- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

26500mm X 2300mm X 3200mm

-

Weight:

-

25000KGS

-

Name:

-

BOPP Adhesive Tape Coating Machine

-

Heating type:

-

Electric/Thermo oil / Steam Gas (based on users)

-

Humidification System:

-

Optional

-

Touch screen:

-

Siemens

-

Speed:

-

0-200m/min

-

Usage:

-

Tape making

-

Coating thickness:

-

0.01-0.025 mm

-

Base Material:

-

BOPP Jumbo Roll

-

Coating method:

-

Comma Blade Coating

-

Color:

-

Customer's Requested

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

-

Certification:

-

CE

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

DABA

-

Dimension(L*W*H):

-

26500mm X 2300mm X 3200mm

-

Weight:

-

25000KGS

-

Name:

-

BOPP Adhesive Tape Coating Machine

-

Heating type:

-

Electric/Thermo oil / Steam Gas (based on users)

-

Humidification System:

-

Optional

-

Touch screen:

-

Siemens

-

Speed:

-

0-200m/min

-

Usage:

-

Tape making

-

Coating thickness:

-

0.01-0.025 mm

-

Base Material:

-

BOPP Jumbo Roll

-

Coating method:

-

Comma Blade Coating

-

Color:

-

Customer's Requested

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

-

Certification:

-

CE

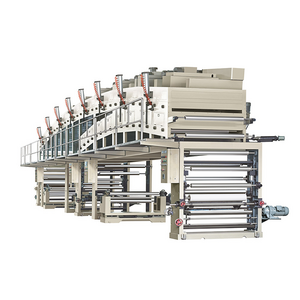

High Speed Self Adhesive Wallpaper Paper Film PET PVC BOPP Tape Coating Making Machine

Product Description

Applications

DBTB series

Self Adhesive Wallpaper Paper Film PET PVC BOPP Tape Coating Making Machine

is widely used for making BOPP Tape, Bopp Transfer tape ,Bopp box sealing tape ,Adhesive tape ,Masking tape, Electrical insulation tape, Reflective tape, Stationary tape, Kraft paper tape, and so on.

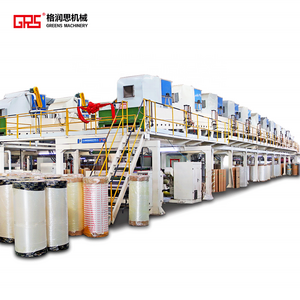

Suitable Material

It is mainly suitable for reel -type substrate coating production.The material such as Paper, Opp, Alumium, CPP, PET, Bopp, Fabric, Etc.

Characteristics

1.Heating oven could be opened by hydraulic,The guide roller in the oven was driving synchronous with host machine

2. HMI ,Man-machine face to face interface touch screen.

3. High precision auto edge position correction system, rewinding roll will have high precision edge neat

4. With inflammable gas detecting alarm (selected for solvent glue );

5. NON-Stop Machine station(Optional)

6. Double layers cycle drying oven, Both sides coating could be finished in One step. (Optional)

7. Each heating section is controlled independent. .

7. Current output type temperature control system makes heating quicker and electricity saving

8. Rewinding controlled by auto diminishing taper tension, it could avoid the materials damaged

9. Machine should be installed on firmly cement ground, need no special foundation, fix expansion bolt on key parts

2. HMI ,Man-machine face to face interface touch screen.

3. High precision auto edge position correction system, rewinding roll will have high precision edge neat

4. With inflammable gas detecting alarm (selected for solvent glue );

5. NON-Stop Machine station(Optional)

6. Double layers cycle drying oven, Both sides coating could be finished in One step. (Optional)

7. Each heating section is controlled independent. .

7. Current output type temperature control system makes heating quicker and electricity saving

8. Rewinding controlled by auto diminishing taper tension, it could avoid the materials damaged

9. Machine should be installed on firmly cement ground, need no special foundation, fix expansion bolt on key parts

Paramenters

|

Common matters

|

Raw material

|

PET, BOPP, PVC, PE, PI,Fabric ,Copper foil,Aluminum foil, etc., (User Advice)

|

|

|

Machine speed

|

100-150m/min below

|

|

|

Tasks speed

|

80-120m/min below

|

|

|

Raw material width

|

500~1800mm

|

|

|

Guide Roll

|

Φ100~120mm Anodizing or hard chrome surface treatment

|

|

|

Control motor

|

AC Vector Motor

|

|

|

Machine color

|

As required

|

|

Winder

|

Unwinding & rewinding part

|

2-axis turrent type or 1-axis center type

|

|

|

Reel outer Diameter

|

Φ600, Φ800, Φ1000, Φ1200mm

|

|

|

How to connect raw material

|

Automatic or manual connection

|

|

|

Splicing type and direction

|

Flying Arm(T/B), Tapeless(T/B)

|

|

|

Air-Shaft fixing type

|

3" Shaft + Adapter (AL or MC nylon)

|

|

Dryer

|

Chamber inner temperature

|

Max. 200°C

|

|

|

Hot blow injection type

|

Z-Nozzle

|

|

|

Heating source

|

Electric heater, gas burner, Thermal Oil, Strea heating

|

|

|

Unit Dryer length

|

1.8m, 2.2m, 3m, 4m

|

|

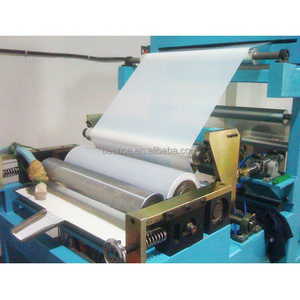

Coating Head

|

Developed unit

|

There are Comma, Gravure coating method .(Mayer bar could be fixed follow Users)

|

Detailed Images

Sample Show

Recommend Machines

Packing&Shipping

After Sales Service

Hot Searches