- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

customize

-

Voltage:

-

220-440V as request

-

Dimension(L*W*H):

-

to be specified

-

Year:

-

2024

-

Weight (KG):

-

8000 kg

-

Power (kW):

-

44

-

Name:

-

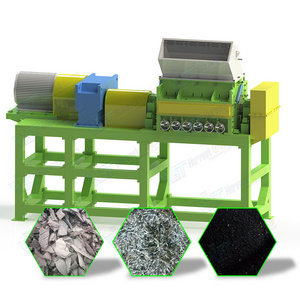

tire shredding tire steel wire separator tire recycling equipment

-

Double shaft tire shredder:

-

shred whole tire to rubber chips

-

Motor:

-

Siemens

-

Output size from rubber mulch system:

-

10-30mm rubbrer mulch

-

Advantage:

-

Advance technology

-

Machine Type:

-

Siemens PLC control system fully automatic tire recycling line

-

Machine color:

-

Blue or as request

-

Electronic component of recycling line:

-

shneider electronic component

-

Application of rubber mulch:

-

playgroud , landscape ,training course,turf infill,etc

-

Key word:

-

Rubber Shredding Production Line

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

LIKE

-

Marketing Type:

-

New Product 2024

-

Model Number:

-

customize

-

Voltage:

-

220-440V as request

-

Dimension(L*W*H):

-

to be specified

-

Year:

-

2024

-

Weight (KG):

-

8000 kg

-

Power (kW):

-

44

-

Name:

-

tire shredding tire steel wire separator tire recycling equipment

-

Double shaft tire shredder:

-

shred whole tire to rubber chips

-

Motor:

-

Siemens

-

Output size from rubber mulch system:

-

10-30mm rubbrer mulch

-

Advantage:

-

Advance technology

-

Machine Type:

-

Siemens PLC control system fully automatic tire recycling line

-

Machine color:

-

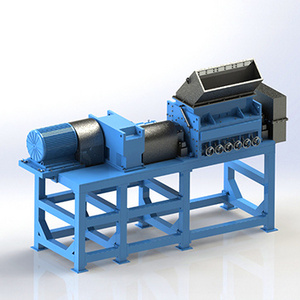

Blue or as request

-

Electronic component of recycling line:

-

shneider electronic component

-

Application of rubber mulch:

-

playgroud , landscape ,training course,turf infill,etc

-

Key word:

-

Rubber Shredding Production Line

Rubber mulch making system

This is the second step in the tire recycling line.

It is designed for remove wire steel from tire, and process rubber chips from tire shredder into 10-30mm rubber mulch as designed.

Main Features

1) Siemens PLC control system tire recyclig line

2) High quality design,advanced technology

3) Processing blades, shafts, parts,etc

4) Famous brand motor

Tire shredder

Type: double shaft

Motor: siemens

Original: China

To shred the waste tire into rubber chips as required size

Rasper

Motor:

Siemens

To remove steel from tire, and shred the rubber blocks into rubber mulch 10-30mm as request

The whole tire recycling milling production line includes tire shredder, rasper, granulator and miller system, etc

Each step, you will get different size of rubber raw material as your requirement.

The customize service will be provided for every customers based on your specific capacity requirement, tire, size, etc

1) Are you a factory or trade company?

We are professional recycling line machine factory, professional design engineer, experienced production team, advanced manufacturing and processing facility. You can get good technical support from us.

2) How can I trust your company?

a. famous brand component as our standard configuration, like Siemens Motor, Tongli or SEW reducer, Siemens PLC and Schneider component. All parts use high quality material and precise processing .

b. Assessed by third party-national test centre. national patents,SGS, CE, ISO certificate

c. Welcome to visit our factory to check at any time

3) How about the test running & installation?

Before delivery, welcome you to come to testing all machines in our factory.

Before shipping out your machines, we will invite you to come to test your machines, when you are satisfied; we start to pack and delivery.

We will dispatch our enginne to your country to help you to install and debug the machine, as well as training your workers.

4) How about the warranty?

Under the proper usage, 1-3 year for whole machine, we provide long-time after sales service for our customer.

Before-sales service:

1. Technical proposal

2. Answer questions within 8 hours

3. Tested machine

After-sales service:

1. Install and debug machine, train workers

2. Free spare parts within gurantee period

3. Long time technical support when production process