- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CS

-

Model Number:

-

product_01-07

-

most commonly used type:

-

C Type CONSTON

Quick Details

-

Material:

-

Stainless steel

-

Use:

-

Industrial

-

Place of Origin:

-

Japan

-

Brand Name:

-

CS

-

Model Number:

-

product_01-07

-

most commonly used type:

-

C Type CONSTON

Product Information

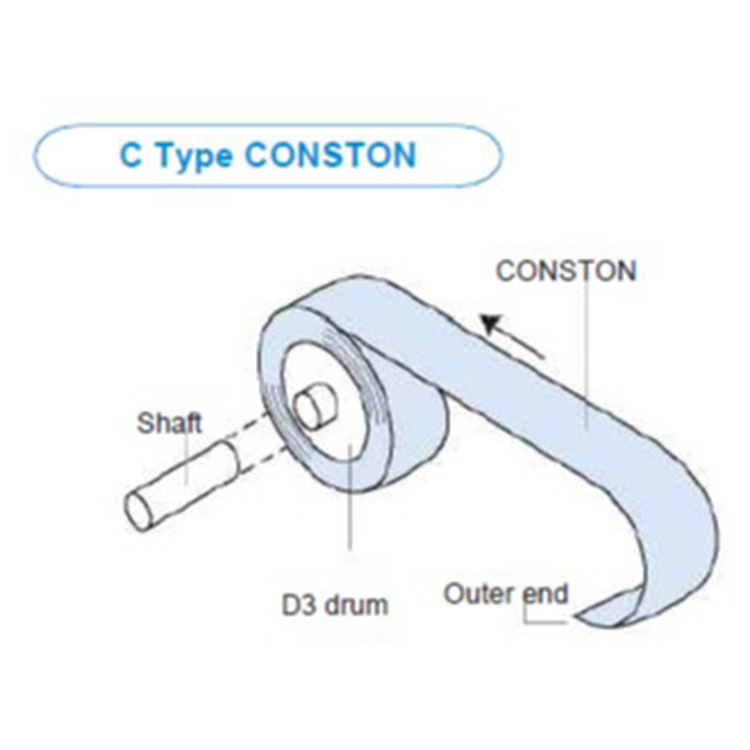

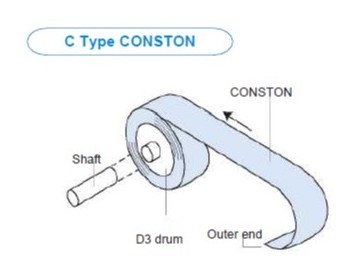

<C Type CONSTON>

This is the most commonly used type. When the CONSTON is pulled out, a force acts in the direction (←) to return to the original shape.

This returning force is utilized.

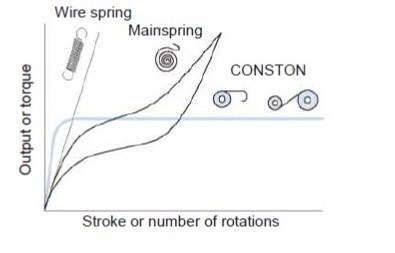

■The maximum output of the CONSTON spring is obtained at the point where it is pulled out by approx. a half or more turns from the drum.

■After reaching the maximum output, the output is unchanged, no matter how long the stroke is stretched.

■In contrast, the wire spring has a proportional relationship between the stroke and output; the longer the stroke,the stronger the force becomes.

■An ordinary wire spring requires its own space, but a CONSTON requires only a small installation space because the long spring fits in a small-diameter drum.

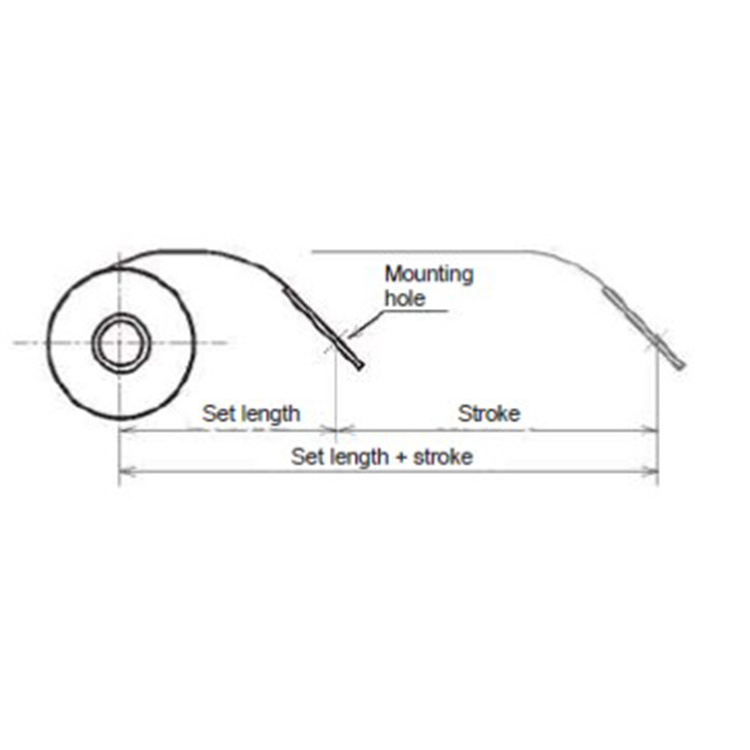

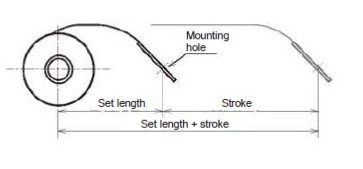

<Set length + stroke>

Basically, the “set length” is the length from which the CONSTON spring is pulled out by approx. a half or more turns from the drum.

The “stroke range” (repeated-operation range) begins with the “set length”; it must be used so that the total of “set length” plus “stroke” is within the specified range.

|

Model number

|

Output N (kgf)

|

Set length + stroke (mm)

|

Life (reference value) (times)

|

Tip mounting hole (mm)

|

|

Drum (mm)

|

|

|

|

|

|

|

Dia. φ

|

Pos. k

|

Φ a

|

|

|

CS0.05-1

|

0.49(0.05)

|

500

|

160000

|

3.2

|

5

|

26

|

|

|

CS 0.1-1

|

0.98(0.1)

|

500

|

50000

|

3.2

|

5

|

26

|

|

|

CS 0.2-1

|

1.96(0.2)

|

500

|

35000

|

3.2

|

5

|

26

|

|

|

CS 0.4-1

|

3.92(0.4)

|

1000

|

37000

|

4.5

|

8

|

34

|

|

|

CS 0.6-1

|

5.88(0.6)

|

1000

|

25000

|

4.5

|

8

|

34

|

|

|

CS 0.8-1

|

7.84(0.8)

|

1500

|

25000

|

4.5

|

8

|

34

|

|

|

CS 1.0-1

|

9.8(1.0)

|

500

|

6000

|

4.5

|

5

|

26

|

|

|

CS 1.0-2

|

|

1000

|

19000

|

4.5

|

8

|

38

|

|

|

CS 1.2-1

|

11.76(1.2)

|

1500

|

34000

|

4.5

|

8

|

44

|

|

|

CS 1.4-1

|

13.72(1.4)

|

1000

|

9000

|

4.5

|

8

|

34

|

|

|

CS 1.4-2

|

|

1000

|

33000

|

6.5

|

8

|

44

|

|

|

CS 1.6-1

|

15.68(1.6)

|

1500

|

17000

|

4.5

|

8

|

38

|

|

|

CS 1.8-1

|

17.64(1.8)

|

1500

|

9000

|

4.5

|

8

|

34

|

|

|

CS 2.0-1

|

19.6(2.0)

|

1000

|

6000

|

4.5

|

8

|

38

|

|

|

CS 2.0-2

|

|

1000

|

16000

|

4.5

|

8

|

44

|

|

|

CS 2.2-1

|

21.56(2.2)

|

1000

|

8000

|

4.5

|

8

|

44

|

|

|

CS 2.2-2

|

|

1000

|

19000

|

4.5

|

8

|

44

|

|

|

CS 2.4-1

|

23.52(2.4)

|

1000

|

6000

|

4.5

|

8

|

38

|

|

|

CS 2.6-1

|

25.48(2.6)

|

1000

|

9000

|

4.5

|

8

|

44

|

|

|

CS 2.9-1

|

28.42(2.9)

|

1000

|

6000

|

4.5

|

8

|

38

|

|

|

CS 2.9-2

|

|

1000

|

20000

|

6.5

|

8

|

54

|

|

|

CS 3.2-1

|

31.36(3.2)

|

1000

|

8000

|

4.5

|

8

|

44

|

|

|

CS 3.2-2

|

|

1000

|

7000

|

4.5

|

8

|

38

|

|

|

CS 3.5-2

|

34.3(3.5)

|

1000

|

7000

|

4.5

|

8

|

38

|

|

|

CS 3.5-3

|

|

1000

|

21000

|

6.5

|

8

|

54

|

|

|

CS 3.9-1

|

38.22(3.9)

|

1000

|

8000

|

4.5

|

8

|

44

|

|

|

CS 3.9-3

|

|

1000

|

17000

|

6.5

|

8

|

67

|

|

|

CS 4.3-1

|

42.14(4.3)

|

1000

|

8000

|

4.5

|

8

|

44

|

|

|

CS 4.7-2

|

46.06(4.7)

|

1000

|

9000

|

6.5

|

8

|

44

|

|

|

CS 5.2-1

|

50.96(5.2)

|

1500

|

6000

|

4.5

|

8

|

60

|

|

|

CS 5.2-2

|

|

1000

|

18000

|

6.5

|

8

|

70

|

|

|

CS 5.7-1

|

55.86(5.7)

|

1000

|

8000

|

6.5

|

8

|

44

|

|

|

CS 5.7-2

|

|

1500

|

12000

|

6.5

|

8

|

54

|

|

|

CS 5.7-3

|

|

1000

|

17000

|

6.5

|

8

|

67

|

|

|

CS 6.5-2

|

63.7(6.5)

|

1000

|

14000

|

6.5

|

8

|

95

|

|

|

CS 7.5-2

|

73.5(7.5)

|

1000

|

14000

|

6.5

|

8

|

95

|

|

|

CS 8.5-2

|

83.3(8.5)

|

1000

|

13000

|

6.5

|

8

|

95

|

|

|

CS10.0-2

|

98(10.0)

|

1000

|

13000

|

6.5

|

8

|

95

|

|

|

CS11.5-2

|

112.7(11.5)

|

1000

|

13000

|

6.5

|

8

|

95

|

|

|

CS13.0-2

|

127.4(13.0)

|

1000

|

14000

|

6.5

|

8

|

95

|

|

|

CS15.0-2

|

147(15.0)

|

1000

|

13000

|

6.5

|

8

|

95

|

|

|

Model number

|

Drum (mm)

|

|

|

Drum (mm)

|

Sub-plate width CONSTON width f (mm)

|

Bulge (reference value) SW (mm)

|

|||

|

Model number

|

Φ b

|

Φ c

|

Φ d

|

Φ e

|

Sub-plate width CONSTON width f (mm)

|

Bulge (reference value) SW (mm)

|

|||

|

CS0.05-1

|

17

|

18

|

5.2

|

8.2

|

10

|

-16

|

|||

|

CS 0.1-1

|

17

|

18

|

5.2

|

8.2

|

10

|

-16

|

|||

|

CS 0.2-1

|

17

|

18

|

5.2

|

8.2

|

10

|

-16

|

|||

|

CS 0.4-1

|

25.6

|

27.6

|

10.2

|

13

|

20

|

-18

|

|||

|

CS 0.6-1

|

25.6

|

27.6

|

10.2

|

13

|

20

|

-18

|

|||

|

CS 0.8-1

|

30.6

|

32.6

|

10.2

|

14

|

25

|

-18

|

|||

|

CS 1.0-1

|

17

|

18

|

5.2

|

8.2

|

13

|

-16

|

|||

|

CS 1.0-2

|

26.2

|

27.6

|

10.2

|

14

|

20

|

-21

|

|||

|

CS 1.2-1

|

40.6

|

42.6

|

10.2

|

14

|

35

|

-26

|

|||

|

CS 1.4-1

|

25.6

|

27.6

|

10.2

|

13

|

20

|

-18

|

|||

|

CS 1.4-2

|

45.6

|

47.6

|

10.2

|

16

|

40

|

-26

|

|||

|

CS 1.6-1

|

35.6

|

37.6

|

10.2

|

16

|

30

|

-21

|

|||

|

CS 1.8-1

|

30.6

|

32.6

|

10.2

|

14

|

25

|

-18

|

|||

|

CS 2.0-1

|

26.2

|

27.6

|

10.2

|

14

|

20

|

-21

|

|||

|

CS 2.0-2

|

35.6

|

37.6

|

10.2

|

14

|

30

|

-26

|

|||

|

CS 2.2-1

|

25.6

|

27.6

|

10.2

|

14

|

20

|

-26

|

|||

|

CS 2.2-2

|

40.6

|

42.6

|

10.2

|

14

|

35

|

-26

|

|||

|

CS 2.4-1

|

30.6

|

32.6

|

10.2

|

14

|

25

|

-21

|

|||

|

CS 2.6-1

|

30.6

|

32.6

|

10.2

|

14

|

25

|

-26

|

|||

|

CS 2.9-1

|

35.6

|

37.6

|

10.2

|

16

|

30

|

-21

|

|||

|

CS 2.9-2

|

46

|

49

|

10.2

|

16

|

40

|

-32

|

|||

|

CS 3.2-1

|

35.6

|

37.6

|

10.2

|

14

|

30

|

-26

|

|||

|

CS 3.2-2

|

40.6

|

42.6

|

10.2

|

14

|

35

|

-21

|

|||

|

CS 3.5-2

|

43.6

|

45.6

|

10.2

|

16

|

38

|

-21

|

|||

|

CS 3.5-3

|

56

|

58

|

10.2

|

16

|

50

|

-33

|

|||

|

CS 3.9-1

|

40.6

|

42.6

|

10.2

|

14

|

35

|

-26

|

|||

|

CS 3.9-3

|

47

|

49

|

10.2

|

16

|

40

|

-41

|

|||

|

CS 4.3-1

|

43.6

|

45.6

|

10.2

|

16

|

38

|

-26

|

|||

|

CS 4.7-2

|

50.6

|

52.6

|

10.2

|

14

|

45

|

-26

|

|||

|

CS 5.2-1

|

37

|

40

|

10.2

|

16

|

30

|

-36

|

|||

|

CS 5.2-2

|

56

|

59

|

10.2

|

16

|

50

|

-48

|

|||

|

CS 5.7-1

|

55.6

|

57.6

|

10.2

|

14

|

50

|

-26

|

|||

|

CS 5.7-2

|

56

|

58

|

10.2

|

16

|

50

|

-33

|

|||

|

CS 5.7-3

|

67

|

69

|

10.2

|

16

|

60

|

-41

|

|||

|

CS 6.5-2

|

47

|

49

|

10.2

|

16

|

40

|

-60

|

|||

|

CS 7.5-2

|

57

|

59

|

10.2

|

16

|

50

|

-60

|

|||

|

CS 8.5-2

|

57

|

59

|

10.2

|

16

|

50

|

-60

|

|||

|

CS10.0-2

|

67

|

69

|

10.2

|

16

|

60

|

-60

|

|||

|

CS11.5-2

|

77

|

79

|

10.2

|

16

|

70

|

-60

|

|||

|

CS13.0-2

|

87

|

89

|

10.2

|

16

|

80

|

-60

|

|||

|

CS15.0-2

|

97

|

99

|

10.2

|

16

|

90

|

-60

|

|||

Hot Searches