- Product Details

- {{item.text}}

Quick Details

-

Positioning Accuracy (mm):

-

0.03 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

4000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.03 mm

-

Spindle Motor Power(kW):

-

6kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Blue Elephant

-

Voltage:

-

AC380V(Option)

-

Dimension(L*W*H):

-

2000x4000x200mm

-

Power (kW):

-

7.5

-

Weight (KG):

-

1500

-

Model:

-

ELECNC2040

-

Control system:

-

Ncstudio DSP A11, option: Taiwan SYNTEC /LNC controller

-

Driving system:

-

Stepper motor and Leadshine driver, option: Japan YASAKWA Ac servo

-

Work table:

-

Aluminum T-slot & vacuum work table

-

Traveling speed:

-

80m/min

-

Working speed:

-

0-25m/min

-

Re-positioning accuracy:

-

±0.03mm

-

System resolution:

-

±0.0025mm

-

Working accuracy:

-

±0.03mm -

-

Working voltage:

-

220V 1PH/3PH 50HZ/60HZ 380V 3PH 50HZ/ 60HZ

Quick Details

-

Working Table Size(mm):

-

2000×4000

-

Machine Type:

-

CNC Router

-

Range of Spindle Speed(r.p.m):

-

1 - 24000 rpm

-

Positioning Accuracy (mm):

-

0.03 mm

-

Travel (X Axis)(mm):

-

2000 mm

-

Travel (Y Axis)(mm):

-

4000 mm

-

Repeatability (X/Y/Z) (mm):

-

0.03 mm

-

Spindle Motor Power(kW):

-

6kw

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Blue Elephant

-

Voltage:

-

AC380V(Option)

-

Dimension(L*W*H):

-

2000x4000x200mm

-

Power (kW):

-

7.5

-

Weight (KG):

-

1500

-

Model:

-

ELECNC2040

-

Control system:

-

Ncstudio DSP A11, option: Taiwan SYNTEC /LNC controller

-

Driving system:

-

Stepper motor and Leadshine driver, option: Japan YASAKWA Ac servo

-

Work table:

-

Aluminum T-slot & vacuum work table

-

Traveling speed:

-

80m/min

-

Working speed:

-

0-25m/min

-

Re-positioning accuracy:

-

±0.03mm

-

System resolution:

-

±0.0025mm

-

Working accuracy:

-

±0.03mm -

-

Working voltage:

-

220V 1PH/3PH 50HZ/60HZ 380V 3PH 50HZ/ 60HZ

Products Description

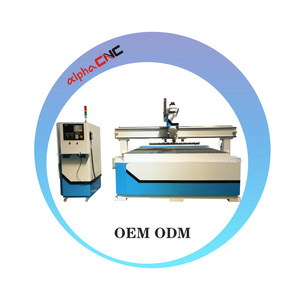

Blue Elephant CNC Automatic 2040 CNC ATC Wood Carving Machine with Tool Changer with Dill Head for Woodworking

Features:

2. This CNC router is equipped with loading rollers which help the loading of heavy wood panels. It is very popular in the panel furniture industry.

3. HSD 9+3+1 drilling head makes the drilling work more effective and convenient.

4. It is a multi-functional machine that will meet various needs. The specifications and configurations can be customized according to customers' demands.

Product Paramenters

|

X,Y axis travel

|

2000x4000mm,

option: 1300x2500, 1500*3000mm; 2000*3000mm; 2000*6000mm, etc. |

|

Z axis travel

|

200mm, option:300mm,400mm,500mm,600mm,etc

|

|

Spindle type

|

Italy 9kw HSD air cooling spindle, ER32

|

|

Inverter type

|

11kw

|

|

Drilling bank

|

Optional

|

|

Tool magazine

|

Carousel Linear type auto tool changer

Option: Linear type auto tool changer

|

|

Tool holder with collet

|

ER32 collet: φ4, φ6, 1/8, 1/2

|

|

Control system

|

Taiwan SYNTEC /LNC controller, option:Ncstudio

|

|

Driving system

|

11kw Japan YASKAWA AC servo driver and 850w AC servo motor,4 sets. option:1kw Taiwan Syntec servo

|

|

Reducer

|

Japan SHIMPO reducer

|

|

Machine structure

|

Heavy duty body with quenching treatment

|

|

Work table

|

Aluminum T-slot & vacuum work table

|

|

Positioning cylinder

|

5 pieces(X2,Y3)

|

|

Linear guide

|

Taiwan Linear guide with dust proof

|

|

Transmission

|

X Y axis: Taiwan / Germany helical rack and pinion

Z axis: Taiwan TBI high precision ball screw |

|

Lubrication system

|

1.5L automatic lubrication system

|

|

Tool calibration

|

Automatic tool sensor calibration

|

|

Cables

|

Germany Igus cables with CE, cUL certificate

|

|

Compatible software

|

Artcam, Alphcam, Type 3, Ucancam, Aspire, etc

|

|

Working voltage

|

220V 1PH/3PH 50HZ/60HZ

380V 3PH 50HZ/ 60HZ |

Product Detalis

Carousel automatic tool changer

The number of tools in the carousel magazine can be customized according to the user's processing requirements. The tool changer can be placed next to the

spindle or on the side of the gantry. This carousel tool change method has the feature of faster tool change speed, so the production effnciency is higher.

CNC Head

ATC CNC router selects Italian HSD air-cooled spindle, power: 9.5KW. Choose from manual, quick-release, high-power and high-speed spindles for optimum processing of rigid sheet materials.

Control system

The control system of CNC router adopts the more advanced Taiwan Syntec system, which is widely acclaimed internationally and can perfectly control 3axis,4, 5, 6, 8axis. The Syntec system can work online and WiFi links, greatly increasing the itelligence of the device.

Driving system

World-class servo motor and driving system ensures machine to run with fast speed and low noise.

Lubricating system

Auto lubricating system, one touch can finish periodic maintenance easily.

Safety system

ATC CNC router has the unique safety protection system and provides external emergency stop function for equipment users. This function can effectively protect the personal safety of the equipment users, meet the European safetyCE standards, and is very popular amongusers.

Sample & Application

Customer Feedback

Hot Searches