- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 50HZ

-

Power:

-

16KW

-

Dimension(L*W*H):

-

7150* 3150* 2000 (L*W*H)

-

Weight:

-

8000

-

Power Supply:

-

380V, 50HZ

-

Motive Factor:

-

16 KW

-

Suitable Material:

-

Spun-lace non-woven fabrics, Hot-rolling non-woven fabrics.

-

Production Speed:

-

3200-3600 pcs/min

-

Raw Material Size:

-

1000-1500mm

-

Folding Way:

-

Longgitudinal Z-folded. Pop up or Non pop up

-

Counting Way:

-

Auto-counting, quantity changeable pile system

-

Control System:

-

PLC control system, color touching screen

-

Machine Size (mm):

-

7150* 3150* 2000 (L* W* H)

-

Weight of Machine (kg):

-

8000 KG

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

CND

-

Marketing Type:

-

New Product 2023

-

Voltage:

-

380V, 50HZ

-

Power:

-

16KW

-

Dimension(L*W*H):

-

7150* 3150* 2000 (L*W*H)

-

Weight:

-

8000

-

Power Supply:

-

380V, 50HZ

-

Motive Factor:

-

16 KW

-

Suitable Material:

-

Spun-lace non-woven fabrics, Hot-rolling non-woven fabrics.

-

Production Speed:

-

3200-3600 pcs/min

-

Raw Material Size:

-

1000-1500mm

-

Folding Way:

-

Longgitudinal Z-folded. Pop up or Non pop up

-

Counting Way:

-

Auto-counting, quantity changeable pile system

-

Control System:

-

PLC control system, color touching screen

-

Machine Size (mm):

-

7150* 3150* 2000 (L* W* H)

-

Weight of Machine (kg):

-

8000 KG

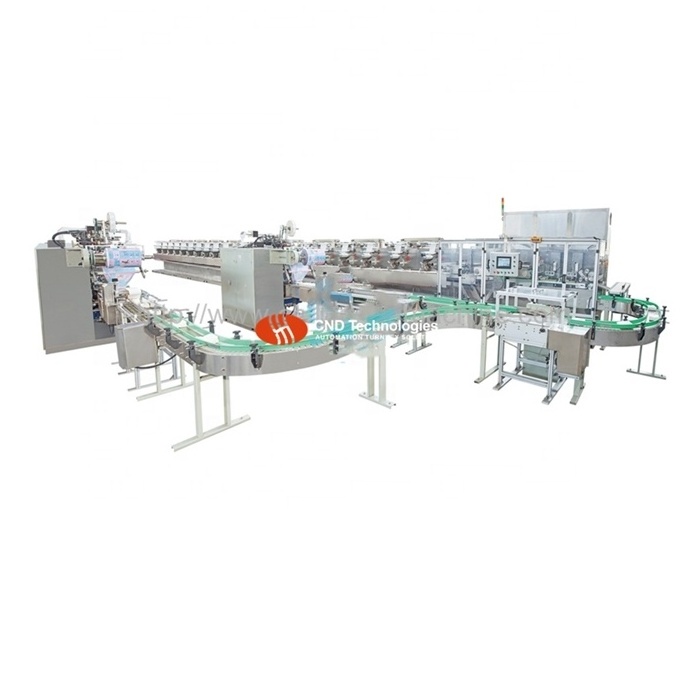

CND-2000 full automatic 20-120 pcs wet tissue machine

(With and without pop-up)

Main technical parameter of the folding part + Packing part

|

Model

|

Main technical parameter of the folding part

|

|

|

|

NO.

|

Item

|

Technical Specification

|

|

|

1

|

Motive Factor

|

16KW

|

|

|

2

|

Power Supply

|

380V, 50HZ

|

|

|

3

|

Suitable Material

|

Spun-lace non-woven fabrics, Hot-rolling non-woven fabrics

|

|

|

4

|

Production Speed

|

3200-3600pcs/min

|

|

|

5

|

Sheets in one bag

|

20-150sheets, can be changeable

|

|

|

6

|

Raw Material Size

|

1000-1500mm

|

|

|

7

|

Folding Way

|

longgitudinal Z-folded. Pop up or Non pop up

|

|

|

8

|

Counting Way

|

Auto-counting, quantity changeable pile system

|

|

|

9

|

Humidification Agitating System

|

Double agitating drums with agitator

|

|

|

10

|

Control System

|

PLC control system, color touching screen

|

|

|

11

|

Machine Size (mm)

|

7150* 3150* 2000 (L* W* H)

|

|

|

12

|

Liquid Tank Capacity

|

600 liter, 2tank

|

|

|

13

|

Water Tank Size (mm)

|

2000* 100* 1900; 250KG

|

|

|

14

|

Weight of machine (KG)

|

8000KG

|

|

|

15

|

Efficiency

|

>=95%

|

|

|

16

|

Wastage

|

<=2%

|

|

|

17

|

Option (Should add extra cost)

|

Glue machine, 90 degree or U Turn corner for the connect of folding machine and packing machine.

|

|

|

Model

|

Packing part

|

|

|

|

|||

|

NO.

|

Item

|

|

Technical Specification

|

|

|||

|

1

|

Electrical Source

|

|

380V 50HZ

|

|

|||

|

2

|

Power

|

|

11KW

|

|

|||

|

3

|

Production Speed

|

|

30~80 packs/min

|

|

|||

|

4

|

Product Size

|

|

(180~300)× (90~120)× (30~80)mm

or (140~220)× (70~100)× (10~30)mm (L*W*H) ( It is needed to change the mould when you want to change the size.) |

|

|||

|

5

|

Control System

|

|

Adjustable motion control system,PLC control,color touch screen

|

|

|||

|

6

|

Suitable Material

|

|

OPP/PE,PET/PE

|

|

|||

|

7

|

Weight of Machine

|

|

1900 KG

|

|

|||

|

8

|

Machine Size

|

|

5280* 1300* 2000mm (L* W* H)

|

|

|||

|

9

|

Packing Method

|

|

Reciprocating type packing machine with gusset-insert,

( If need hanger-hook unit, it is optional). |

|

|||

|

|

Option: protection label mechanism

1. The length of product can be setted on the color touch screen, easy to operation. 2. Trepanning position, label position can be adjusted on the touche screen, it can avoid the change of position caused by mechanical structure adjustment. 3. The whole machine control by servo motor drive, make it operate stable with lower noise, high speed and precision. 4. The machine including date printing unit, it is convenient for printing produce date and batch number. 5. Stationary type bag machine unit, easy for adjustment. Equipped with adjustable bag machine unit, can change different product sizes when needed. |

|

|

|

|||

* When the equipment is shipped, we will provide you with some wearing parts for free to ensure the normal operation of the equipment.

* After the equipment leaves the factory, we will provide one year of after-sales service. During this period, due to the failure of the design of the equipment, we will replace the parts for you for free.

If the electrical parts have quality problems, we will replace them for free within one year.

* After one year, we will continue to provide after-sales service.

If wearing parts and other parts need to be replaced, we will only charge for the cost.

Tissue Packing Line

PJ V Fold Production Line

Robot

Use Robot

Working

Kitchen T owel

Kitchen Towel

Production Line

Tissue Production

CND-200MJ + CND FZ15

Tissue Production Line

Kitchen Towel Packing Line

Kitchen Towel 1Roll/2Roll Packing

Paper Production Line

Toilet paper

+ Jomboo Roll + Tissue Production Line

Tisseu Converting Machine

YD, YC, YH, PF, MJ, BJ, ULTRA

Automatic Jumboo Roll Rewinder

Ultra-SR600,

Ultra-SR1200

Embossed Facial Foldes

YH-2L, YH-4L, YH-5L,

YH-6L

Towel Folders

MJ-N-3L, MJ-N-4L,

MJ-N-5L

Slitting Rewinder

PF-A, PF-E

Full Automatic Tissue Rewinder Line

Ultra-YD-E-3,Ultra-YD-E-4, Ultra-YD-E-5

CND company is located in Dalian, China. Dalian is one of the most important international port cities in China and the international logistics center in east Asia.

CND focuses on design, R&D, production of industrial equipment and automatic equipment, and is committed to creating and providing a solution platform for the most professional automatic equipment, production line integration. CND can provide a technological package of specialized solutions and service process, especially in industrial equipment, household paper equipment, packaging equipment, protective equipment, new energy field etc.

CND has a wide range of service outlets at home and abroad, and has offices and after-sales service centers in South Korea and other countries, is recognized widely by domestic and foreign customers over the years. CND hopes to cooperate with you to create a better future.

Q1

:

How long does it take to produce the equipment?

A : Generally, it takes 25-60 days for small equipment and documents; and 90-120 days for production lines or large equipment.

Q2 : How to install the equipment after arrived? Will your company send us a technician?

A : Generally, it takes 25-60 days for small equipment and documents; and 90-120 days for production lines or large equipment.

Q2 : How to install the equipment after arrived? Will your company send us a technician?

A

: Sure, we will apply for a working visa for our technician while the equipment is shipped,then we will set out for the specific location of its country for equipment installation.

We will take videos of the equipment installation and operation, and offer you the equipment manual If our technician is unable to go under the exceptional circumstances (epidemic situation, visa rejection, isolation, etc.)

Q3

:

Can I put my Logo/ Brand on the machines and finish products?

A

:

Sure

, please just send us your artworks.

Q4

:

How can we know the quality of your machine?

A

: Customers can send material to us and then we use our machine to manufacture finished products which will be re-sent to customers.

Q5

:

Do you have after sale service?

A

: Yes, we provide one year warranty and technical support.

Q6

:

What if we can't come for inspection after the equipment is finished under special circumstances

(epidemic situation, visa rejection, isolation, etc.)?

A

: We will provide you with taking the complete commissioning video and pictures of the equipment.

Hot Searches