- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

BO YI DA

-

Outer Diameter:

-

20 - 100 mm

-

Thickness:

-

1-10mm

-

Grade:

-

Q235, Q238B, S275, S275jr, A53, st37, etc., Q195-Q235/st 37/52

-

Delivery Time:

-

7-35 day's

-

Product name:

-

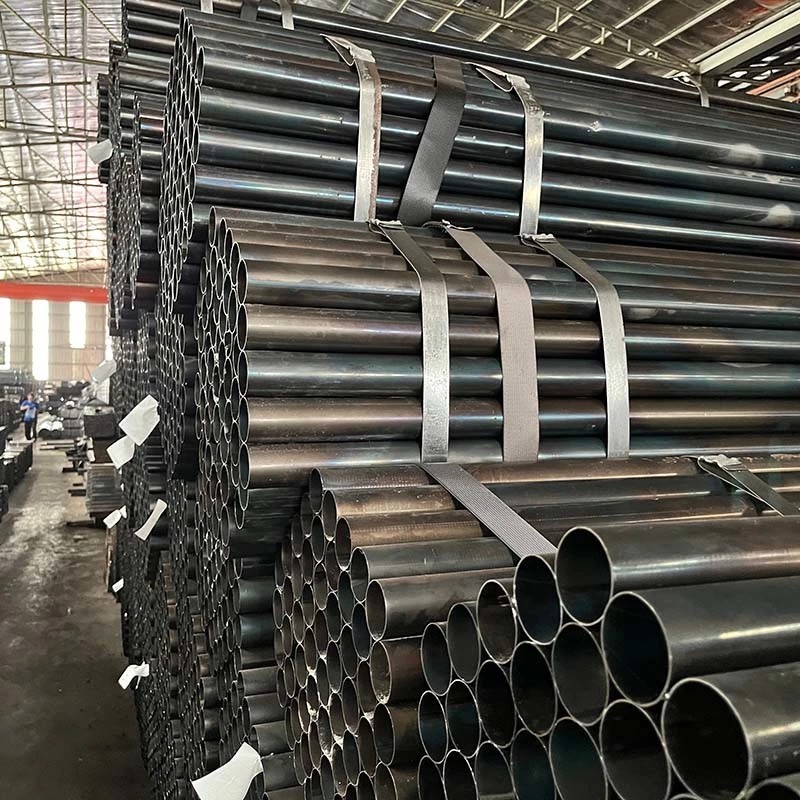

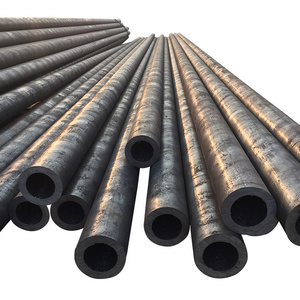

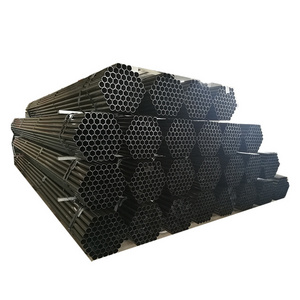

Black annealed steel tube

-

Material:

-

Q235, Q238B, S275, S275jr, A53, st37, etc.

-

Type:

-

Welded Steel Pipe

-

MOQ:

-

10 Tons

-

Keyword:

-

Steel Pipe Tube

-

Usage:

-

Construction Structure

-

Shape:

-

Round Tube Pipe

-

Surface:

-

Customers't Requirement

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Hot Rolled

-

Tolerance:

-

±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

BO YI DA

-

Outer Diameter:

-

20 - 100 mm

-

Thickness:

-

1-10mm

-

Grade:

-

Q235, Q238B, S275, S275jr, A53, st37, etc., Q195-Q235/st 37/52

-

Delivery Time:

-

7-35 day's

-

Product name:

-

Black annealed steel tube

-

Material:

-

Q235, Q238B, S275, S275jr, A53, st37, etc.

-

Type:

-

Welded Steel Pipe

-

MOQ:

-

10 Tons

-

Keyword:

-

Steel Pipe Tube

-

Usage:

-

Construction Structure

-

Shape:

-

Round Tube Pipe

-

Surface:

-

Customers't Requirement

Specifications:

1.Quality assurance: professional workers do inspection before shipment.

2.Delivery time: no need to waiting

3.Shipping: we choose the fastest vessel for you.

4.We can supply Best solutions for LCL containers loading.

Product introduction:

Black anneald tube seam welded pipe that is welded along its length. This pipes are often used to transport low-pressure fluids. The first form of production is that of a roll. The roll is rolled out and folded across the width to form a round shape. The seam is then welded, creating a longitudinal seam along its entire length. This is a continuous process until the roll is unwound and is common for standard diameters and thicknesses. The welding process for these tubes is called Longitudinally Submerged Arc Welded the second form of production is that of a steel plate. This plate is rolled into a pipe shape whose specification exactly fits the customer's project. These pipes are also welded along the length of the pipe and therefore also bear the name longitudinally welded.

Black anneald tube individually produced tubes have a limited length and therefore the elements are usually welded together by means of a circular seam. Seam welding is the process of joining work pieces made of similar or different materials along a continuous seam. Seam welding can be broken down into two main techniques, resistance seam welding and friction seam welding. This method is not limited in diameter and/or thickness and is therefore very suitable for projects with specific dimensions, for example with thick-walled pipes. The welding process for these tubes is called Double-sided Submerged Arc Welding. Longitudinally welded tubes are used for: posts, drilled posts, mooring posts fenders jetties.

Advantage:

The straight seam welded pipe is a circular straight seam welded pipe manufactured by a steel strip or steel plate from a steel mill through a press or a coiler, and then welded by secondary welding or submerged arc welding. The straight seam produced by this method Welded pipes can be called straight seam welded pipes. Compared with seamless steel pipes, longitudinal welded pipes have lower cost, higher production efficiency, and a wider range of machinable sizes and thicknesses. The blanks used are mainly steel plates. Longitudinal welded pipes have strong Corrosion resistance in acidic environments. From the perspective of being suitable for offshore oil and gas transportation, it is necessary to build longitudinal welded pipes. At present, a considerable part of oil and gas resources in the world are buried in the ocean. From the perspective of future natural gas development, they are mainly buried in the ocean in the form of "combustible ice". It is currently recognized that the total energy of "combustible ice" is 2-3 times that of all coal, oil, and gas, and it is the same in China, and it will be the main energy source in the future.