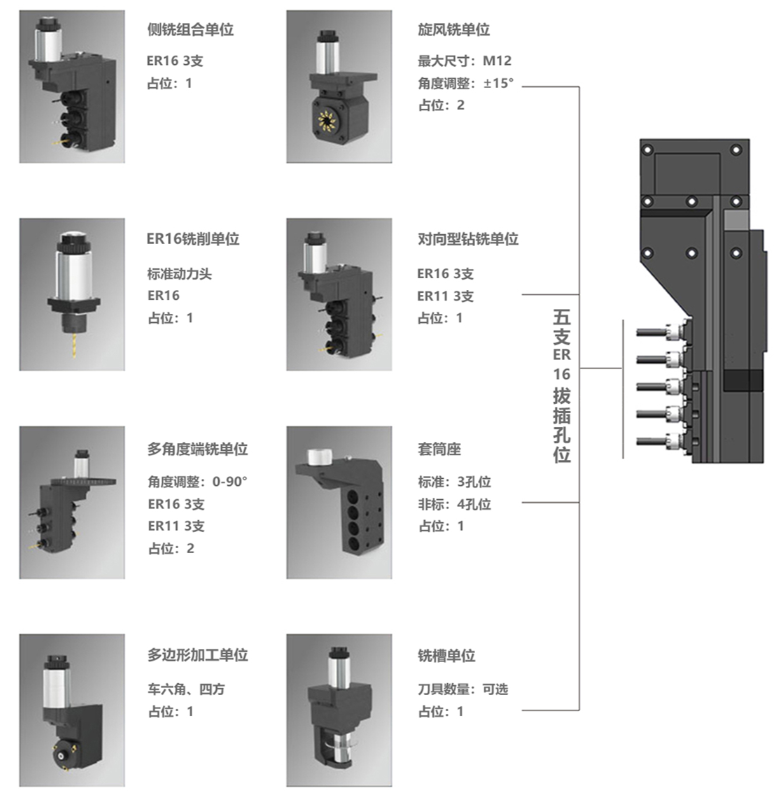

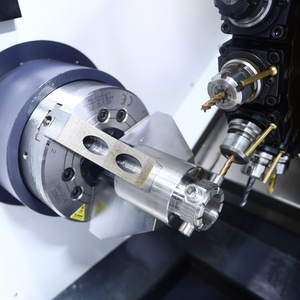

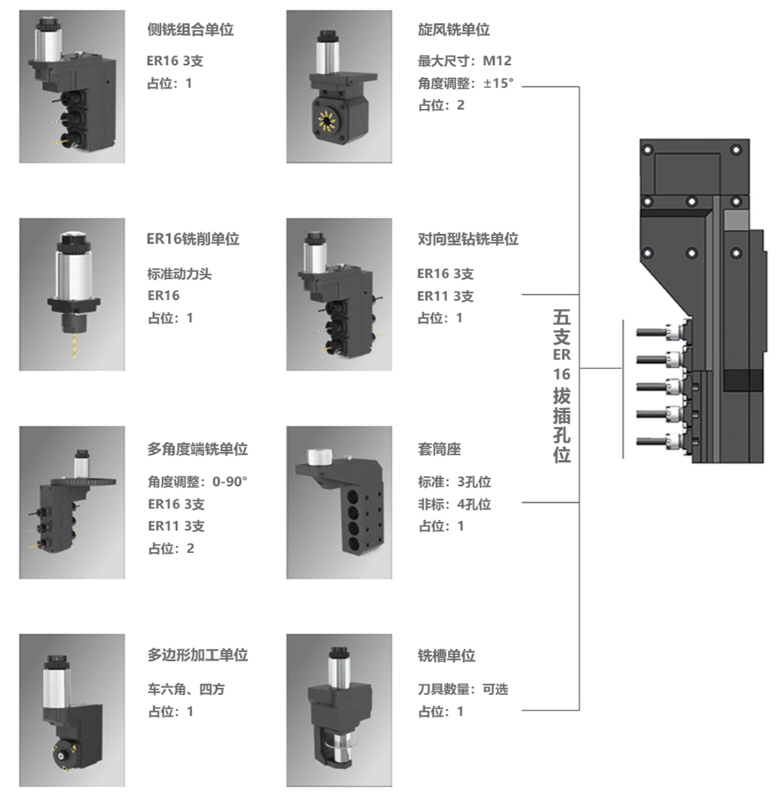

Lathe Appearance/Tool Holder Structure

Swiss type CNC lathe double spindle 6 axis model MR32-6 Ⅱ

●excellent performance

●ability powerful

●Operate flexbile

●ability powerful

●Operate flexbile

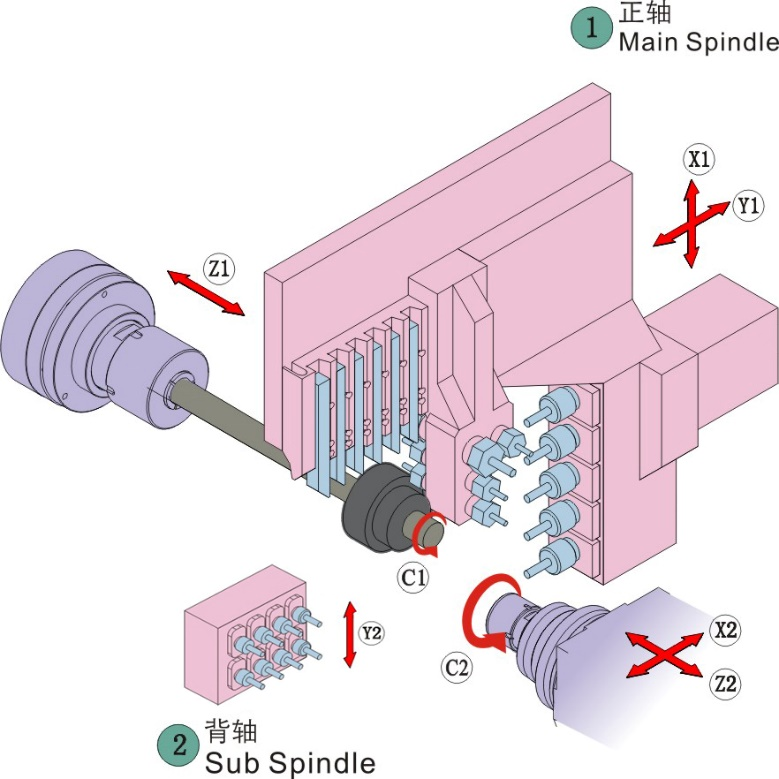

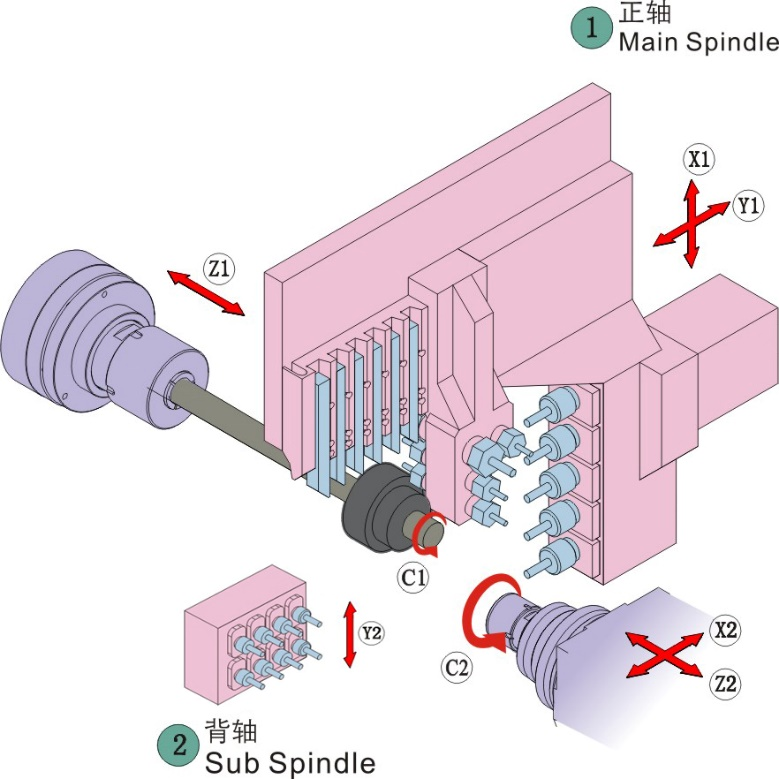

Main spindle & Sub spindle

●Main and sub spindle C axis stantard configration,complete functions

●Excellent performance multi types of tools coordinate

reasonably,multi tool frame rasonably option

●rotary guide sleeve、no guide bush freely option, save material high benefit.

reasonably,multi tool frame rasonably option

●rotary guide sleeve、no guide bush freely option, save material high benefit.

Details Images

1.Characteristics

1、Rotary Guide bush/Without guide bush changeable modes Support Rotary Guide bush/Without guide bush changeable modes. When using rotary guide bush mode, it is suitable for processing shaft workpieces, with a single feeding length of 195~200mm and support for multiple feeding. The tail material length is 180mm; When using without guide bush mode, it is suitable for processing short workpieces with a length to diameter ratio of less than 1:2.5, which can minimize the length of the tail material. The length of the tail is 50mm

2、Internal oil cooled electric spindle Adopting Japan oil cooled electric spindle technology, independently designed and developed, we have overcome the core problems of the spindle of the Swiss CNC lathe machine. Compared with other

electric spindles of the same power, we have stronger rigidity and torque force, and more stable processing accuracy. Using NSK bearings to extend spindle life and radial stability.

electric spindles of the same power, we have stronger rigidity and torque force, and more stable processing accuracy. Using NSK bearings to extend spindle life and radial stability.

3、Scrap collection tank/large capacity cutting oil tank The waste collection box adopts a separation platform for chip collection, allowing the cooling oil to undergo preliminary buffering and cooling on the chip collection platform for preliminary oil chip separation; Then enter the cutting oil tank with a volume of 250L from the oil drain. The cutting oil tank is equipped with multi-channel filter screens and oil return baffles to extend the return path and separate /filter oil chips as far as possible; Make the oil temperature reach full Free cooling and reduce the debris entering the oil pump, so as to extend the service life of the oil pump.

4、Workpiece eject method: short parts ejected to the front of the conveyor belt/long parts ejected from the rear of sub spindle Jianke's full series of dual spindle Swiss CNC Lathe come standard with a collection method of front discharge products. When the length of the workpiece is less than 90mm, the front material receiving box can be used for collection and the product can be sent out through a built-in conveyor belt. When the product length is more than 90mm, the rear discharge method can be selected, and the product is ejected through the center of the sub spindle through a slot on the side sheet metal of the equipment.

5、Highly modular expansion function The JIANKE MA series lathes comes standard with 2 ER11+2 ER16. The 2 ER16 side rotary power tools supporting modular expansion functions that can be added with additional functions and tool positions according to demand. (The plug-in modules are all for options and if needed for such modules, please list them in the contract/quotation.)

2.Standard Accessories

|

1

|

Protective cover

|

1

|

|

|

2

|

Signage

|

1

|

Various warning signs, machine nameplates

|

|

3

|

Main spindle

|

2

|

Oil cooling electric spindle

|

|

4

|

Turning tool row seat

|

1

|

Upside tool seat

|

|

5

|

Side power tool holder

|

1

|

|

|

6

|

Main spindle end face drilling seat

|

1

|

|

|

7

|

Sub spindle end face drilling seat

|

1

|

|

|

8

|

Live rotary guide bush

|

1

|

|

|

9

|

Pneumatic system

|

1

|

Taiwan AIRTAG

|

|

10

|

cooling system

|

1

|

YUNHAI pump

|

|

11

|

Lubrication system

|

1

|

Japan HERG

|

|

12

|

Electrical System

|

1

|

Schneider

|

|

13

|

Material receive device

|

1

|

Material receive device / Long material aid device

|

|

14

|

Lathe lighting

|

1

|

DC24V

|

|

15

|

Three-color warning light

|

1

|

|

|

16

|

Special tool box

|

1

|

Special tools included

|

3.Options equipments(if needed , please list them in the contract/quotation)

|

NO

|

Name

|

Functions

|

Note

|

|||

|

1

|

Bar feeder

|

Realize automatic feeding/refueling function for long bar materials;

Assisting the Swiss CNC lathe to achieve automated production; |

Recommended essential

|

|||

|

2

|

High pressure pump

|

Assist in targeting materials that are prone to chip breakage, chip removal, and erosion, reducing the probability of tool chip

entanglement; Extend tool life; Improve the accuracy/smoothness of some machining steps; |

Select according to demand

|

|||

|

3

|

Oil mist collector

|

Absorb the atomized oil mist inside the equipment, reduce the overflow of oil mist from the equipment, and maintain the workshop

environment。 The models are divided into electrostatic type and filter type。 |

Select according to demand

If equipped with a high pressure pump Recommended mandatory oil mist collector |

|||

|

4

|

Chip conveyor

|

Chain type conveyor remove chips fro lathe collector, standard equipped with a chip trolley. Reduce the frequency and workload of

manual chip removal. |

Select according to demand

|

|||

|

5

|

Plug type modules

|

End face rotary tools/Angle rotary tools/Thread whirling/Hobbing base/Saw blade base/Boring tool base…

|

Due to various modules/functions, Please confirm with JIANKE according to actual machining requirements.

|

|||

|

6

|

Long parts discharge from backwards

|

If the parts are longer that the collector opening, need change to eject it from backwards of sub spindle

|

Select according to demand

|

|||

|

…

|

…

|

……

|

…

|

|||

|

Due to the different options/configurations of the Swiss CNC lathe, the above are regular configurations. If you have special needs, please communicate and confirm with JIANKE.

|

|

|

|

|||

4.Main accessory brand

|

Name

|

Origin and Brand

|

|

Operation System

|

SYNTEC(Made in TAIWAN)

|

|

Spinlde and Driver

|

Oil cooling electric spindle/Mitsubishi driver

|

|

Bearing

|

Japan NSK

|

|

Guide rail

|

Japan THK/Taiwan Hiwin/Taiwan PMI

|

|

Guide screw

|

Japan THK/Taiwan Hiwin/Taiwan PMI

|

|

Servo Motor

|

SYNTEC(Made in TAIWAN)

|

|

Motor driver

|

SYNTEC(Made in TAIWAN)

|

|

Electrical components

|

France Schneider

|

|

Lubricant system

|

Japan Herg

|

|

Relay

|

Japan Omron

|

|

Stroke switch

|

Japan Omron

|

|

Magnetic valve

|

Taiwan Airtag

|

5.Swiss CNC lathe requirements for raw materials in the processing of long bar materials.

1、Recommended use of polished/precision drawn materials: As the standard bar feeder supports a maximum length of 3M for bars, it is recommended that the length of a single bar material should be ≤ 3M;

2、Diameter tolerance within ± 0.02mm;roundness within 0.005-0.01mm;straightness within 0.35mm/m

3、All the bar materials need to be chamfered at both ends;

4、Some large-diameter materials and irregular(suquare/hexagonal) materials require to turning the tail of them to match the bar feeder collet and easy to be sent through the spindle hole;

5、When the material hardness is higher than HRC28 degrees, a prior declaration is required。

6. Quality assurance and technical support

The warranty period for the supplier's equipment is one year from the date of final acceptance by the Buyer before shipment. Under normal use, there is a free service warranty for damage. If the equipment is damaged due to improper use by the buyer, the supplier will only charge material fees within one year, and material and labor fees will be charged after one year. The supplier shall provide paid services /spare parts to the buyer for a long time. Make the following commitments to technical support,pre-sales, in sales, and after-sales service and quality

Product Paramenters

|

Double spindle Swiss CNC lathe MR32-6 II

|

|

|

|

|

||||

|

System

|

Taiwan SYNTEC

|

Syntec 210TB-A

|

|

|

||||

|

|

Control channel

|

Double channel

|

|

|

||||

|

|

Minimum setting unit

|

0.001mm

|

|

|

||||

|

Machining

|

Max processing diameter

|

32 mm

|

|

|

||||

|

|

Max processing length at one time

|

With guide bush

|

260mm

|

|

||||

|

|

|

Without guide bush

|

1:2.5D(Dia:Lenth)

|

|

||||

|

|

Main spindle max drilling Dia

|

Main spindle axial

|

ER20

|

Φ13mm

|

||||

|

|

|

|

ER16

|

Φ10mm

|

||||

|

|

|

|

ER11

|

Φ7mm

|

||||

|

|

Main spindle max tapping Dia

|

Main spindle axial

|

ER20

|

M12

|

||||

|

|

|

|

ER16

|

M8

|

||||

|

|

|

|

ER11

|

M6

|

||||

|

|

Power head max drilling Dia

|

Radial

|

Φ10mm

|

|

||||

|

|

Power head max tapping Dia

|

Radial

|

M8

|

|

||||

|

|

Sub spindle max drilling Dia

|

Sub spindle axial

|

Φ10mm

|

|

||||

|

|

Sub spindle max tapping Dia

|

Sub spindle axial

|

M8

|

|

||||

|

Tool

|

Tool seat arrangement

|

Upside tool seat

|

|

|

||||

|

|

Main spindle turning tool

|

6 pieces

|

6 pieces 16X16mm

|

|

||||

|

|

Main spindle side roatry power head

|

5 pieces

|

5 pieces ER16

|

|

||||

|

|

Main spindle end face fixed tool seat

|

4 pieces

|

3 pieces ER11/ER16+1 piece ER20

|

|

||||

|

|

Sub spindle end face tool seat(fixed/rotary changeable)

|

8 pieces

|

ER16

|

|

||||

|

Main

Spindle |

Main/sub spindle type

|

Built-in oil-cooled electric spindle

|

|

|

||||

|

|

Main/sub spindle speed

|

8000rpm/min

|

|

|

||||

|

|

Main/sub spindle index

|

0.001°

|

|

|

||||

|

|

Main/sub spindle hole Dia

|

34mm

|

|

|

||||

|

|

Main/sub spindle center height

|

1060mm

|

|

|

||||

|

Motor

power |

Main Spindle power (rated/maximum)

|

3.5kw/6.0kw

|

|

|

||||

|

|

Sub Spindle power (rated/maximum)

|

3.5kw/6.0kw

|

|

|

||||

|

|

Side rotary head motor power

|

1.7kw

|

|

|

||||

|

|

Side rotary head speed

|

5000rpm/min

|

|

|

||||

|

|

No. of moving axis

|

5 axis

|

X1、Y1、Z1、X2、Z2

|

|

||||

|

|

Rapid feeding speed

|

24m/min

|

|

|

||||

|

|

|

|

|

|

||||

|

|

Moving axis motor power

|

0.75kw

|

|

|

||||

|

Other

|

Parts receive device

|

Short bar

|

Parts conveyor collect parts

|

|

||||

|

|

|

Long bar

|

Sub spindle backside collect parts

|

|

||||

|

|

Power capacity

|

20kw

|

|

|

||||

|

|

Air pressure

|

Above 0.4MPa

|

|

|

||||

|

|

Cutting oil tank capacity

|

286L

|

|

|

||||

|

|

Machine size(L*W*H)

|

2.47m×1.6m×2.0m

|

|

|

||||

|

|

Lathe Weight

|

3880KG

|

|

|

||||

Certifications

Product packaging

Hot Searches