- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

0

-

Size:

-

0

-

Power:

-

0

-

Weight (KG):

-

1 kg

-

Application:

-

Wastewater Treatment

-

Capacity:

-

0.3-200000T/H

-

Function:

-

Filtering Suspended Matter

-

Usage:

-

Seawater Ionizer Desalination

-

Type:

-

RO Water Treatment Plant

-

Certification:

-

ISO9001:2008

-

Processing:

-

Industry Waste Water Etc

-

Membrane area:

-

20 m2

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

FLUFILT

-

Material:

-

0, plastic / stainless steel

-

Weight:

-

0

-

Size:

-

0

-

Power:

-

0

-

Weight (KG):

-

1 kg

-

Application:

-

Wastewater Treatment

-

Capacity:

-

0.3-200000T/H

-

Function:

-

Filtering Suspended Matter

-

Usage:

-

Seawater Ionizer Desalination

-

Type:

-

RO Water Treatment Plant

-

Certification:

-

ISO9001:2008

-

Processing:

-

Industry Waste Water Etc

-

Membrane area:

-

20 m2

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

| Disc aerator |

The disc microporous aerator consists of a rubber diaphragm, several air diversion slots, a chassis support, and a screw gland. Made of imported rubber raw materials made of diaphragm mounted on the chassis bracket. The chassis bracket is a diaphragm support and is arched. The upper part of the chassis support is provided with eight air diversion slots distributed around the center to ensure that the air is evenly separated. The screw gland is screwed on the bottom part of the chassis support to screw with the chassis support, and the diaphragm is fixed on the chassis support. The chassis support and screw cover are injection molded from high quality ABS engineering plastic.

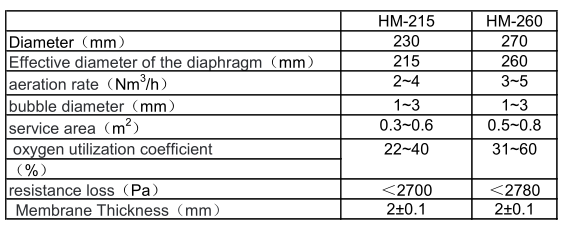

Technical parameters

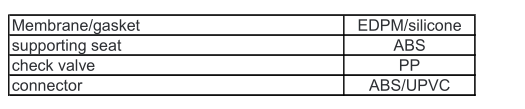

Material

Feature

This product uses high-tech CNC knife hole technology, which brings three major benefits; seal impermeability, tear resistance, long life, anti-surface adhesion to avoid clogging.

The surface of the inner substrate disc is provided with a plurality of air guide grooves to ensure that the outgassing rate of the aeration panel reaches 100%, and the aeration resistance of the aerator is greatly reduced.

Diaphragm and inner substrate plate and tight ring are screwed mechanical assembly to ensure that the film never falls off.

The unique technology built-in check valve, which is based on a variety of models on the market to overcome the technical difficulties, newly developed unique products, and has applied for national invention patents. Effectively solve the aerator backflow phenomenon.

Oxygen utilization is high and resistance is low.

Accessories and components

Different conditions can use different diaphragms:

EPDM diaphragms with low plasticizers are used for municipal wastewater containing industrial wastewater and industrial wastewater containing small amounts of greases and hydrocarbons. The maximum temperature of 80 °C is allowed.

Silicone rubber diaphragms are suitable for industrial wastewater containing more grease and hydrocarbons. The maximum temperature of 100 °C is allowed.

Connector with preformed hole

Install

The installation of the aeration system should be installed by installing the system plan and installation drawings. The center of the gas manifold is about 145~165mm from the bottom of the tank, allowing a horizontal height error of ±10mm. The surface of the aerator is approximately 230m to 250mm from the bottom of the tank, and the error of the center of the chassis and the tube after installation of the aerator is no more than 5mm.