- Product Details

- {{item.text}}

Quick Details

-

Features:

-

squashed and broken

-

Production Capacity:

-

200-3000kg/h

-

Dimension(L*W*H):

-

860*450*560

-

Power:

-

2.2-7.5kw

-

Voltage:

-

220v/380v

-

Weight (KG):

-

50

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Wheat squeezing machine

-

Color:

-

Customized

-

Power Type:

-

2.2-7.5KW

-

application:

-

Soybeans, wheat, corn and other grains are crushed and crushed

-

Used for:

-

farm/home use

-

Motor raw materials:

-

Pure copper core

-

model:

-

Various models

-

Power source:

-

motor/diesel engine

-

Other uses:

-

breweries, livestock farms

-

After-sales service:

-

24h on line

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TAIFENG

-

Application:

-

Beans, cereals, etc. squashed and broken

-

Features:

-

squashed and broken

-

Production Capacity:

-

200-3000kg/h

-

Dimension(L*W*H):

-

860*450*560

-

Power:

-

2.2-7.5kw

-

Voltage:

-

220v/380v

-

Weight (KG):

-

50

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Wheat squeezing machine

-

Color:

-

Customized

-

Power Type:

-

2.2-7.5KW

-

application:

-

Soybeans, wheat, corn and other grains are crushed and crushed

-

Used for:

-

farm/home use

-

Motor raw materials:

-

Pure copper core

-

model:

-

Various models

-

Power source:

-

motor/diesel engine

-

Other uses:

-

breweries, livestock farms

-

After-sales service:

-

24h on line

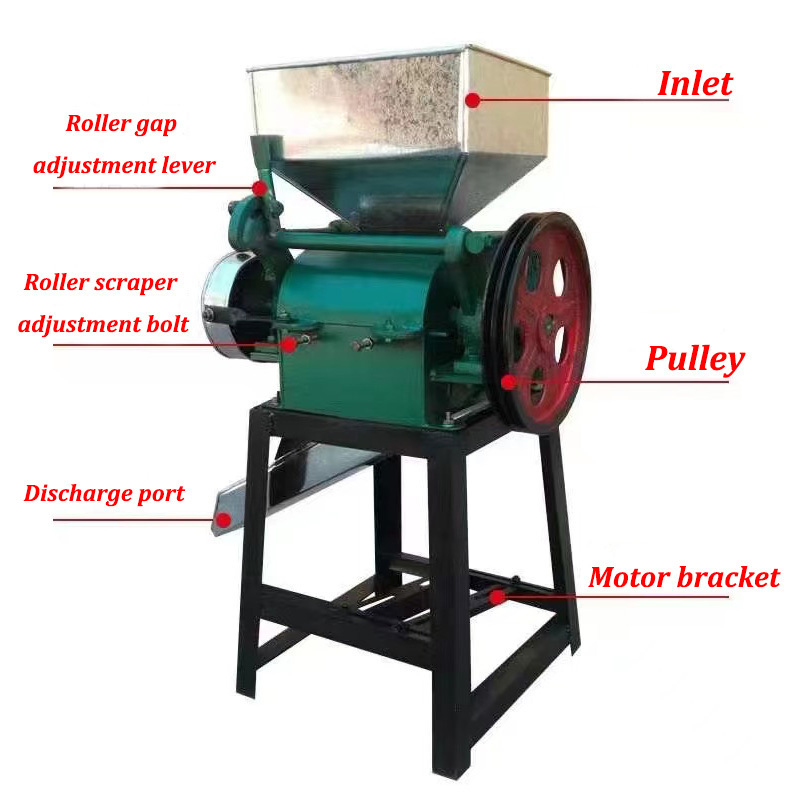

High output Small Grain Wheat Rice Flakes Flattening Machine Corn Barley Oats Flake Grits Making Flaking Machine Plant

Product Overview

Grain and grain squeezing machine

The grain extrusion machine mainly squeezes beans or peeled wheat, rice and other granular grains into flat pieces through wire drawing rollers. It is used for making porridge or soup and is easy to mature. It is an optimal equipment for small-scale grain processing at home. 1: This machine is a double-roller extruder that can process: corn, sorghum, wheat, beans and other grains. It is the best equipment for small-scale grain processing at home. 2: The rollers of this machine are made of hard manganese steel, which has long service life and high efficiency.

Working principle

The bean curing machine has a simple structure, easy operation and small size. Mainly through wire drawing rollers, beans or peeled wheat, rice and other grain grains are squeezed into flat shapes, which are used to make porridge or soup and are easy to mature.

Instructions for use

1. The extruder should be fixed on the cement base for long-term operation. If the working location is changed frequently, the extruder and motor should be installed on a base made of angle iron, and the pulley grooves of the two should be consistent and the outer end faces of the pulleys should be on the same plane.

2. After the extruder is installed, check the tightening condition of each fastener. If there is any looseness, tighten it.

3. Before starting the extruder, first turn the rotor by hand to check whether the roller rotor is flexible and reliable, there is no internal collision, and whether the motor and the bean flat machine are well lubricated.

4. After the extruder is started, it will idle for 2-3 minutes. If there are no abnormal phenomena, it will start feeding.

5. During work, you should always pay attention to the operation of the extruder. The feeding should be uniform to prevent clogging, and do not overload operation for a long time. If any phenomena such as vibration, noise, excessive temperature of the bearings and body, or material spraying out are found, stop the machine immediately for inspection and troubleshoot the problem before continuing to work.

6. Operators should not wear gloves and should stand on the side of the extruder when feeding materials to prevent debris from rebounding and hurting the face.

7. When a blockage occurs, it is strictly forbidden to use hands to feed materials. You should turn off the power first and then find out the cause.

8. After work, the machine should be idle for 2-3 minutes to completely eliminate boredom in the machine.

PRODUCT SPECIFICATIONS

|

Modle

|

Motor

|

Yield

|

|

TF-12-20

|

2.2kw

|

200-300kg/h

|

|

TF-17-28

|

3kw

|

800-1000kg/h

|

|

TF-17-40

|

5.5kw

|

1200-1500kg/h

|

|

TF-17-48

|

5.5kw

|

1800-2500kg/h

|

|

TF-17-60

|

7.5kw

|

2500-3000kg/h

|

Product Pictures

Hot Searches