Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JWELL

-

Weight:

-

6000 KG

-

Name:

-

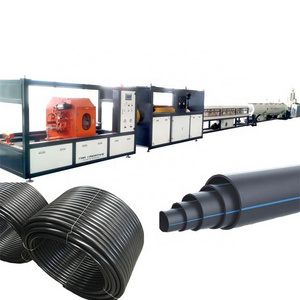

Corrugated Pipe Machine

-

Raw material:

-

PP PE PVC

-

After-sales Service Provided:

-

Engineers

-

Keywords:

-

HDPE Pipe Production Line

-

After Warranty Service:

-

Service

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Certification:

-

CE ISO

-

Cooling way:

-

Recycling Water Cooling

-

Gear box:

-

Flender

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

34:1

-

Screw Speed (rpm):

-

70 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JWELL

-

Weight:

-

6000 KG

-

Name:

-

Corrugated Pipe Machine

-

Raw material:

-

PP PE PVC

-

After-sales Service Provided:

-

Engineers

-

Keywords:

-

HDPE Pipe Production Line

-

After Warranty Service:

-

Service

-

Inverter:

-

ABB Brand

-

Motor:

-

SIEMENS Brand

-

Certification:

-

CE ISO

-

Cooling way:

-

Recycling Water Cooling

-

Gear box:

-

Flender

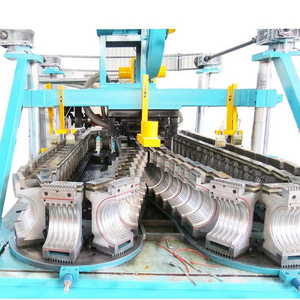

Jwell's newly developed horizontal double-wall corrugated production line is a second-generation horizontal pressure water cooling production line,which is independently developed on the basis of domestic and international advanced technologies.It has more than ten invention patents.

* There are a variety of types of extrudersto choose,which can achieve the production of various HDPE,PP pipe,alsocan meet the production demand of single-wall corrugated pipe.

* Sizing sleeve is madeof aluminum alloy,andthe surface is wear-resistant.The tube waveform can be calculated by special software program,and the ring stiffness can be obtained at the same weight.

* The sliding base of forming machine is geared and equipped with large size needle roller bearing,which improves the bearing capacity of the sliding base.More stable operation,longer life.

* Production line is fixed center height,and there is no need to adjust again when changing model;

* Common production line modules with different specifications.Quick unloading module design makes module loading and unloading convenient and fast.The unique internal module cooling design enables the cooling water to flow rapidly internal module realizes the rapid cooling and shaping of pipes.The main drive is driven by a two-speed motor,which can realize stable and accurate operation.

* Using advanced PLC and color LCD control system,which can be adjusted by single machine,linkage of all lines, simple operation,stable and reliable production,high degree of automation,automatic fault alarm.

* In addition to single screw extruder,tapered twin screw extruder and parallel twin screw extruder can be used in this production line.All three kinds of extruders are produced by JWELL ,with precise electronic control,good plasticizing and stable operation,which can meet the needs of different customers.

* There are a variety of types of extrudersto choose,which can achieve the production of various HDPE,PP pipe,alsocan meet the production demand of single-wall corrugated pipe.

* Sizing sleeve is madeof aluminum alloy,andthe surface is wear-resistant.The tube waveform can be calculated by special software program,and the ring stiffness can be obtained at the same weight.

* The sliding base of forming machine is geared and equipped with large size needle roller bearing,which improves the bearing capacity of the sliding base.More stable operation,longer life.

* Production line is fixed center height,and there is no need to adjust again when changing model;

* Common production line modules with different specifications.Quick unloading module design makes module loading and unloading convenient and fast.The unique internal module cooling design enables the cooling water to flow rapidly internal module realizes the rapid cooling and shaping of pipes.The main drive is driven by a two-speed motor,which can realize stable and accurate operation.

* Using advanced PLC and color LCD control system,which can be adjusted by single machine,linkage of all lines, simple operation,stable and reliable production,high degree of automation,automatic fault alarm.

* In addition to single screw extruder,tapered twin screw extruder and parallel twin screw extruder can be used in this production line.All three kinds of extruders are produced by JWELL ,with precise electronic control,good plasticizing and stable operation,which can meet the needs of different customers.

|

Type

|

Pipe size

|

Speed

|

Total power

|

Line lenght*width

|

|

JWBW-150

|

ID40-150

|

Max15

|

270

|

28×4.5

|

|

JWBW-300

|

ID100-300

|

Max5.5

|

340

|

30×6

|

|

JWBW-600

|

ID100-600

|

Max4.2

|

490

|

34×6

|

|

JWBW-800

|

ID200-800

|

Max7.5

|

615

|

38×8

|

|

JWBW-1000

|

ID300-1000

|

Max3.8

|

795

|

30×8.5

|

|

JWBW-1200

|

ID400-1200

|

Max2

|

890

|

30×9

|

|

JWBW-1500

|

ID600-1500

|

Max1.2

|

1110

|

42×9.5

|

Hot Searches