- Product Details

- {{item.text}}

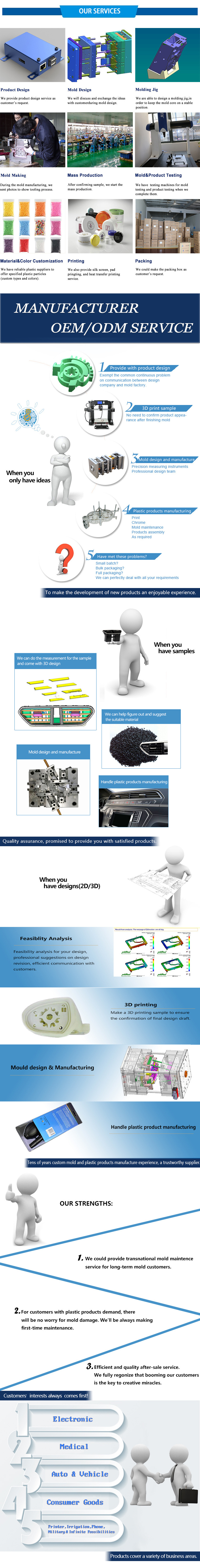

Quick Details

-

Brand Name:

-

FutureMould

-

Model Number:

-

FQ180134

-

Car Make:

-

Universal

-

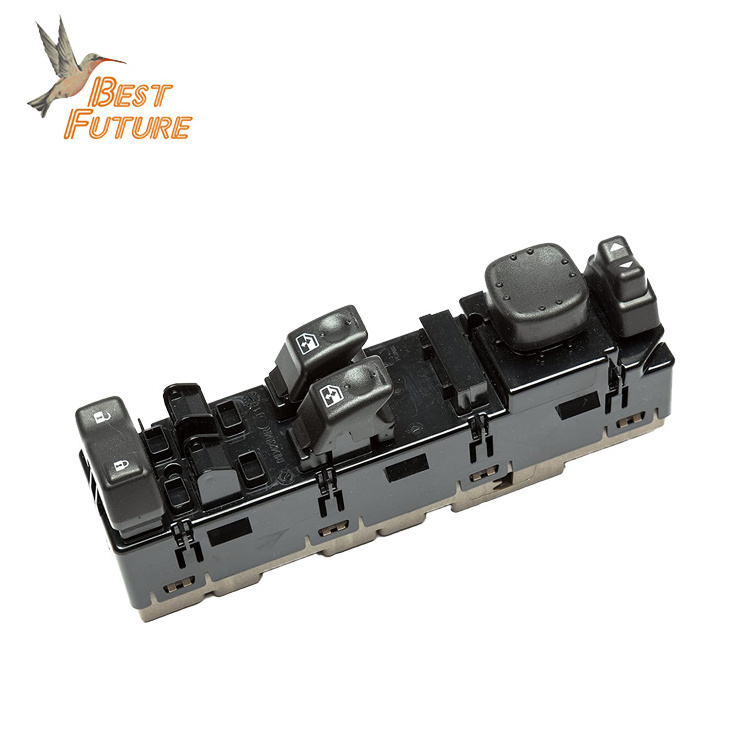

Product name:

-

Car Door Window Lifter Switch

-

Color:

-

Customized

-

Weight:

-

Customized

-

Dimension:

-

Customized

-

Surface treatment:

-

Texture/Polishing

-

Application:

-

Automotive Parts

-

Packing:

-

Customized

-

MOQ:

-

200pcs

-

Delivery time:

-

15-45 Days

-

Service:

-

OEM\ODM

Quick Details

-

OE NO.:

-

OEM Customized

-

Warranty:

-

12 Months

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

FutureMould

-

Model Number:

-

FQ180134

-

Car Make:

-

Universal

-

Product name:

-

Car Door Window Lifter Switch

-

Color:

-

Customized

-

Weight:

-

Customized

-

Dimension:

-

Customized

-

Surface treatment:

-

Texture/Polishing

-

Application:

-

Automotive Parts

-

Packing:

-

Customized

-

MOQ:

-

200pcs

-

Delivery time:

-

15-45 Days

-

Service:

-

OEM\ODM

Front Door Lock and Side Window Switch with Mirror Switch and Module

|

Product Name |

Front Door Lock and Side Window Switch with Mirror Switch and Module |

|

Plastic Material |

ABS, ASA, PA-60GF, PBT, PC,PC/ABS, PE,PEI, HDPE, PMMA, PPS, PEEK, etc. |

|

Weight |

Custom |

|

Size |

Custom |

|

Surface Treatment |

Polishing finish, Texture finish, Glossy finish, Painting, Slik printing, Rubber Painting, etc. |

|

Custom |

Custom manufacturing according to customer's drawings or samples |

|

MOQ |

At least 100 units if mass production needed |

|

Packing |

Poly bag, Carton box |

|

Lead Time |

25-40days |

|

Mold Type |

Injection Mold |

|

Mold Cavity |

Single or Multi |

|

Mold Base |

LKM; HASCO; DME; etc. |

|

Core Steel |

P20, LKM738, H13, S416, 1.2083,1.2085, 1.2311,1.2312,1.2343ESR, 1.2767, NAK80, etc. |

|

Mold Gate |

Fan Gate, Sub Gate, Pin Point Gate, Valve |

|

Runner |

Cold runner, Hot runner |

|

Mold Steel Tolerance |

+/-0.05mm |

|

Mold Life |

100k-1,000k shots |

|

Injection Molding Machine |

Horizontal, Vertical |

|

MOQ |

1 set |

|

Design Sofrware |

UG, PROE, CAD, SOLIDWORK, etc |

Q: How do I know if injection molding is the right process for my product?

-More often than not, part complexity will dictate whether you need to use one process or the other. Parts that can be pressed into the desired shape can be accomplished through compression molding. Parts that are more complex, that have features that require a more sophisticated mold and will be more repetitive in its' production cycle are better injection molded.Q: How do I know if injection molding is the right process for my product?

Q: Do you design plastic injection parts?

-FutureMould does component part design. We have professional product designers that design a part that meets your functional needs and has been optimized for mold design and moldability.

Q: What type of information is required for quoting a molding project?

-We do want to evaluate the part using a 3D file output from any number of designing software packages, e.g. STP, IGS, STL, X_T, UG, PROE, CAD, SolidWorks or others.

Q: What part size limitations do you have?

-Physical size is based on surface area. Our presses range from 55 Tons to 1300 Tons, mold sizes from the size of your hand to almost 2ft x 2ft x 3ft and can shoot pea sized parts up to 18in x 18in.

Q: Do you design and make all of the new molds used at FutureMould?

-Molds reside at FutureMould under numerous development scenarios. Most of the molds here were both designed and built by FutureMould. We feel this gives our customer the best advantage for shortest lead times and time to market.

Q: What resin should I use for my project?

-That is totally dependent on the end use application for your part. Once we discuss your part and its design requirements specification, we can assist you in your selecting a suitable plastic or composite.

Q: How long does it take to build an injection mold?

-Depending on size and complexity, 4 to 6 weeks generally.

Q: What types of molding services do you offer?

-We are a plastic injection molder that performs insert molding, over-molding, jig service, and in-mold decorating.

Q: Do you offer extended molding services such as assembly, packaging, or decorating?

-We routinely provide assembly work, ultrasonic welding, heat staking, CNC machining, pad printing, and packaging options.

Q: Do you design and build molds?

-Yes, we consider it an advantage that we both design and build our customers' molds and then shoot the production parts under the same roof. It makes for a much more smooth process in getting a mold up and running in production.

Q: Do you outsource mold design and build oversea?

-Yes, FutureMould does almost all mold business oversea. We have found over 15 years that our pricing and lead times are equivalent and always better than the final cost of your domestic companies.

Q: How much does a mold cost?

-A mold can be as little as $1,000 to as much as $100,000.

Q: Can you mold around inserts or metal components?

- Yes, we routinely perform insert molding. We have designs calling for just a few to as many as 40 inserts placed in the mold prior to the shot.