- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

Other

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine name:

-

Large stainless steel vacuum pug mill for ceramics factory

-

Power:

-

3Kw

-

Raw material:

-

Clay

-

Usage:

-

Large stainless steel vacuum pug mill for ceramics factory

-

Product name:

-

Large stainless steel vacuum pug mill for ceramics factory

-

Capacity:

-

2--3Tons/Hour

-

Application:

-

Large stainless steel vacuum pug mill for ceramics factory

-

Voltage:

-

220V/50HZ Or380V/60HZ

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

JINRI

-

Weight (KG):

-

3500

-

Core Components:

-

Other

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine name:

-

Large stainless steel vacuum pug mill for ceramics factory

-

Power:

-

3Kw

-

Raw material:

-

Clay

-

Usage:

-

Large stainless steel vacuum pug mill for ceramics factory

-

Product name:

-

Large stainless steel vacuum pug mill for ceramics factory

-

Capacity:

-

2--3Tons/Hour

-

Application:

-

Large stainless steel vacuum pug mill for ceramics factory

-

Voltage:

-

220V/50HZ Or380V/60HZ

PROFESSIONAL MANUFACTURER FOR CERAMIC TABLEWARE MACHINERY & KILNS

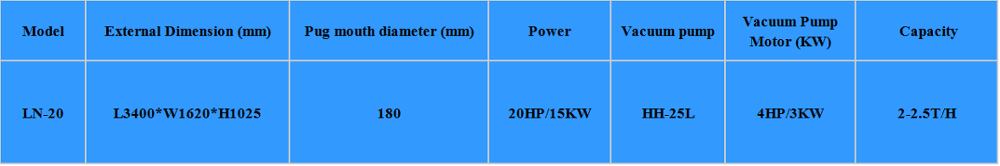

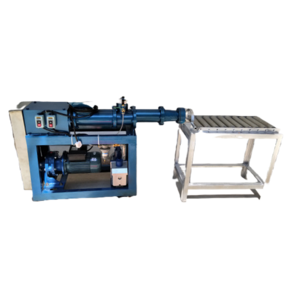

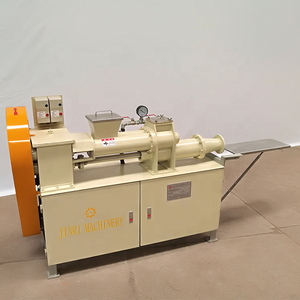

Large stainless steel vacuum pug mill for ceramics factory

1 .This pug mill is applicable to mix the clay for porcelain,fine pottery,bone china,stableware,artware etc;

2.The clay is fully cut and mixed, and passes screen through squeezing, then falls in the vacuum chamber in the fine-ground shape, and finally cut and discharged through squeezing.

3. Before the slog passes the screen and after the slog falls into the vacuum chamber, one vacuumize outlet is equipped respectively.

4.The mixing/squeezing system are precisely designed according to material balance principle, so as to ensure smooth charging, full mixing, reasonable squeezing, even density, high vacuum degree, strong plasticity and conformity to molding technique. The advantages are reasonable integral structure, strict control on quality of assembly, stable operation, small noises and long service life.