- Product Details

- {{item.text}}

Quick Details

-

Glass thickness:

-

3.2mm and 4.0mm±0.2mm

-

Warranty:

-

25 Years

-

Solar Transmittance:

-

>91.7 %

-

Iron Content:

-

<100ppm

-

Energy Transmittance:

-

Measurement aco.ISO9050:1990(E) and DIN67507/6.3

-

Density:

-

2.5 T/ CBM

-

Surface Finish:

-

Patterned One-sided /FLOATRoughness 0.4μm-1.0μm /0

-

Edge processing:

-

Grounded edges-shiny parts areallowed

-

Dimensional Tolerances:

-

±1.5mm

-

Hail stone test:

-

OK / NG

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

REOO

-

Model Number:

-

1948*976*3.2mm

-

Glass thickness:

-

3.2mm and 4.0mm±0.2mm

-

Warranty:

-

25 Years

-

Solar Transmittance:

-

>91.7 %

-

Iron Content:

-

<100ppm

-

Energy Transmittance:

-

Measurement aco.ISO9050:1990(E) and DIN67507/6.3

-

Density:

-

2.5 T/ CBM

-

Surface Finish:

-

Patterned One-sided /FLOATRoughness 0.4μm-1.0μm /0

-

Edge processing:

-

Grounded edges-shiny parts areallowed

-

Dimensional Tolerances:

-

±1.5mm

-

Hail stone test:

-

OK / NG

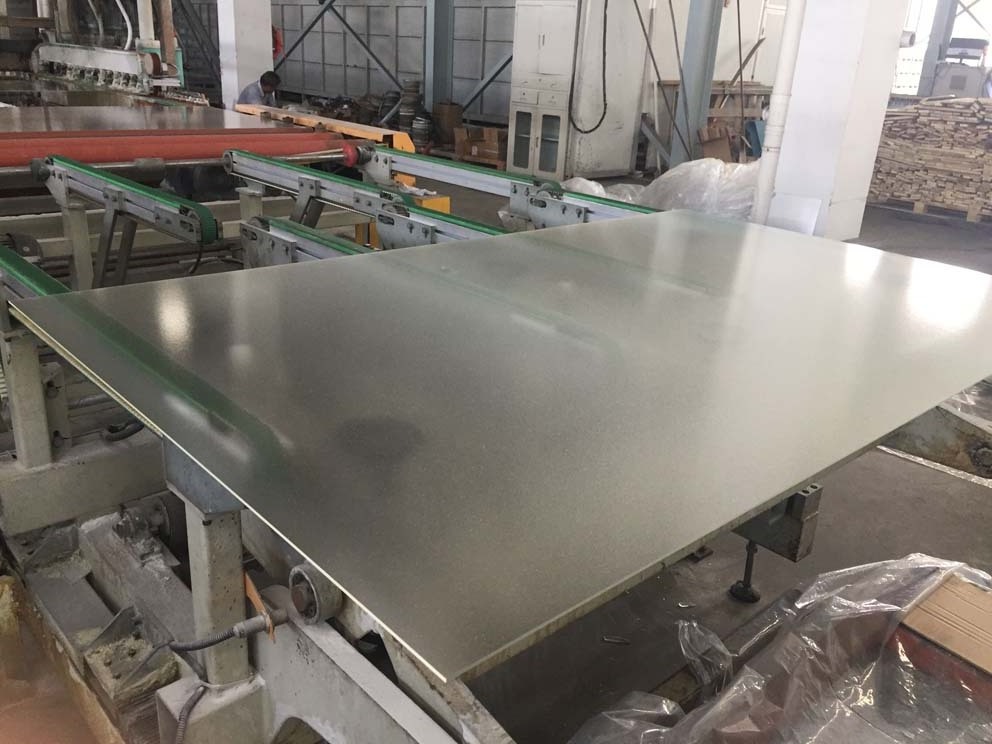

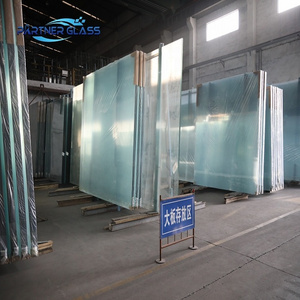

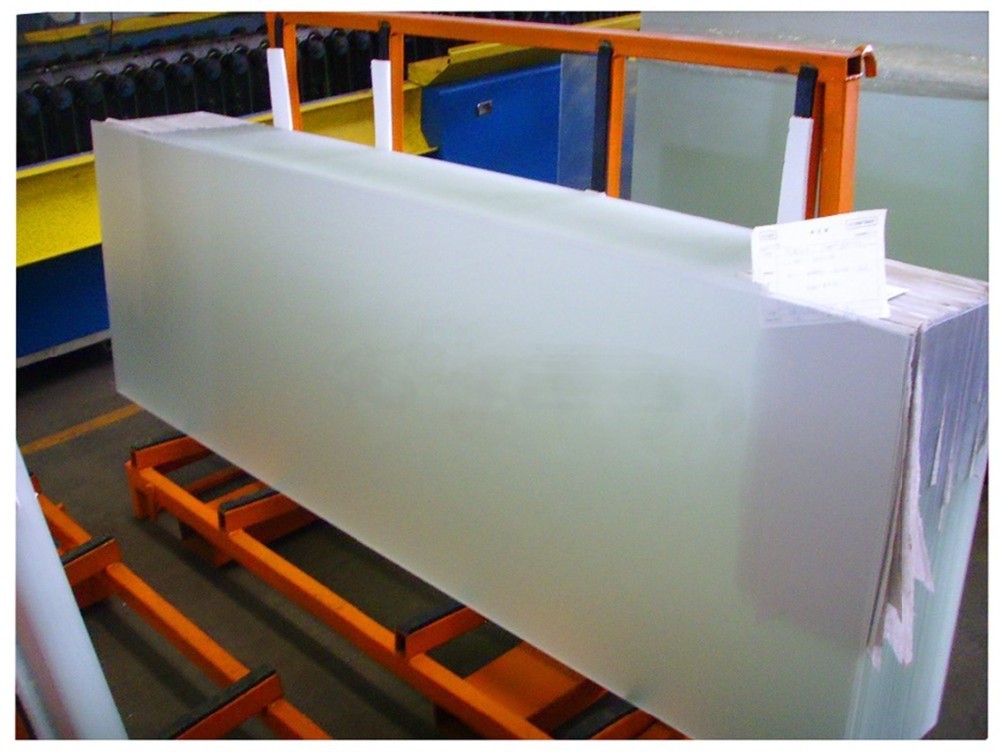

Solar panel tempered glass

Ultra white 3.2mm &4mm solar panel glass , are specially designed for encapsulation material of solar modules. The design reduces the direction reflectance and increase the internal reflection that the solar energy can be absorbed effectively. It ensures the maximum transmittance of the soar and raise the efficiency of electricity generation. The glass observes the properties of high solar transmittance, low absorbance, low reflectance, superior physical strength and significant flatness, is the ideal encapsulation material for solar thermal and photovoltaic modules.

Professional manufacture of AR ( Anti Reflective) solar glass which is mainly used solar collector,monocrystalline / polycrystalline photovoltaic / solar module and other energy products , display cabinets etc. our products are involved in solar glass, Photovoltaic/PV glass, anti-reflection solar glass, anti-reflection photovoltaic/PV glass anti-reflective solar glass

Functions:

1. High transmittance: 94-98%

For the same solar (PV) module, it can improve the power of more than 3% in the coated glass.

2. Self-cleaning function:

As the photovoltaic module is placed in the outdoor, easy to get dust, resulting in the decline in the power of the solar (PV) modules. Coated glass has the self-cleaning function which can ensure the normal operation of the solar(PV) module

3. Extend using circle:

Coated glass can effectively extend the service life (typically 25 years). Ensure the normal power generation of solar(PV) modules.

|

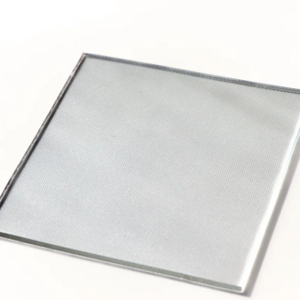

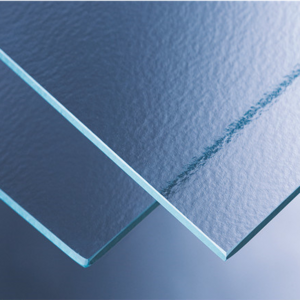

Properties |

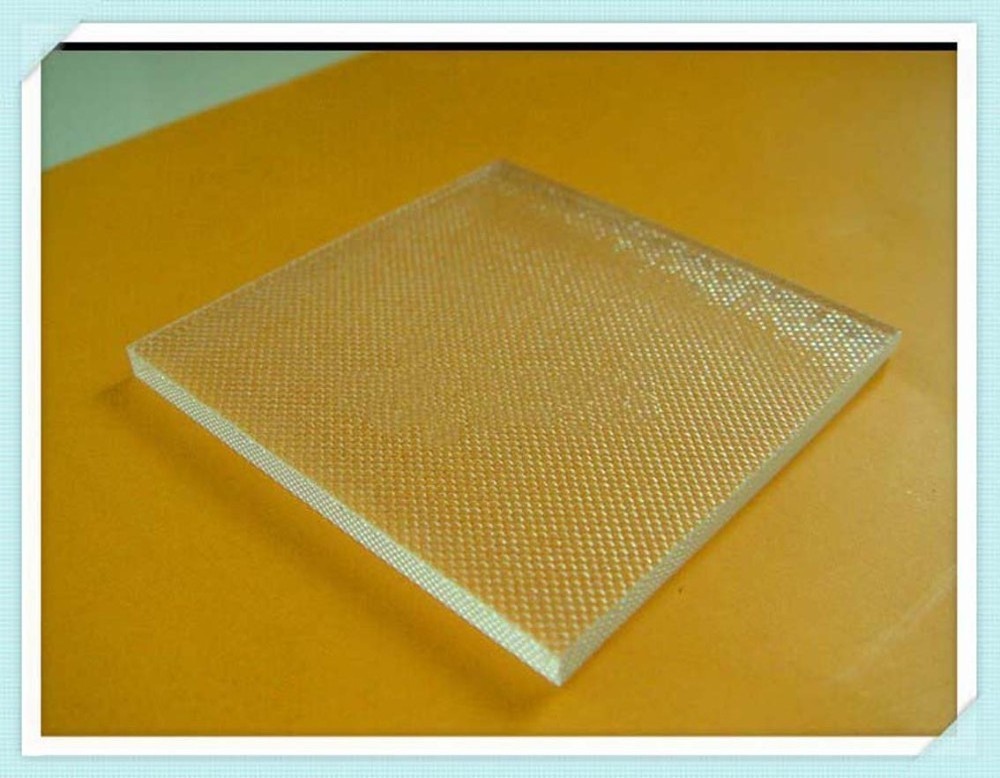

Patterned Solar Glass |

|||

|

Iron content |

≤ 0.010%Fe2O3 |

|||

|

Glass thickness |

3.2mm and 4.0mm±0.2mm |

|||

|

Energy Transmittance Te in%(±1%) Measurement aco.ISO9050:1990(E) and DIN67507/6.3 Factors aco.ISO9845/1(300-2500nm,AM1.5) |

3.2mm glass→91.6%±0.5% 4.0mm glass→91.5%±0.5% |

|||

|

Surface Finish |

Patterned One-sided /FLOAT Roughness 0.4μm-1.0μm /0 |

|||

|

Edge processing |

Grounded edges-shiny parts are allowed |

|||

|

Cut corners |

Maximum 3mm |

|||

|

Mechanical Resistance (DIN52303) |

90 N/mm 2 |

|||

|

Compressive Strength (DIN1249-10) |

>700 up to 900 N/mm 2 |

|||

|

Fragmentation (according to EN12150-1) |

Some small particles over the area 50×50mm |

|||

|

Shells L X W |

Maximum permissible 2×1mm |

|||

|

Thermal resistance (EN12150) |

Permanent temperature resistance up to 250 ℃ |

|||

|

Local Thermal Resistance |

Flat iron test (min.150℃ over ambient temperature) |

|||

|

Weight |

2.5×glass thickness in kg/m 2 |

|||

|

Max/Min Sheet-Dimensions |

3mm glass→max.2100mm×1660mm, min.200mm×250mm 4.0mm glass→max.2600mm×1660mm, min.200mm×250mm |

|||

|

Dimensional Tolerances |

±1.5mm |

|||

|

Rectangularity |

Diagonal difference max.1mm/m |

|||

|

Edge working |

Grounded with blank spots |

|||

|

Corner Cuts |

Max.3.0mm |

|||

|

Tolerances for Drilled Holes (grounded) |

±1.0mm |

|||

|

General Bow |

For 3mm glass thickness max.2.0mm/m For 4mm glass thickness max.1.5mm/m S-Bow and Frog-Effect is not permitted Convex side always on top/on front |

|||

|

Local Bow |

Max.0.35mm/300mm up to the edges 25mm from the edges for the rest of the surface →max.0.25mm/300mm Run direction is provided by customer |

|||

|

Glass quality per sheet: Test criteria(EN572-5:1994/5.1.1.1): Viewing distance 1.5m vertical to the sheet Parallel to a matt grey sheet at a distance of 3m in diffuse daylight |

Special Bubbles <1mm unlimited |

|||

|

Thermal Properties |

|

|

Hemispherical Emissivity At 0°-150°(-18°- 66℃) |

0.84 |

|

Expansion Coefficient (Linear in the range of 25℃ to 300℃) |

Per ℃=9.03×10 -6 Per °F=5.02×10 -6 |

|

Specific Heat at 32°-212°F (0°- 100℃) |

0.2 |

|

Calculated Thermal Conductivity at 20℃ in (watt/m 2 /K) |

1.04 |

|

Softening Point |

1332°F 722℃ |

|

Annealing Point |

1025°F 522℃ |

|

Strain Point |

932°F 500℃ |

MRS. Holly

NANTONG REOO TECHNOLOGY CO,. LTD

website: www.reoo.net

Add: Chennan industrial park, Juegang, Rudong, Jiangsu, China P.C.: 226400

Tel: +86-513-8410 5399 Fax: +86-513-8410 5505 Mobile: +86 13270815318

Skype: REOO Holly WhatsApp/ Wechat: 008613270815318