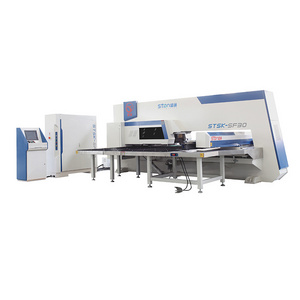

The SF model can be upgraded with our Ultra Package which can decrease part processing times by up to 40%.

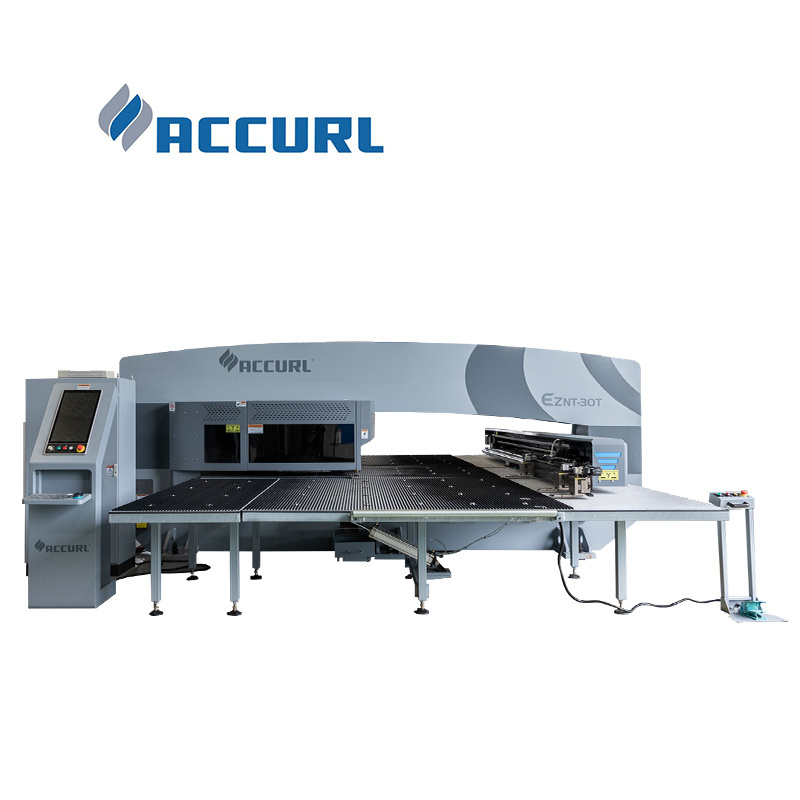

The ACCURL comes standard with the following features:

Automatic Tool and Linear Components Lubrication System

Pneumatic Ball Transfer and Brush Table for ease of loading/unloading

Vacuum Assist System for slug removal

32 Stations 2 Auto indexing stations

One Mirror-Type Safety System to guard entire work envelope

Man-Sensors on moving tables

Sheet Jam Protectors to detect warped material

Sheet-gripper sensors to detect loose material

Pneumatic Ball Transfer and Brush Table for ease of loading/unloading

Vacuum Assist System for slug removal

32 Stations 2 Auto indexing stations

One Mirror-Type Safety System to guard entire work envelope

Man-Sensors on moving tables

Sheet Jam Protectors to detect warped material

Sheet-gripper sensors to detect loose material